A device for testing the outlet flow rate of the main oil passage of a planetary transmission mechanism

A technology of planetary speed change and outlet flow, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of inability to observe the flow state of lubricating oil flow field, not considering the influence of the main oil passage, etc., to achieve simple and easy installation and maintenance, and improve the reliability. Reliability, promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

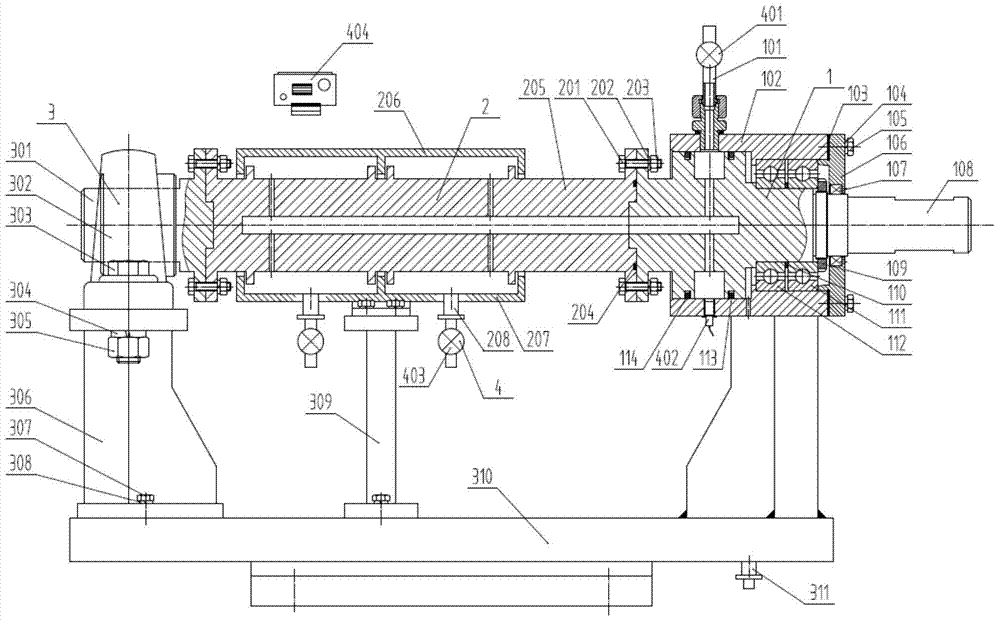

[0052] The drive assembly 1 includes an oil inlet pipe assembly 101, a bearing seat 102, a gasket 103, a spring washer I104, a screw I105, a bearing end cover 106, a lip seal 107, an input shaft 108, a pressure plate 109, a shaft sleeve 110, a bearing A111, bearing B112, sealing ring A113 and sealing ring B114;

[0053] The bearing seat 102 is a cylinder with a stepped hole, and two radial through holes are opened on the outer peripheral surface of the cylinder along its circumference;

