A kind of glasses leg and preparation process thereof

A technology of spectacle legs and titanium zinc, which is applied in the field of glasses, can solve the problems of unsightly appearance and aging of spectacle legs, and achieve the effect of smooth surface, not easy to damage, and conducive to large-scale production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

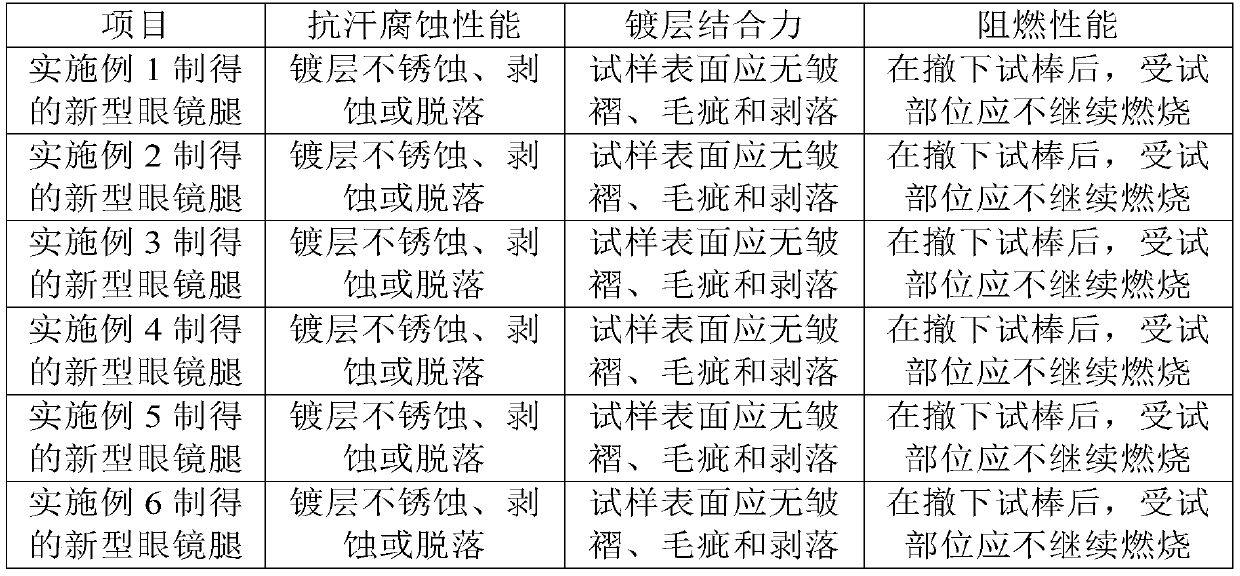

Examples

Embodiment 1

[0027] A new type of spectacle leg, using ceramic material as the substrate of the new spectacle leg, and electroplating titanium-zinc alloy on the surface of the substrate; the ceramic material is prepared from the following raw materials in parts by weight: 35 parts of magnesium oxide, 20 parts of aluminum oxide, and 18 parts of carbon fiber 5 parts, 5 parts of polyvinyl alcohol, 1 part of dodecylalanine; The mass fraction of titanium in the titanium-zinc alloy is 28%, and the rest is zinc;

[0028] Wherein, the purity of magnesium oxide is 98%; the purity of aluminum oxide is 98%; the binder is polyvinyl alcohol; the surfactant is dodecylalanine.

Embodiment 2

[0030] A new type of spectacle leg, using ceramic material as the substrate of the new spectacle leg, and electroplating titanium-zinc alloy on the surface of the substrate; the ceramic material is prepared from the following raw materials in parts by weight: 50 parts of magnesium oxide, 35 parts of aluminum oxide, and 23 parts of carbon fiber parts, 10 parts of binder, 3 parts of surfactant; the mass fraction of titanium in the titanium-zinc alloy is 36%, and the rest is zinc;

[0031] Among them, the purity of magnesium oxide is 98.5%; the purity of aluminum oxide is 98.5%; the binder is polyvinyl alcohol and polyethylene vinyl acetate; the plasticizer is stearic acid and dioctyl adipate; the surfactant It is dodecylalanine and cetyltrimethylammonium bromide.

Embodiment 3

[0033] A new type of spectacle leg, using ceramic material as the substrate of the new spectacle leg, and electroplating titanium-zinc alloy on the surface of the substrate; the ceramic material is prepared from the following raw materials in parts by weight: 42 parts of magnesium oxide, 28 parts of aluminum oxide, and 20 parts of carbon fiber part, 7 parts of binder, 2 parts of surfactant; the mass part of titanium in the titanium-zinc alloy is 32%, and the rest is zinc;

[0034] Among them, the purity of magnesium oxide is 99%; the purity of aluminum oxide is 99%; the binder is polyvinyl alcohol, polyethylene vinyl acetate, polyacrylate; the plasticizer is stearic acid, dioctyl adipate , ethylene glycol; surfactants are cetyltrimethylammonium bromide, polyvinylpyrrolidone, sodium ethylenediaminetetraacetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com