Compact EGR (exhaust gas recirculation) channel structure

A channel-structured and compact technology, applied in the field of EGR system, can solve the problems of high manufacturing cost, limited space layout, and difficulty in achieving the balance of multi-cylinder EGR intake rate, etc., and achieve a good manufacturing process and a balanced exhaust gas volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

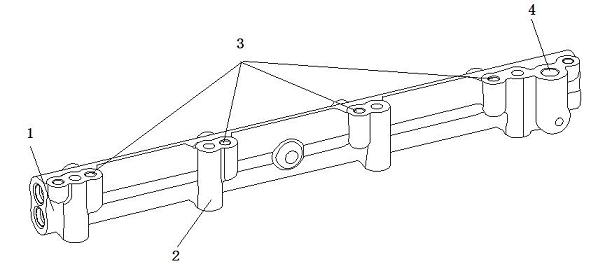

[0025] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0026] Such as figure 1 As shown, the EGR passage structure 1 includes an EGR intake hole 4 and a plurality of EGR outlet holes 3, and the plurality of EGR outlet holes 3 respectively enter each cylinder body through the engine intake passage, and realize the balance of EGR exhaust gas entering each cylinder .

[0027] Mounting bolt holes 2 are provided on the EGR channel structure 1 , and the EGR channel structure 1 is fixed on the engine cylinder head through the cooperation of the bolts and the mounting bolt holes 2 .

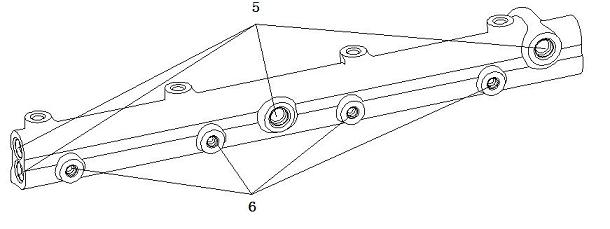

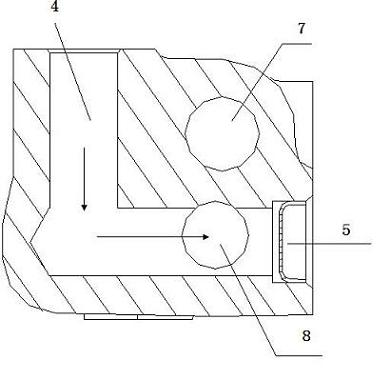

[0028] Such as figure 2 As shown, when the EGR passage structure 1 is formed by machining or casting, a plurality of first bowl-shaped plugs 5 and a plurality of second bowl-shaped plugs 6 are formed on the intake passage 8 and the outlet passage 7 . The first bowl-shaped plug 5 and the second bowl-shaped plug 6 are plugs or steel balls.

[0029] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com