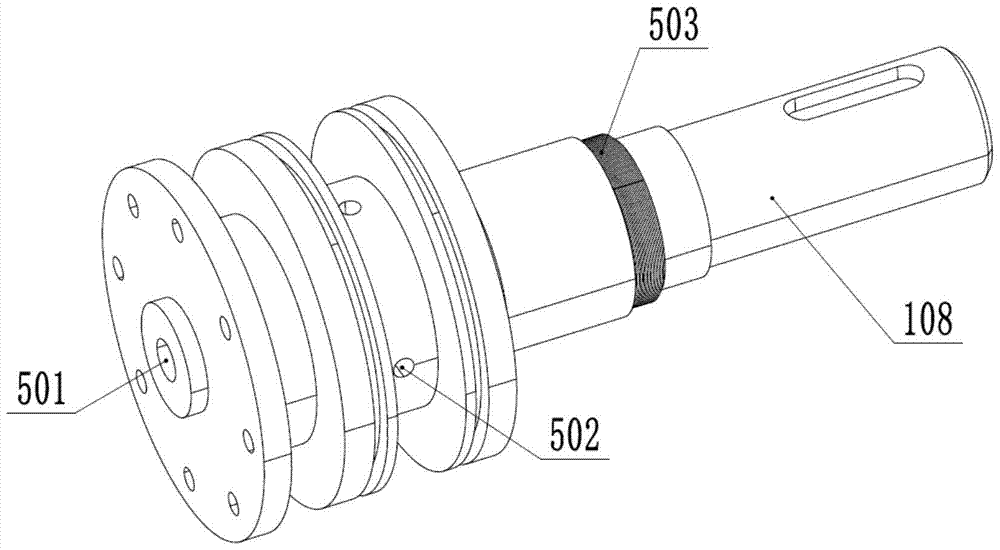

[0054] See attached image 3 , the input shaft 108 is a stepped shaft with a blind hole along its axial direction, an annular groove along the circumference of the large diameter section of the stepped shaft, and an annular groove along the bottom surface of the annular groove. The radial through holes distributed in the circumferential direction, the radial through holes and the blind holes are connected to form the oil inlet hole 502; the middle part of the input shaft 108 is processed with...

Embodiment 2

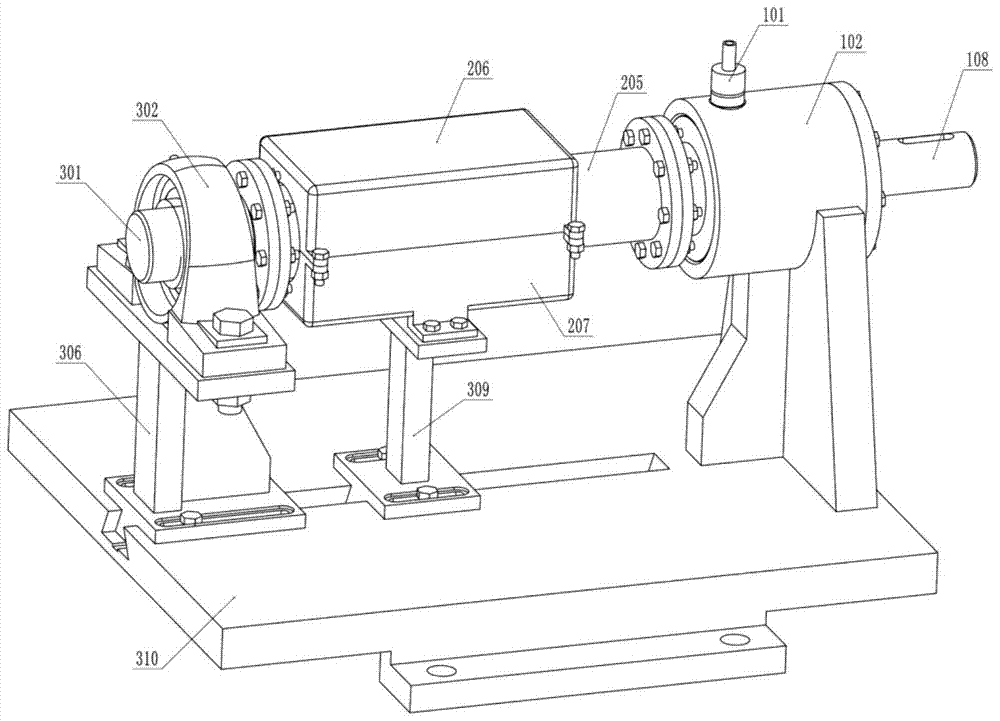

[0074] Drive assembly 1, support assembly 3 and measuring instrument assembly 4 in the present example are all identical with the structure in embodiment 1; See attached Figure 5 , the length of the test shaft 205 in the present embodiment increases, the number of oil outlet holes 504 increases, and the length of the corresponding test case loam cake 206 and the test case base 207 also increases, and the test case base 207 is installed The number of the oil outlet pipe assembly 208 increases, and the number changes from 2 to 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com