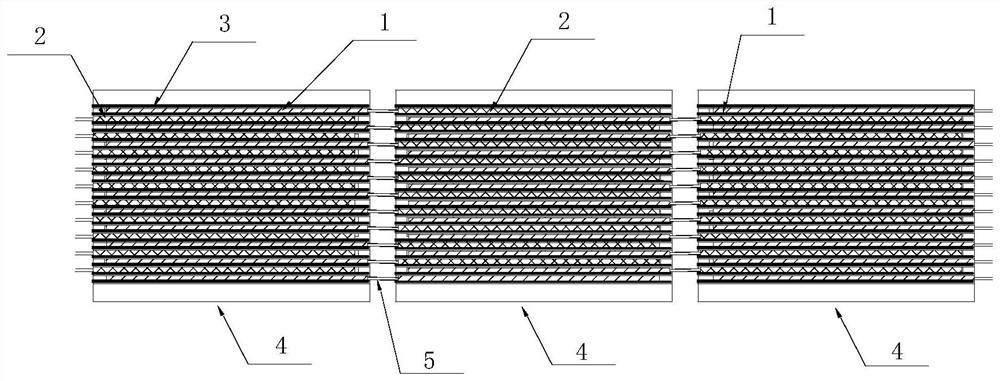

Composite separator for horizontal lead-acid battery, horizontal lead-acid battery comprising same and assembling method of horizontal lead-acid battery

A lead-acid battery and assembly method technology, applied in lead-acid battery, lead-acid battery construction, battery pack components and other directions, can solve the problem of easy deformation and instability of the separator structure, affecting battery life, increasing battery self-discharge, etc. problems, to achieve commercial production and application, improve group consistency, and reduce the effect of self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

