Universal precise plate shearing device

A shearing device and precise technology, applied in metal processing and other directions, can solve problems such as cutting errors, personnel injuries, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

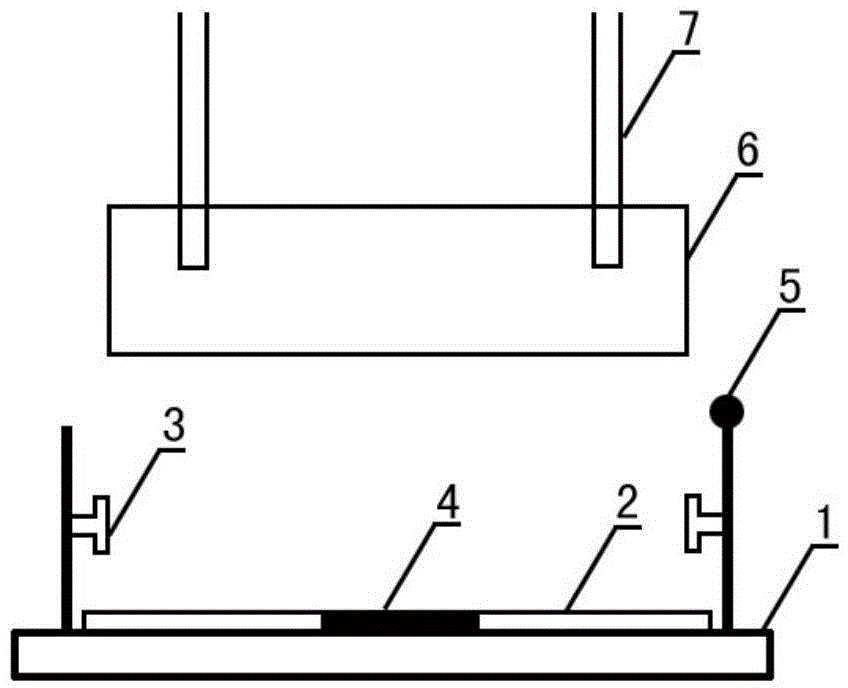

[0012] Embodiment: as shown in the accompanying drawing. A general-purpose precision shearing device, comprising a base (1) with brackets on both sides, a pusher (2) is arranged above the base, capable of pushing wooden boards to corresponding positions for cutting, and fixers (3) are respectively arranged inside the brackets on both sides of the base. ), fix the board so that it does not deviate.

[0013] A universal precision shearing device, in which a control center (4) is arranged in a pusher (2) to control the normal operation of the whole device.

[0014] The utility model relates to a universal precision shearing device. A detection module (5) is arranged on one side of the bracket to accurately measure the cutting position of a wood board and whether the board deviates.

[0015] The utility model relates to a universal precision shearing device, a blade (6) is arranged above a base, and the part is designed to be replaceable.

[0016] The utility model relates to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com