Combine harvester

A technology for combine harvesters and harvesting devices, which is applied to harvesters, cutters, agricultural machinery and implements, etc., and can solve problems such as inability to easily drive maintenance and repair operations, and reduced safety in harvesting and threshing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

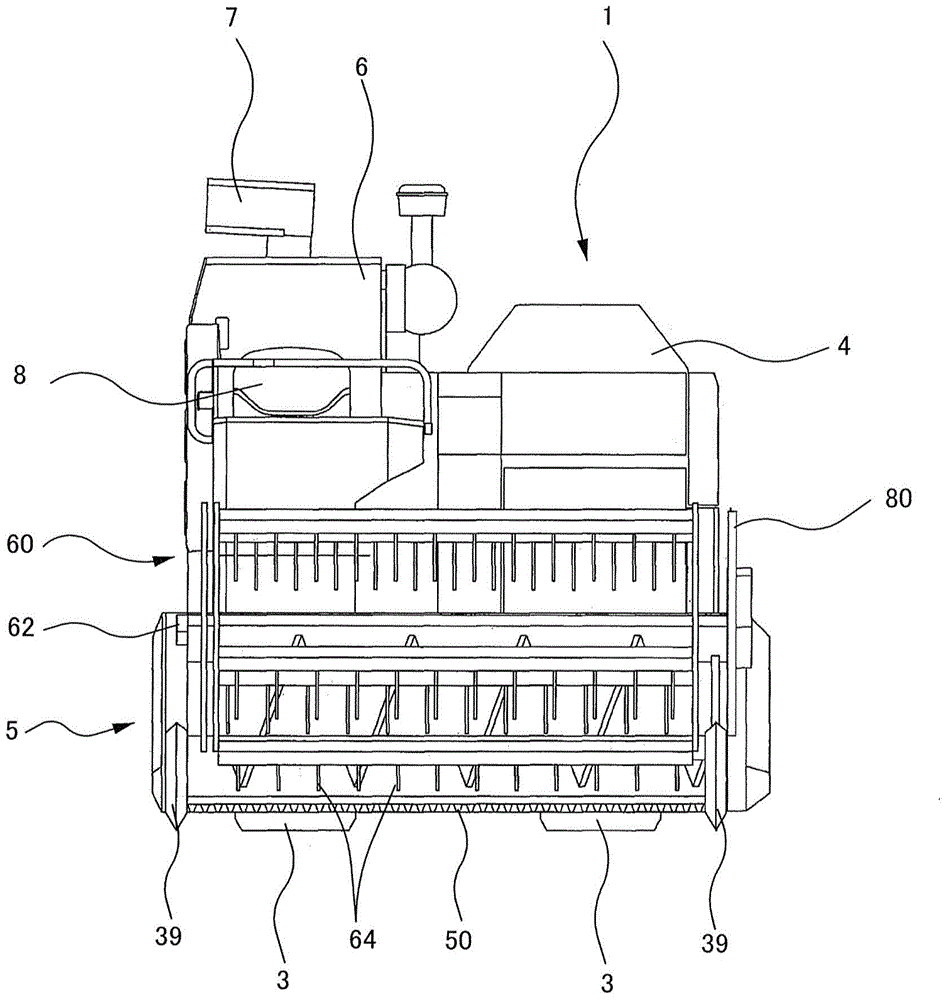

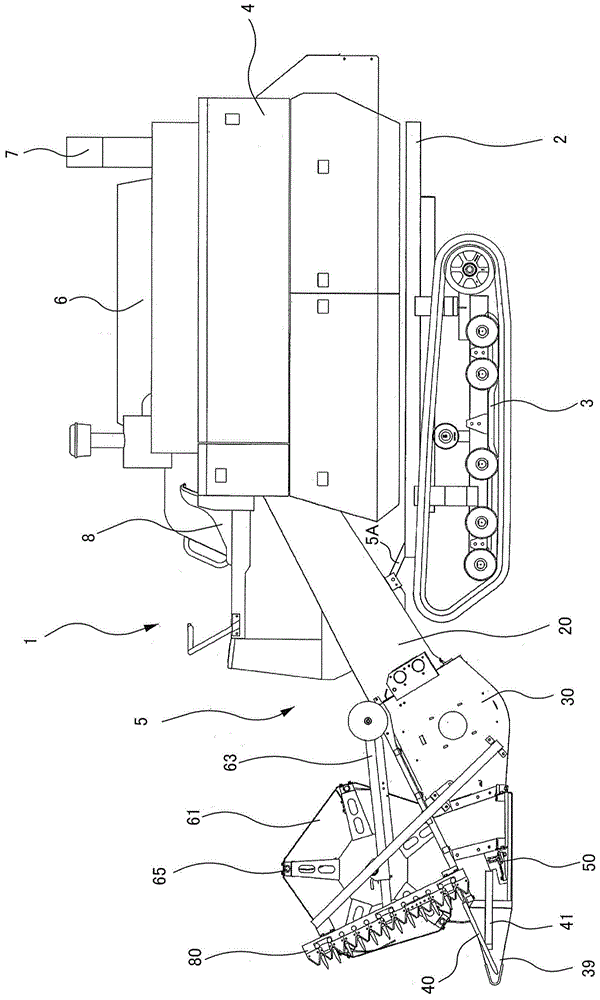

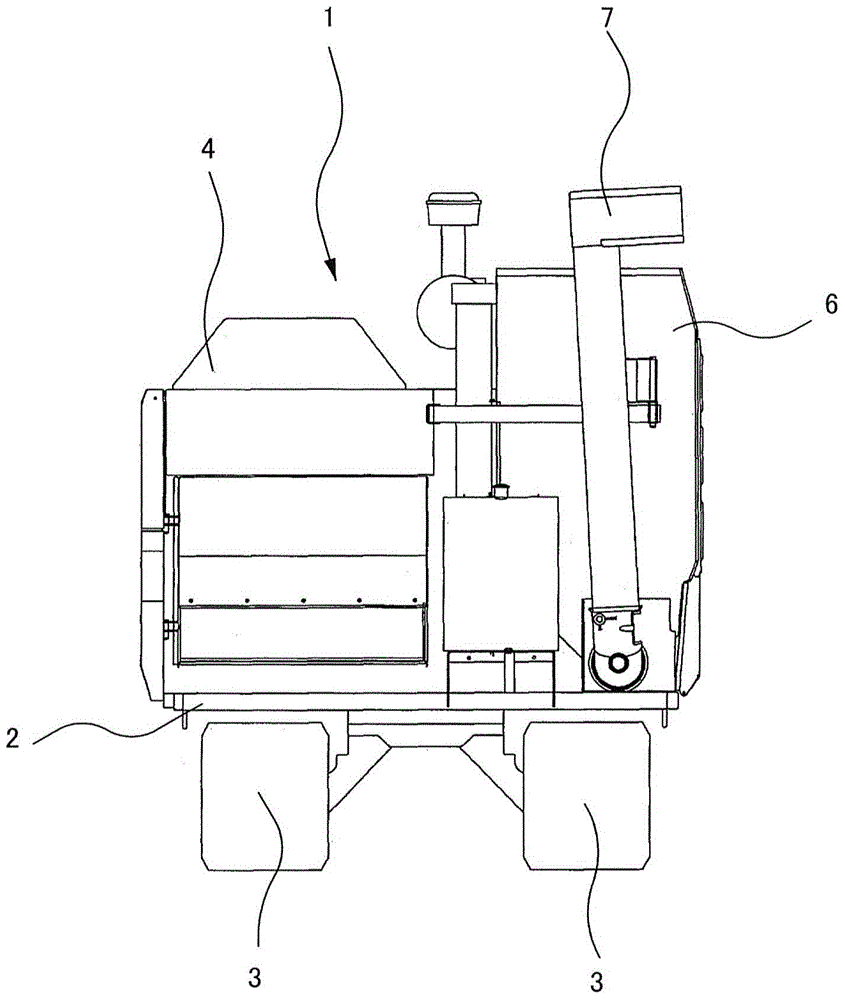

[0052] Hereinafter, the general-purpose combine of this invention is demonstrated referring drawings.

[0053] Universal Combine Harvester 1 AS Figure 1~3 As shown, on the lower side of the body frame 2, for the purpose of driving on the soil surface, a traveling device 3 consisting of a pair of left and right crawler belts is provided, and a threshing device for threshing and screening is provided on the upper side of the body frame 2. 4. On the front side of the threshing device 4, a pre-harvest processing device 5 for harvesting the grain stalks of the farmland is provided. The grain grains threshed and screened by the threshing device 4 are accumulated in the grain container 6 provided on the right side of the threshing device 4, and the accumulated grains are discharged to the outside through the discharge cylinder 7 constituted by the hoisting cylinder and the horizontal conveying cylinder. Moreover, the operation part 8 on which the operator boards is provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com