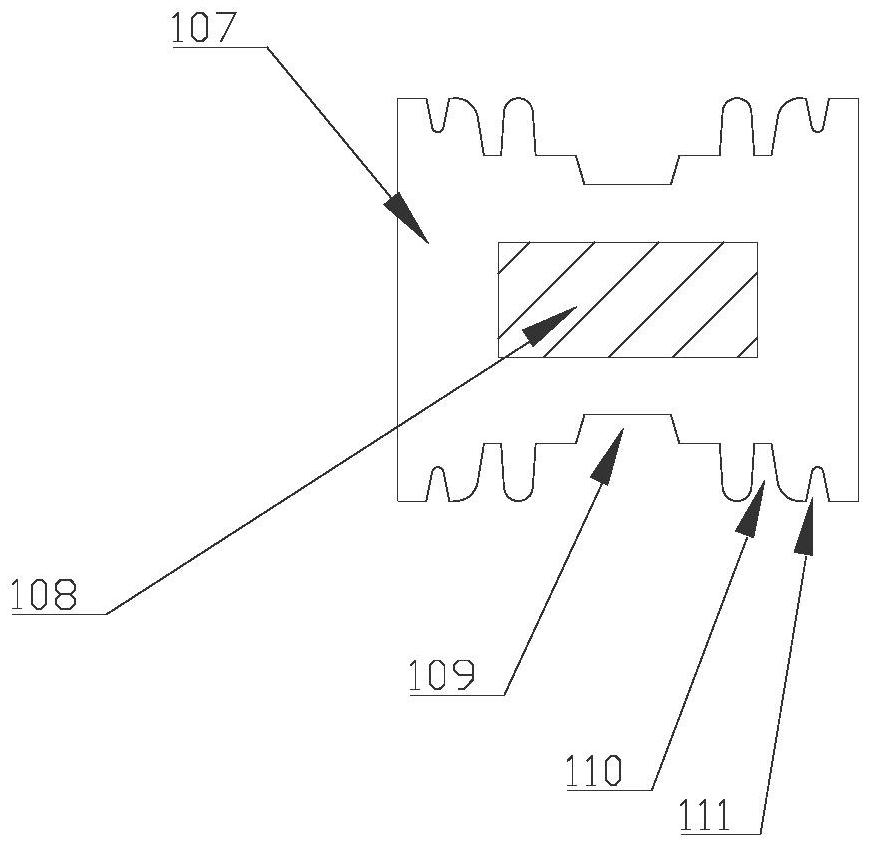

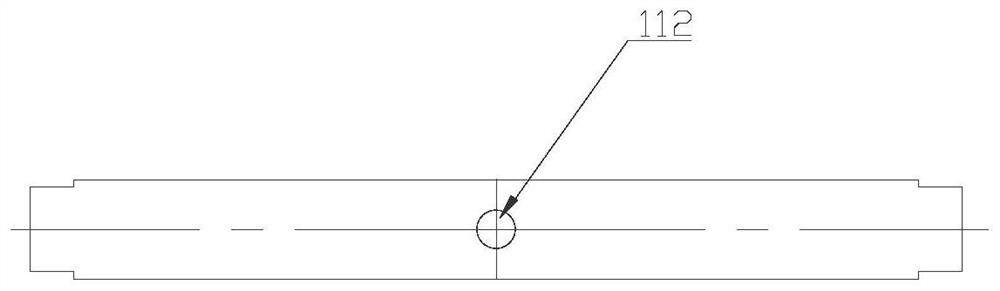

[0042] Composite separator 106 for horizontal lead-acid batteries, such as Figure 2-4 As shown, the strip structure is composed of the elastic matrix 107 and the insert 108 wrapped inside the elastic matrix 107. The height of the strip structure is equal to the distance between the horizontal lead-acid battery plates, and the lead wire can be drawn from two Adjacent composite separators 106 pass through without damage. Among them, the elastic matrix 107 is made of silicone rubber with an elastic modulus of about 25Mpa, and the insert is made of acid-resistant stainless steel rigid material, which is a plate-shaped integral structure with a rectangular cross section.

[0043] Both the upper end and the lower end of the bar-shaped structure are provided with a left and right through for accommodating a sealant-containing groove 109, and both sides of the glue-containing groove 109 are provided with a first sealing groove 110 and a second sealing groove 111, The depth of the se...

Embodiment 2

[0048] A composite separator for a horizontal lead-acid battery, the side schematic of which is shown in Figure 5 As shown, the strip structure is composed of the elastic matrix 207 and the insert 208 wrapped inside the elastic matrix 207. The height of the strip structure is equal to the distance between the horizontal lead-acid battery plates, and the lead wire can be drawn from two Pass through without damage between adjacent composite spacers. Among them, the elastic matrix 207 is made of EPDM rubber with an elastic modulus of about 35Mpa, and the insert is made of bakelite rigid material, which is an integrated structure with a "U" shape in cross section.

[0049] The lower end of the bar-shaped structure is provided with a left-right penetrating glue-holding groove 209 for accommodating the sealant, and first sealing grooves 210 are arranged on both sides of the glue-holding groove 209, and the depth of the first sealing groove 210 is less than the depth of the sealant....

Embodiment 3

[0051] A composite separator for a horizontal lead-acid battery, the side schematic of which is shown in Figure 6 As shown, the strip structure is composed of the elastic matrix 307 and the insert 308 wrapped inside the elastic matrix 307. The height of the strip structure is equal to the distance between the horizontal lead-acid battery plates, and the lead wire can be drawn from two Pass through without damage between adjacent composite spacers. Among them, the elastic matrix 307 is made of butadiene rubber with an elastic modulus of about 40Mpa, and the insert is made of polytetrafluoroethylene rigid material, which is an integral structure with an "I" shape in cross section.

[0052] Both the upper end and the lower end of the bar-shaped structure are provided with left and right penetrating adhesive grooves 309 for accommodating the sealant, and a first sealing groove 310 and a second sealing groove 311 are arranged on both sides of the adhesive groove 309, The depth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com