Electrophoretic paint capable of preventing adhesion of liquid and bacteria and application method of electrophoretic paint

A technology of bacterial adhesion and electrophoresis paint, applied in the field of electrophoresis paint, can solve problems such as unfavorable sustainable development and unfriendly environment, and achieve the effects of good wear resistance and flexibility, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention relates to a kind of electrophoretic paint for preventing liquid and bacteria from adhering, and its preparation method comprises the following steps:

[0040] S1, respectively prepare high hydroxyl value water-soluble cationic resin and silicon modified crosslinking component, wherein:

[0041] The preparation method of the high hydroxyl value water-soluble cationic resin is:

[0042] In parts by weight, 0.2 part of azobisisobutyronitrile was used as an initiator, and 50 parts of propylene glycol methyl ether acetate were mixed and stirred as a solvent, and the temperature was raised to 100 ° C and kept at a temperature. After mixing the cationic monomer and the cross-linking monomer, add dropwise at a constant rate for 0.5 h, then, heat up to 110 ° C, add 0.2 part of azobisisobutyronitrile, keep the temperature for 15 h, cool down to room temperature, add lactic acid to neutralize to pH value is 7.6, that is, the high hydroxyl ...

experiment example

[0054] The anti-liquid and bacterial adhesion properties of the coatings prepared in Examples 1-4 were tested, specifically:

