Hydraulic capstan for underground construction field

A hydraulic winch and underground construction technology, applied in the direction of spring mechanism, hoisting device, etc., to achieve the effect of convenient transportation, convenient installation and maintenance, and good airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

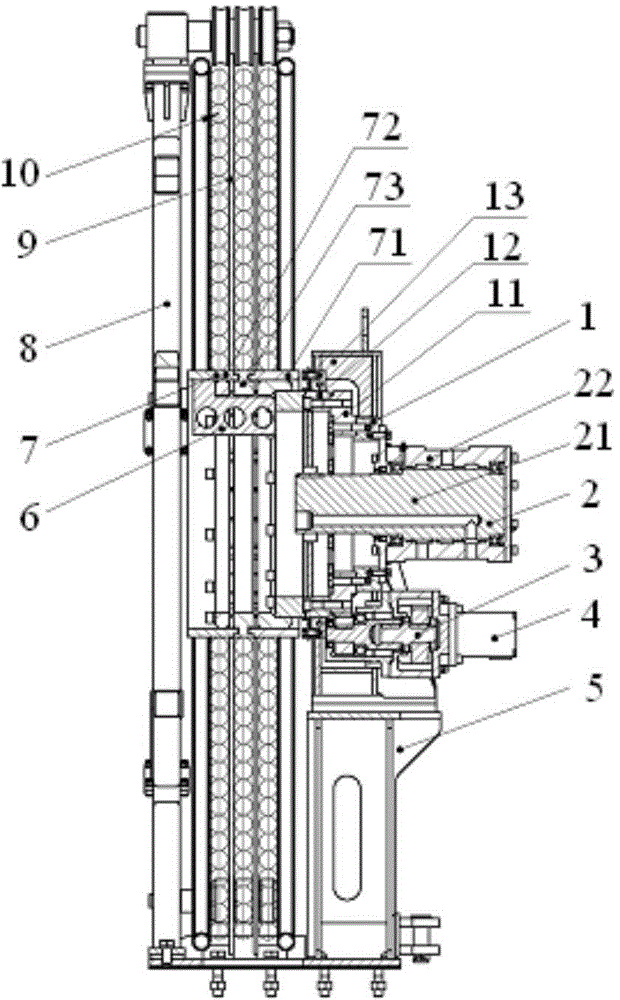

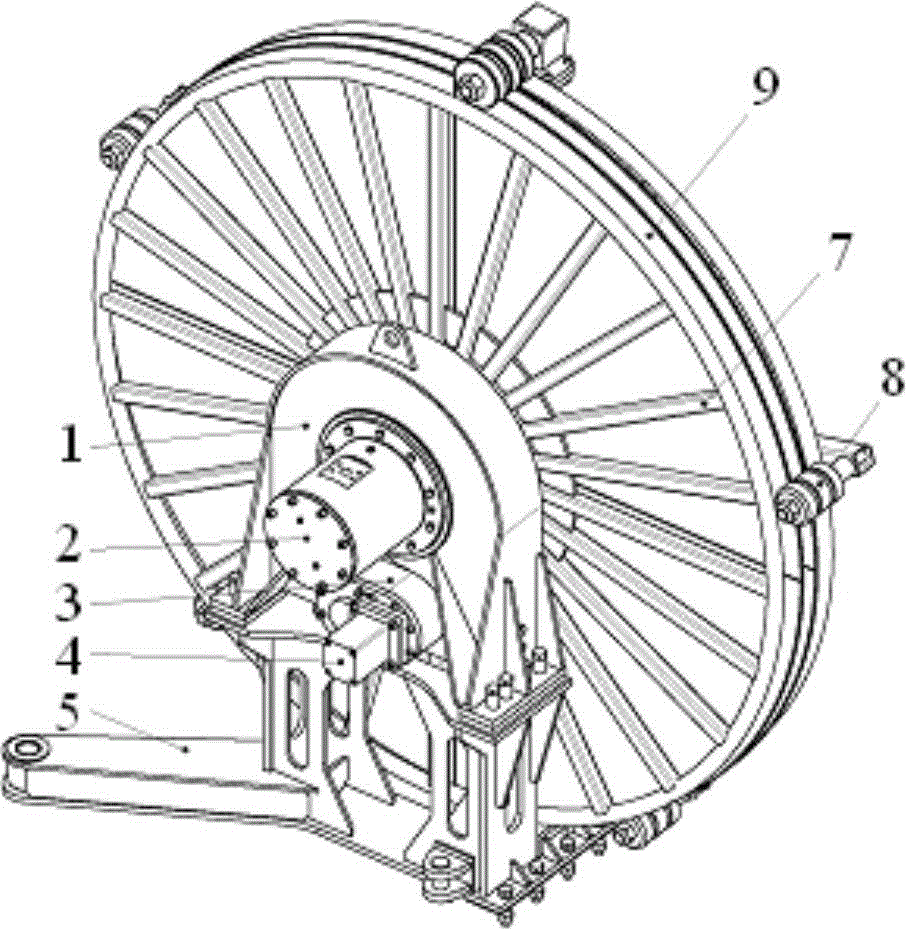

[0028] A hydraulic winch used in the field of underground construction, the structure of which is as follows Figure 1-2 As shown, it includes winch support 1, three-channel rotary joint 2, support base 5, assembled winch 7, reducer 3, hydraulic motor 4, winch guide frame 8 and oil pipe transition plate 6, hydraulic motor 4, reducer 3, three The channel rotary joint 2 and the assembled winch 7 are fixedly installed on the winch support 1, and the winch support 1 is fixed on the support base 5 by bolts, and the assembled winch 7 is provided with a plastic resin partition 9 separating the hydraulic oil pipes 10 , the end of the hydraulic oil pipe 10 is connected on the oil pipe transition plate 6, and the outer side of the assembled winch 7 is provided with a winch guide frame 8.

[0029] The winch support 1 includes a slewing support 11, a transition disc 12 and a box body 13. The reducer 3 engages with the outer ring of the slewing support 11 through the connecting shaft and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com