Intelligent safety sucker, self-moving adsorption system, and control method thereof

A control method and adsorption system technology, applied in suction cups, connecting components, cleaning equipment, etc., can solve problems such as the inability to guarantee the safety of the suction cup impact force, damage to the window cleaning robot, and injury to passers-by.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

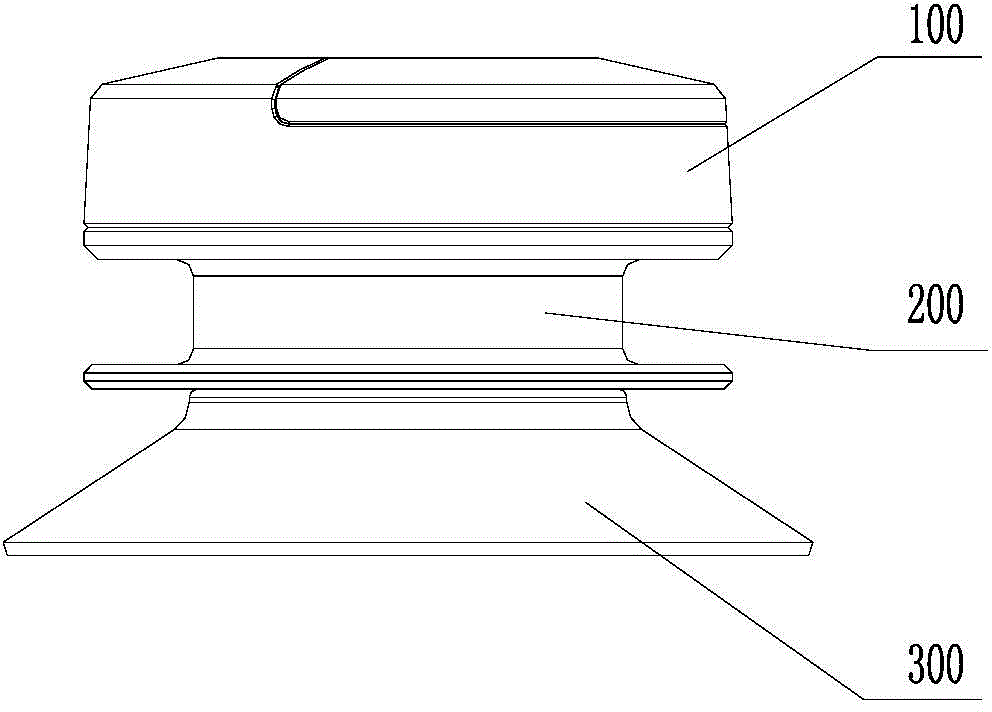

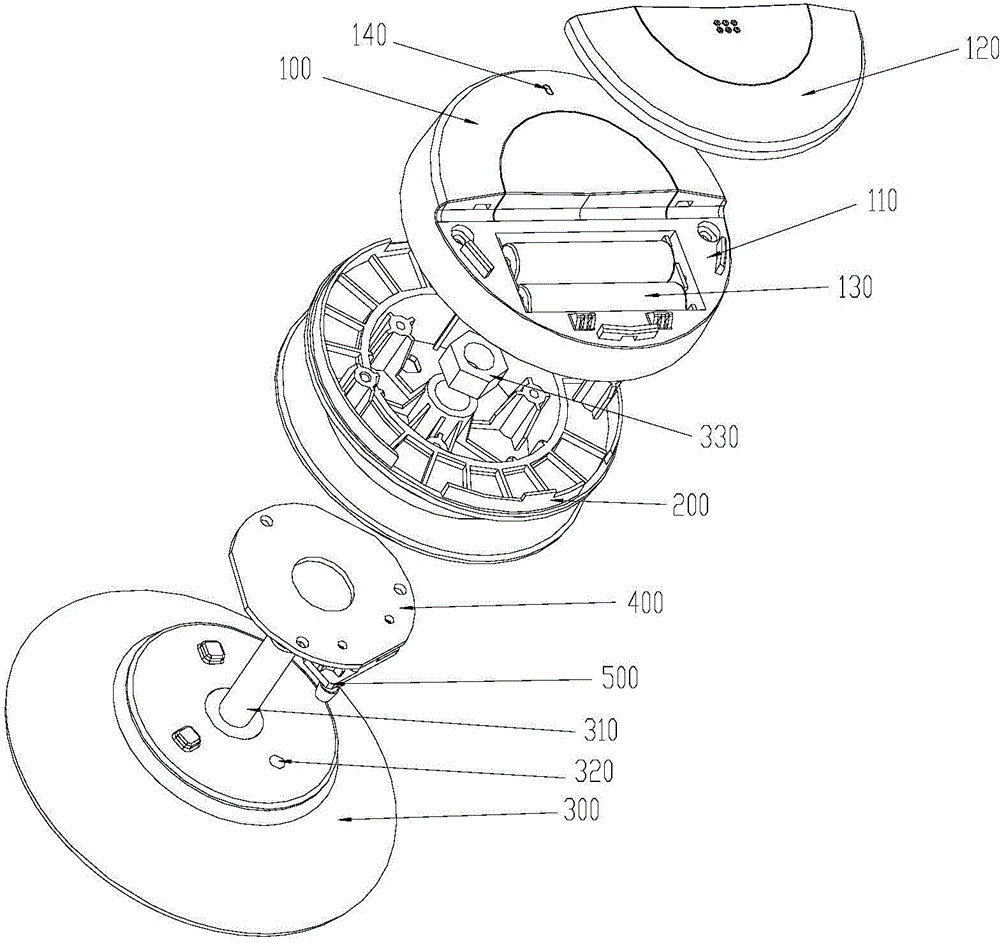

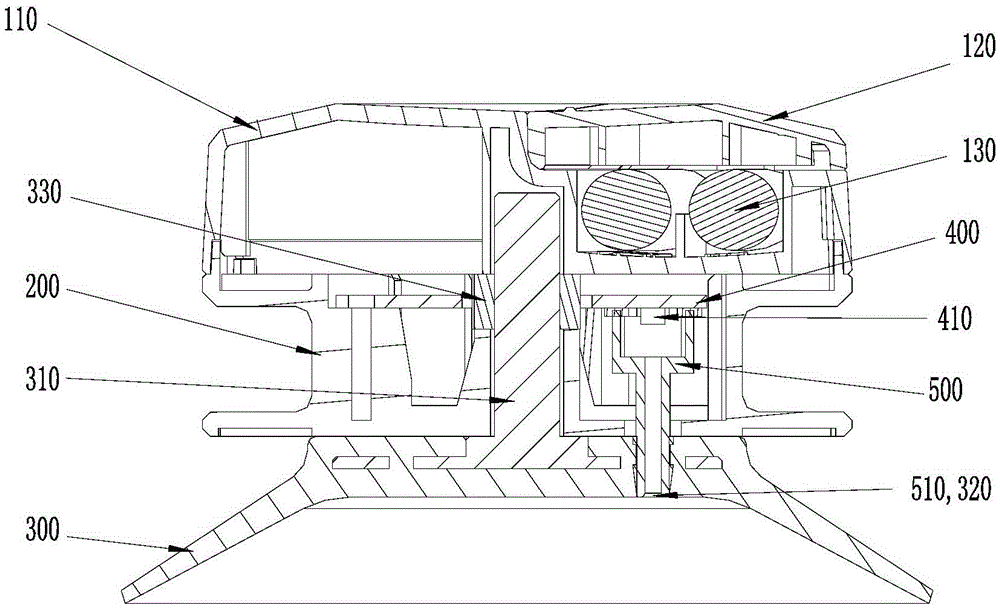

[0033] The present invention also provides a self-moving adsorption system, which includes a safety suction cup assembly and a self-moving adsorption device body, a safety rope is fixed on the safety suction cup assembly, and the self-moving adsorption device body is connected to the safety suction cup assembly through a safety rope. The suction cup assembly is the aforementioned intelligent safety suction cup, the first control unit is integrated on the circuit board, and the vacuum sensor is electrically connected to the first control unit.

[0034] The present invention further provides a control method for a self-moving adsorption system, the system includes a self-moving adsorption device body A and a safety suction cup assembly B connected to it through a safety rope 1000, and the control method includes the following steps:

[0035] Step 100: Press the safety suction cup assembly on the working surface, and the vacuum sensor sends the detection value of the vacuum degree d...

Embodiment 2

[0040] Figure 4 It is a structural schematic diagram of the self-moving adsorption system of the present invention. like Figure 4 As shown, the present invention also provides a self-moving adsorption system, including a self-moving adsorption device body A and a safety suction cup assembly B, a safety rope 1000 is fixed on the safety suction cup assembly B, and the self-moving adsorption device body A passes through the safety rope 1000 Connect with safety suction cup assembly B. The safety suction cup assembly B is the above-mentioned intelligent safety suction cup. In order to facilitate the communication between the safety suction cup assembly and the self-moving adsorption device body, a first signal terminal is arranged on the circuit board in the suction cup base; A control unit is provided on the body of the mobile adsorption device, and a second signal terminal is provided on the control unit, and the first signal terminal is electrically connected to the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com