[0055] 1. Anti-liquid performance

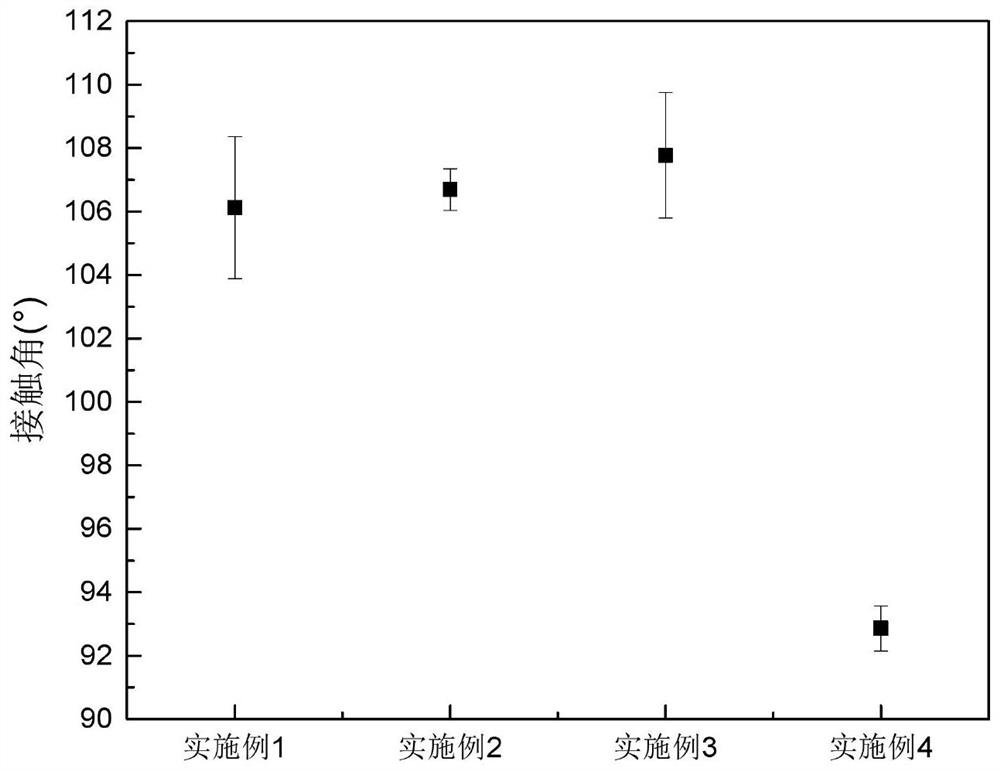

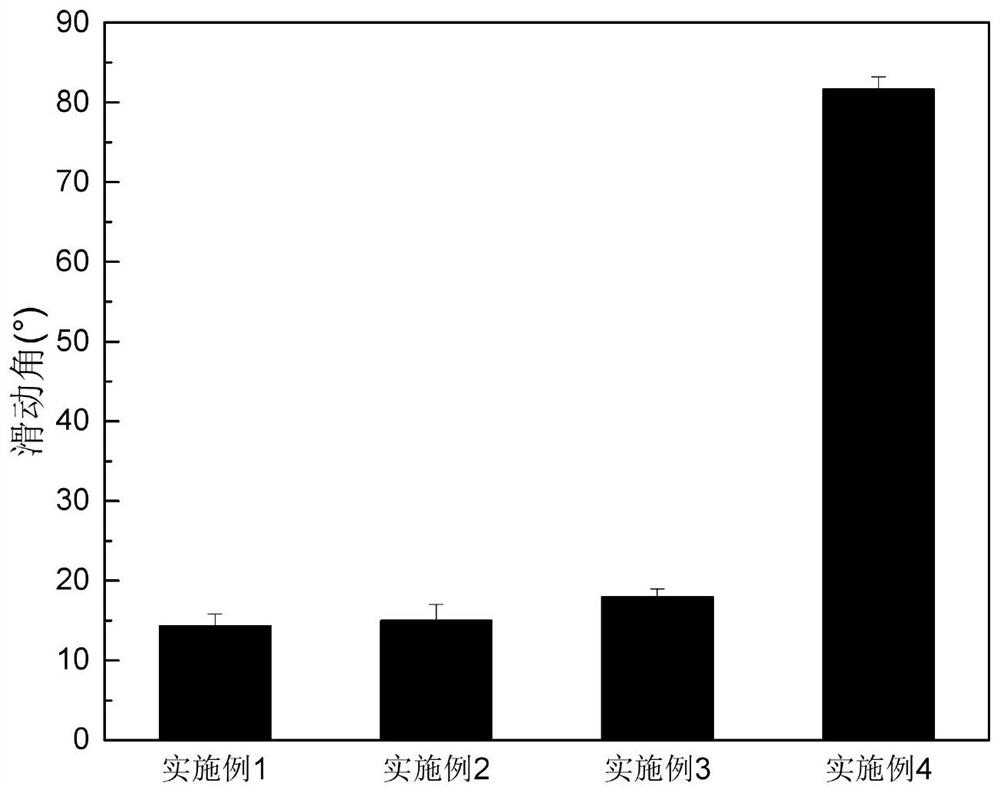

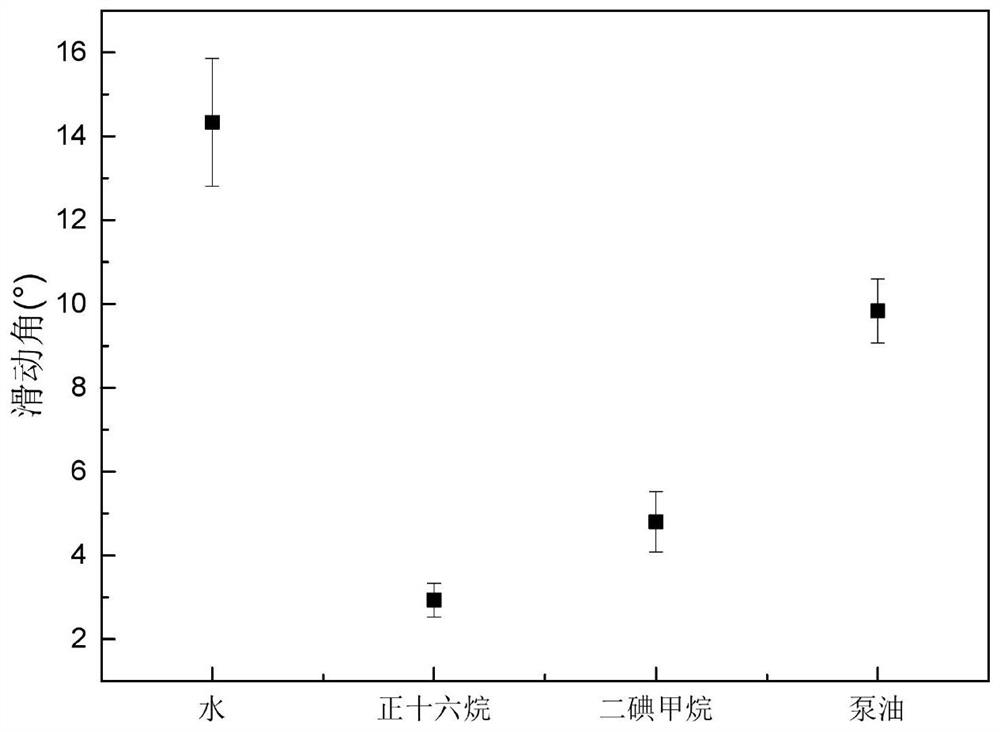

[0056] see attached Figure 1-2 , with Figure 1-2For the water contact angle and sliding angle tests of Examples 1-4, the test liquid required for the contact angle is 2 μL, and the test liquid required for the sliding angle is 50 μL. By comparing Examples 1 and 4, it can be seen that the sliding angle is significantly reduced after adding PDMS. With the increase of PDMS addition (1-5%), the water contact angle and sliding angle of the coating increased. When the amount of PDMS is 0.015g (1%), it has good anti-liquid adhesion performance. If the amount of PDMS continues to increase, macroscopic phase separation will occur due to the poor compatibility of PDMS chains in the polymer system, resulting in performance decline. By comparing Example 4 and Example 1, it can be seen that after adding PDMS, the water cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com