Manufacturing method for improving extensibility of commonly-cooled ferrite lightweight steel

A technology of ordinary cold ferrite and manufacturing method, which is applied in the field of ferritic light steel, can solve the problems of reducing the bending performance of the steel plate, the overall ductility of the annealed steel plate, and the poor plasticity of the delta ferrite deformation, so as to achieve the optimization of the manufacturing process , good prospects for promotion and application, and the effect of improving tissue uniformity

Active Publication Date: 2015-09-23

BAOSHAN IRON & STEEL CO LTD

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

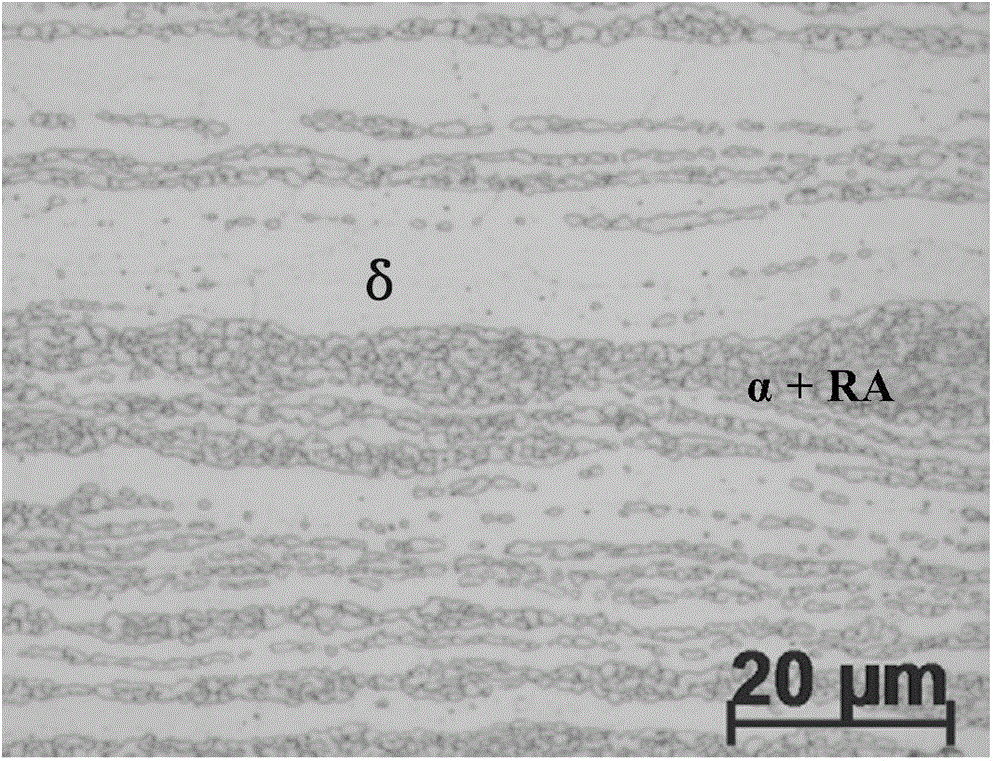

Therefore, although enough metastable retained austenite is distributed in the matrix of the annealed steel plate, due to the poor deformation plasticity of the delta ferrite, the failure mode of the delta ferrite in the annealed steel plate often occurs clea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

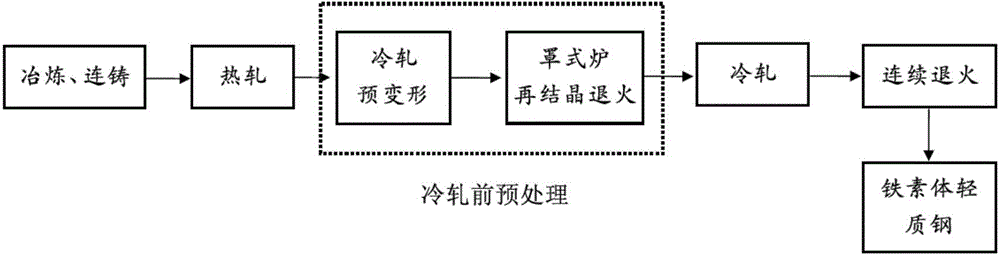

The invention discloses a manufacturing method for improving extensibility of commonly-cooled ferrite lightweight steel. The manufacturing method includes: performing pretreatment before cold rolling, cold rolling and continuous-annealing thermal treatment on thermally-rolled plates, wherein pretreatment before cold rolling includes cold-rolling pre-deformation and recrystallizing annealing. The thermally-rolled steel plates are pretreated before cold rolling to refine high-temperature delta ferrite and improve tissue uniformity of the steel plates after being annealed. By the manufacturing method, high strength of the steel plates is guaranteed while extensibility and strength and elongation product are improved remarkably.

