Lower base plate of double-layer turnout vibration damping fastener and manufacturing method of lower base plate

A technology for damping fasteners and manufacturing methods, which is applied in the field of rail transit, can solve problems such as reducing welding strength, destroying the microstructure of substrate microstructures, and cracking of welds, so as to achieve the effect of optimizing the manufacturing process and improving the stability of weld structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

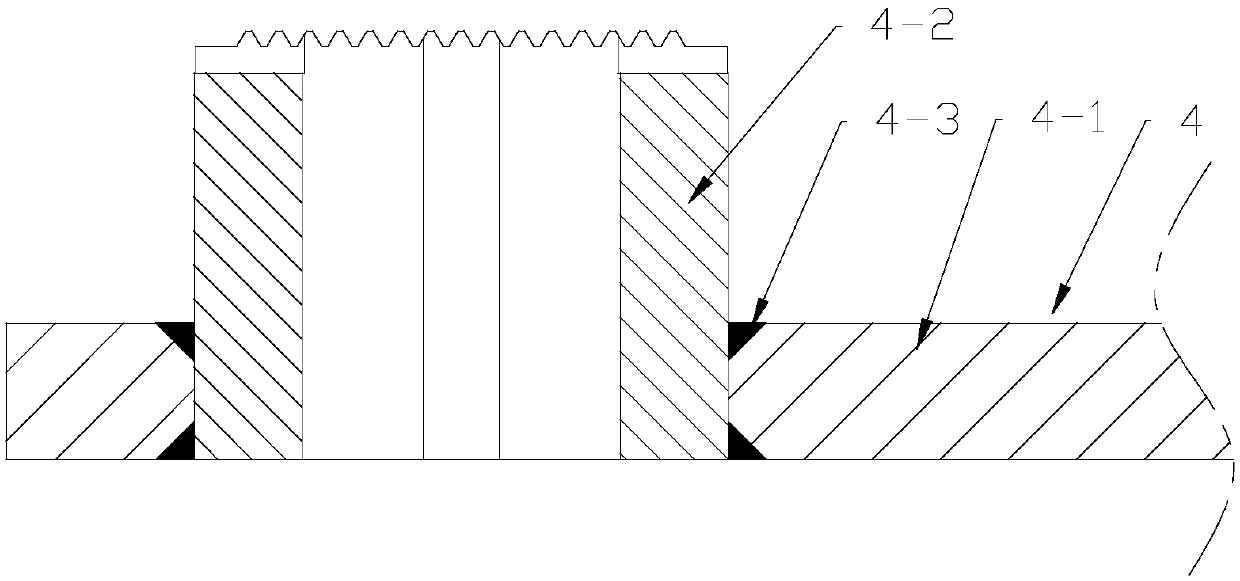

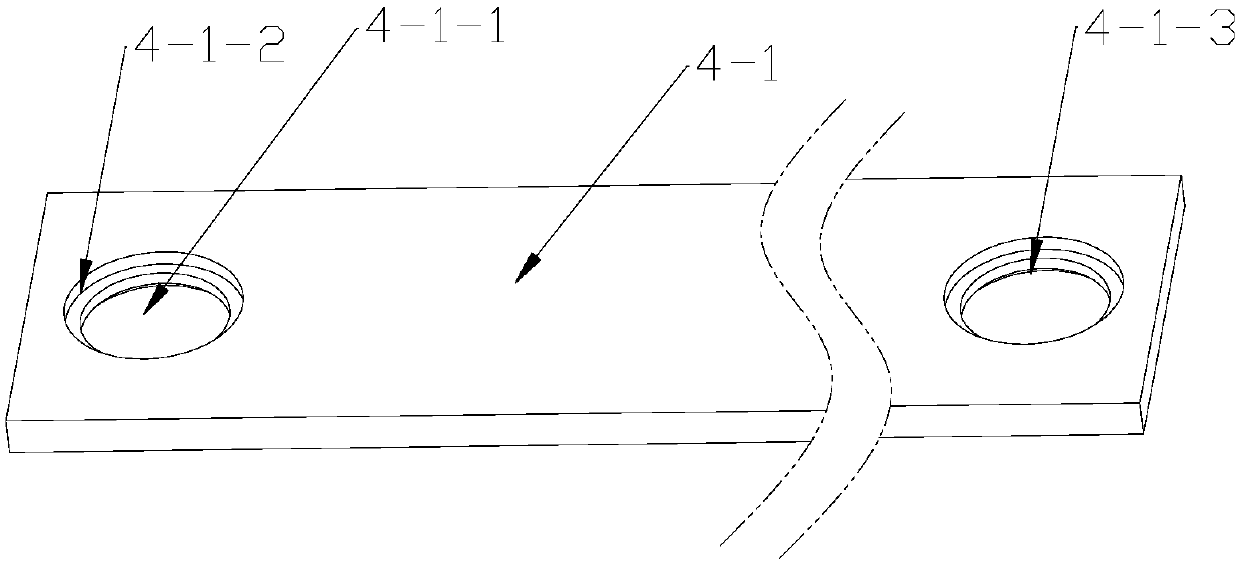

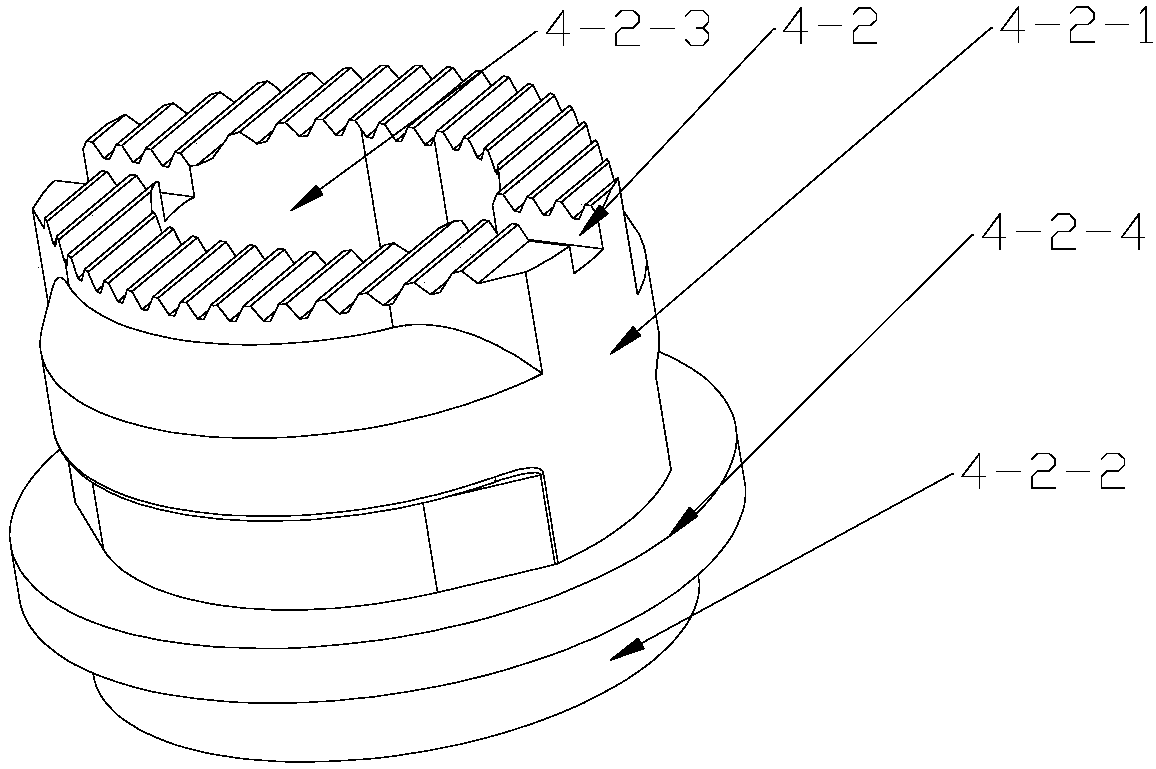

[0065] Combine figure 2 , image 3 , Figure 4 As shown, the first embodiment of the present invention provides a double-layer switch damping fastener lower backing plate, which includes a base plate 4-1 and a locking boss 4-2 that are connected by welding; the base plate 4-1 is provided with a through hole 4- 1-1, the top end of the through hole 4-1-1 is provided with a first annular step 4-1-2, and the bottom end of the through hole 4-1-1 is provided with a first annular chamfer 4-1-3 or first Circular round; the locking boss 4-2 includes a locking boss 4-2-1 and a welding part 4-2-2 connected to each other, and the welding part 4-2-2 is used to be inserted into the through hole 4-1-1 In 1, above the welding portion 4-2-2 is provided with a second annular step 4-2-4 that closely fits the first annular step 4-1-2; the first annular step at the bottom of the through hole 4-1-1 The chamfer 4-1-3 or the first circular round and the locking boss 4-2 are connected by welding.

[00...

Embodiment 2

[0086] The second embodiment of the present invention provides a double-layer switch damping fastener lower backing plate. The main structure is similar to that of the first embodiment. For the specific configuration of the main structure, please refer to the detailed record in the first embodiment. The difference between the two.

