Shoe tree height fine adjusting mechanism

A fine-tuning mechanism and height technology, applied in shoe lasts, footwear, applications, etc., can solve the problems that the quality of processed shoes is greatly affected, and the mechanism of height adjustment of shoe lasts is not explained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

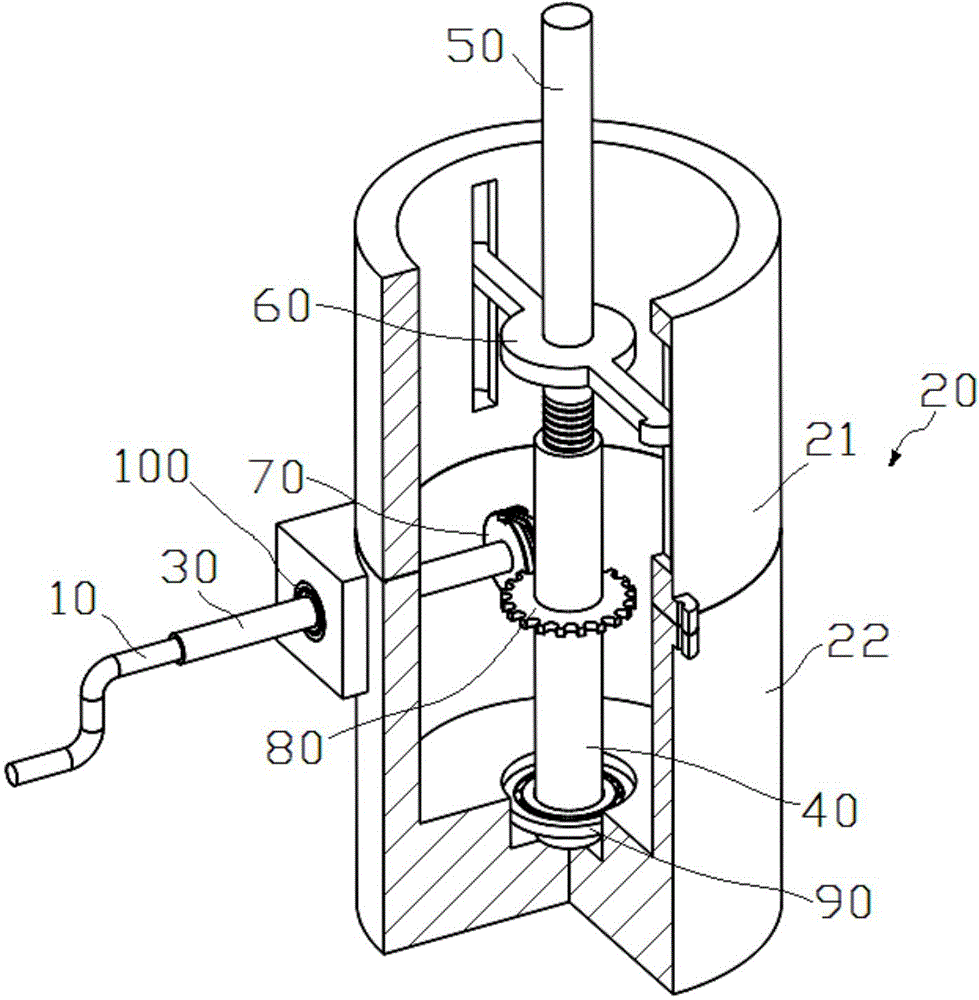

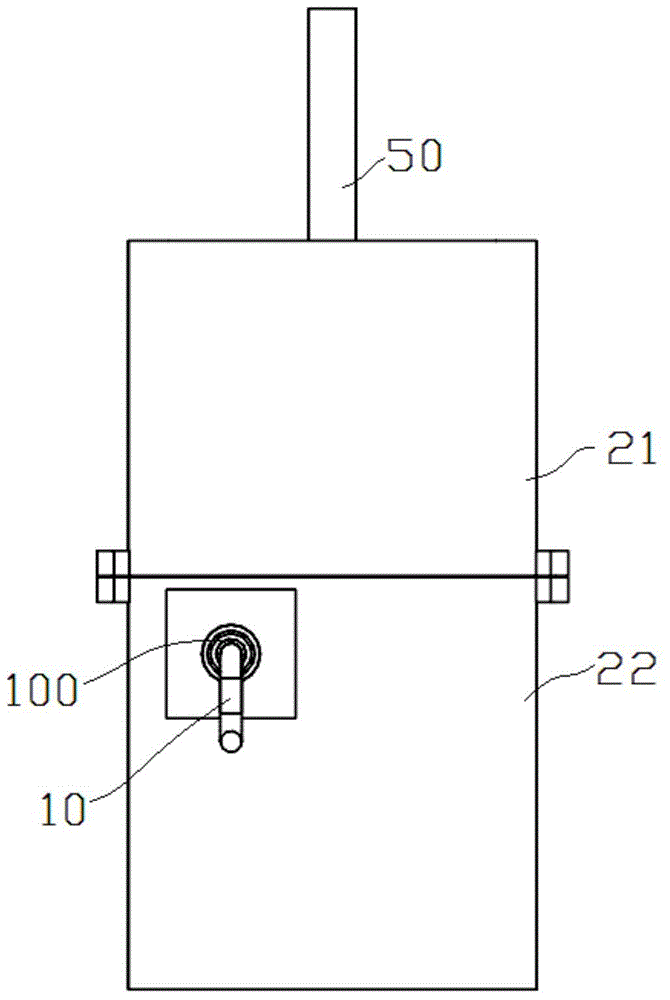

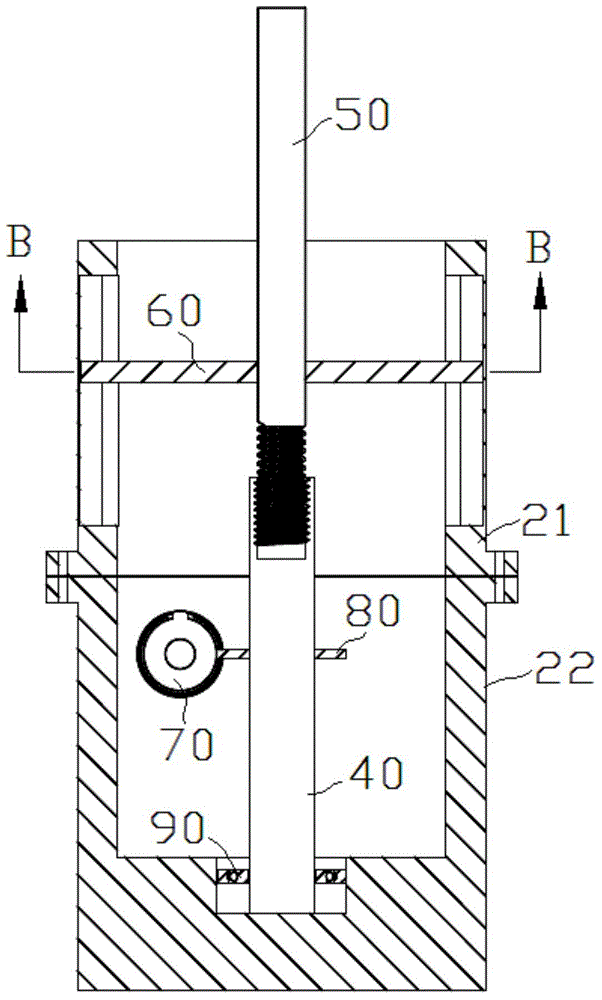

[0022] Such as Figure 1 to Figure 3 , a shoe last height fine-tuning mechanism, including a vertically arranged cylindrical box 20, a rotating shaft 40 is installed in the center of the box 20, and the center line of the rotating shaft 40 coincides with the center line of the box 20; A rotating shaft wheel 80 is installed on the rotating shaft 40, the rotating shaft wheel 80 is a rotating wheel with convex gear teeth 81, the rotating shaft wheel 80 meshes with the driving shaft wheel 70, and the driving shaft wheel 70 is a rotating wheel with a rotating shaft. The rotating wheel of the bit block 71, the center line of the driving shaft wheel 70 is perpendicular to the center line of the rotating shaft wheel 80; the driving shaft wheel 70 is fixed on the driving shaft 30, and the driving shaft 30 passes through the casing 20 and is horizontally arranged. The end of the driving shaft 30 is equipped with a handle 10; the rotating shaft 40 is pivotally connected to the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com