Description

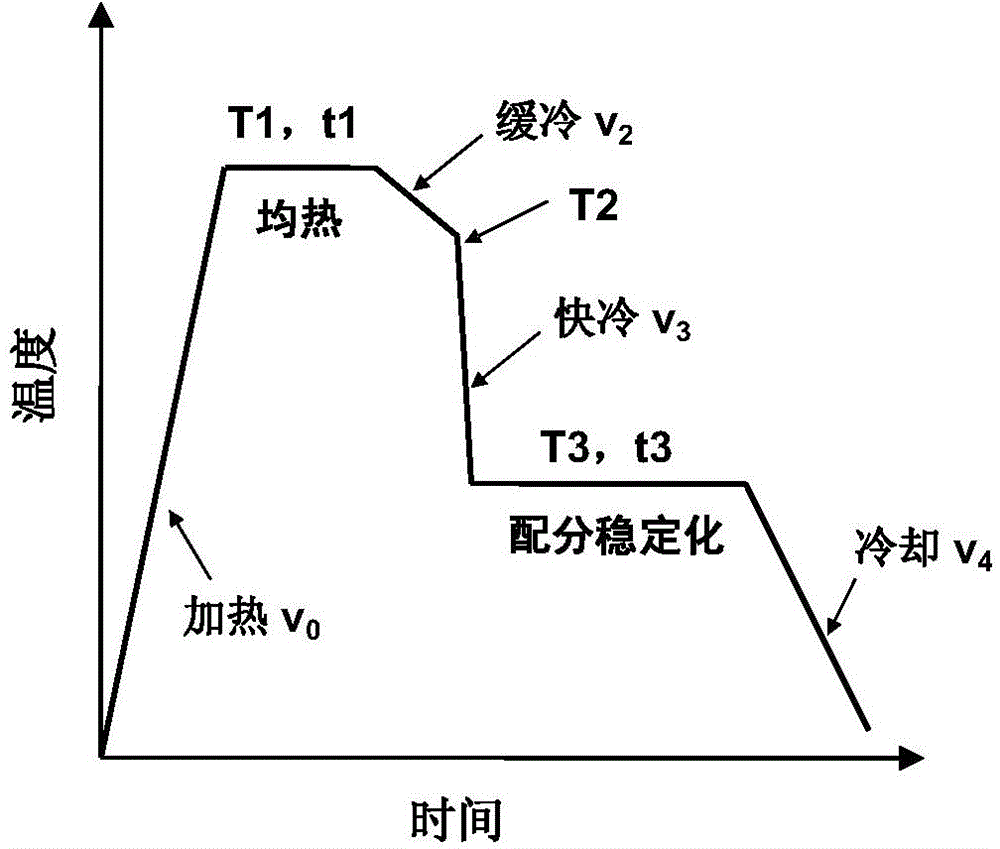

technical field [0001] The invention belongs to the field of ferritic light steel, and in particular relates to a manufacturing method for improving the ductility of ordinary cold ferritic light steel. Background technique [0002] The application of high-strength steel and advanced high-strength steel to replace traditional low-strength grade steel can increase the specific strength (ratio of strength to density) of automotive steel and reduce the thickness of structural parts to achieve lightweight automotive structures. Another effective way to increase the specific strength of automotive steel is to reduce the density of the steel on the basis of maintaining the excellent mechanical properties of the above-mentioned high-strength steel. Therefore, the development of low-density, high-strength and toughness steel plates is just to meet the urgent need to further realize the lightweight of automobiles. [0003] Low-density steel generally reduces the density of carbon ste...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D8/00C21D6/00C22C38/58C22C38/54

Inventor 杨旗毕文珍王国栋王利

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com