[0087] Combine Figure 5 , Image 6 As shown, in this embodiment, the bottom end of the locking boss 4-2 is provided with a second circular chamfer 4-2-5 or a second circular chamfer, the first circular chamfer 4-1-3 or a second circular chamfer The area between an annular round and the second annular chamfer 4-2-5 or the second annular round fills the welding area, that is, the weld 4-3 in this embodiment has a larger volume.

[0088] In the specific operation, the setting of the above-mentioned second annular chamfer 4-2-5 or second annular rounding can effectively increase the space size of the filling welding area, thereby effectively improving the ...

Embodiment 3

[0090] Combine Figure 7 , Figure 8 As mentioned, the third embodiment of the present invention provides a double-layer switch damping fastener, which includes the lower pad 4 described in the first or second embodiment, and also includes the under-rail elastic pad 6, the upper pad 2, the middle It is composed of elastic pad 3, locking nylon sleeve 9, adjustable pitch cover 7, coupling pad 5, insulating gauge block 11, elastic strip 8, anchoring system and other components.

[0091] In this embodiment, the upper backing plate 2 is provided with sliding bed boards, rail supports, 8 spring bars, etc., and at the same time is provided with through holes. The upper backing plate 2 is connected to the rail 1 through the spring bars 8 and the insulating gauge block 11 and is fixed on the rail 1. Together; the middle elastic pad 3 is provided with a number of elastic elements on the base plate, and is provided with a through hole for the locking boss of the lower pad 4 to penetrate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com