Ventilating member for photoelectric instrument

A technology of photoelectric instruments and components, applied in the direction of casings/cabinets/drawer components, etc., can solve problems such as unfavorable use and maintenance of photoelectric instruments, instrument pressure difference, and adverse effects of photoelectric instruments on precision work, etc., to achieve simple implementation, Eases pressure changes and improves sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

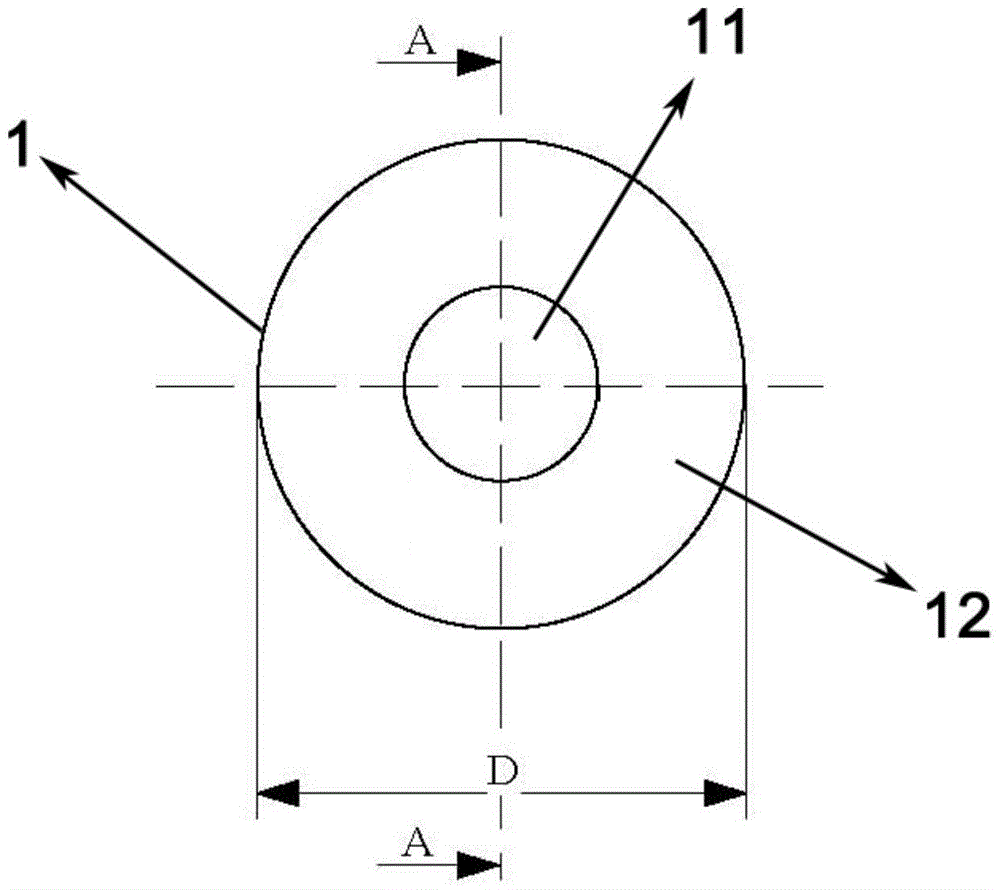

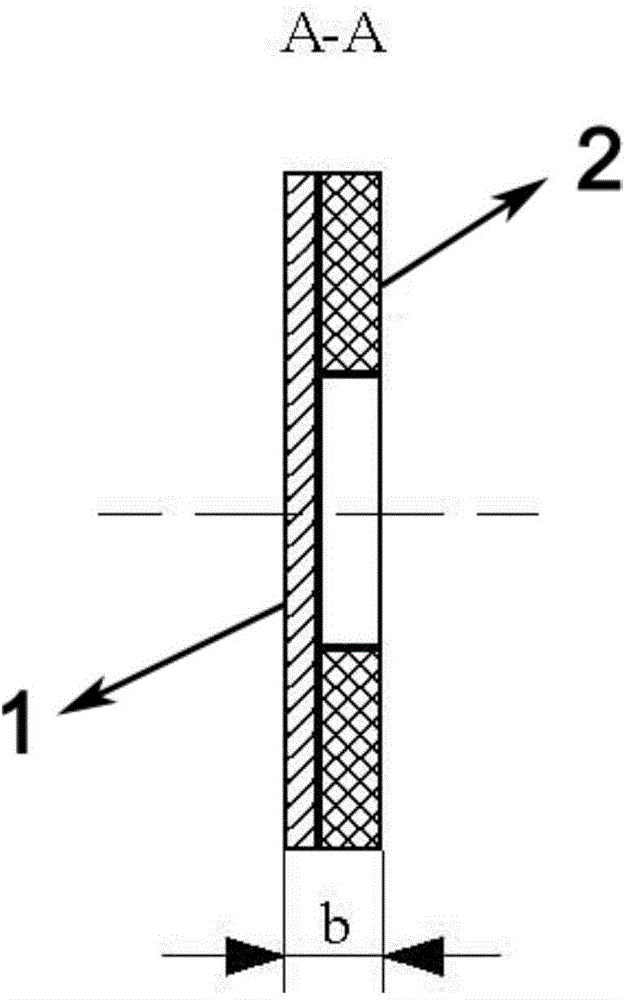

[0020] like figure 1 As shown, the present invention discloses a gas-permeable component for an optoelectronic instrument, which is installed at a reasonable position on the housing of the optoelectronic instrument, usually on a vent hole (not shown) communicating with the outside of the optoelectronic instrument. The air-permeable component comprises a breathable film 1 and an adhesive tape 2, wherein the adhesive tape 2 is arranged around the air hole, and the air-permeable film 1 is fixed on the adhesive tape 2 to cover the air hole. At this time, the air-permeable film 1 and the adhesive tape The combined bands 2 jointly constitute a ventilating component, and perform the function of pressure compensation in the vent hole of the photoelectric instrument. refer to figure 1 It can be seen that the breathable film 1 is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com