Air conditioner mounting rack

A mounting frame and air-conditioning technology, which is applied in the field of mounting frames, can solve the problems of poor working conditions, high labor intensity and danger, and troublesome installation, disassembly and moving of installers, and achieve the effects of low cost, simple structure, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

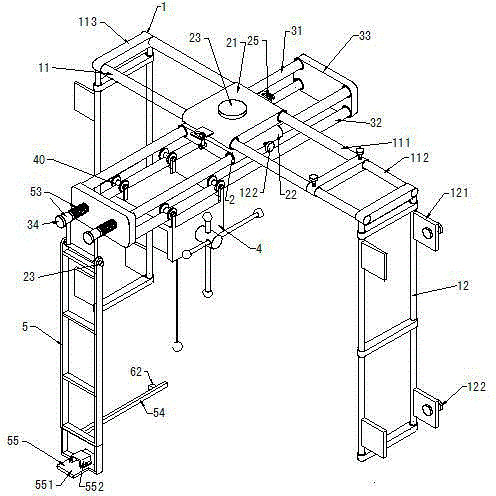

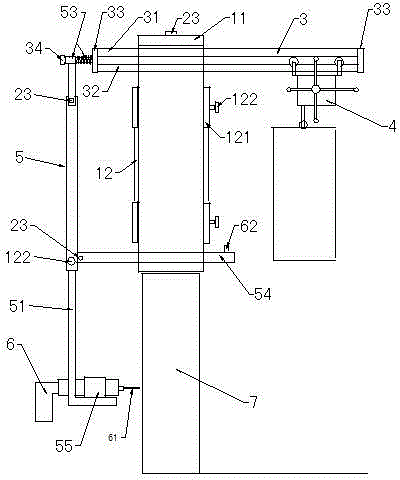

[0028] As shown in the figure, the air conditioner installation frame includes a fixed frame 1 , a movable plate 2 , a hanger 3 , a lifting device 4 , and a pressing arm 5 .

[0029] 1. Fixed frame.

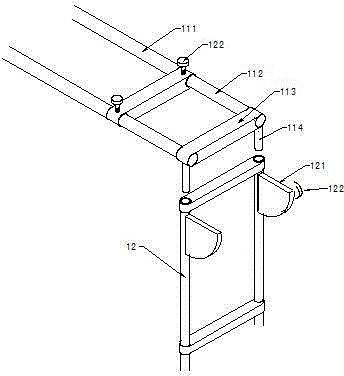

[0030] Such as figure 1 As shown, taking the frame of the double-tube structure as an example, the fixed frame 1 is in the shape of "Π" when it is opened, and the horizontal frame 11 is a telescopic double-tube frame, and its structure is that the two ends of the parallel double outer tubes 111 are fixedly connected to the connecting rods 113, One end of the double nozzle is inserted into the corresponding parallel double inner pipe 112, the other end of the inner pipe is fixedly connected to the connecting rod 113, the mullion 12 is fixedly connected to the connecting rod 113 between the parallel double vertical pipes, and the two sides of the frame are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com