Paste filling material conveying state online monitoring system

A technology of conveying state and paste filling, applied in the field of online monitoring, can solve problems such as pipe blockage accidents and poor conveying performance, and achieve the effect of accurate pressure difference and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below with reference to specific embodiments.

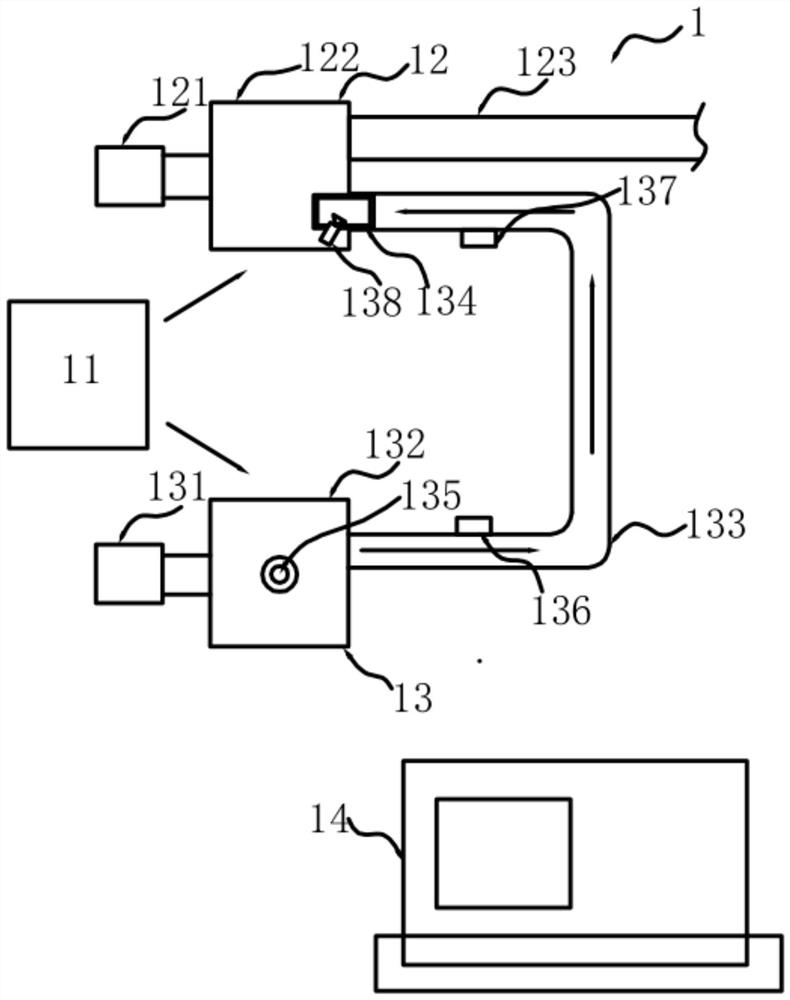

[0030] like figure 1 As shown, the first embodiment of the present invention discloses an on-line monitoring system 1 for the conveying state of paste filling materials, which is mainly used in the coal mining industry to perform ground pressure maintenance on gobs by using paste filling method. Online monitoring of conveying status. The on-line monitoring system 1 for the conveying state of paste filling material includes a batching bin 11 , a main conveying pipeline 12 , an on-line monitoring device 13 , and a monitoring platform 14 . The ingredient bin 11 is mainly used to store the paste filling that has been stirred evenly. The on-line monitoring device 13 is bypassed on the main conveying pipeline 12 . The main conveying pipeline 12 and the online monitoring device 13 respectively introduce the paste filling material from the batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com