Forming die group capable of being replaced and mounting plurality of die cores

A technology for forming molds and mold cores, which is applied in the field of mold sets that can be replaced and installed with mold core sets, can solve the problems of space without elastic adjustment, waste of materials, etc., to reduce manpower expenditure, reduce the loss of replacement time, The effect of multi-elastic adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

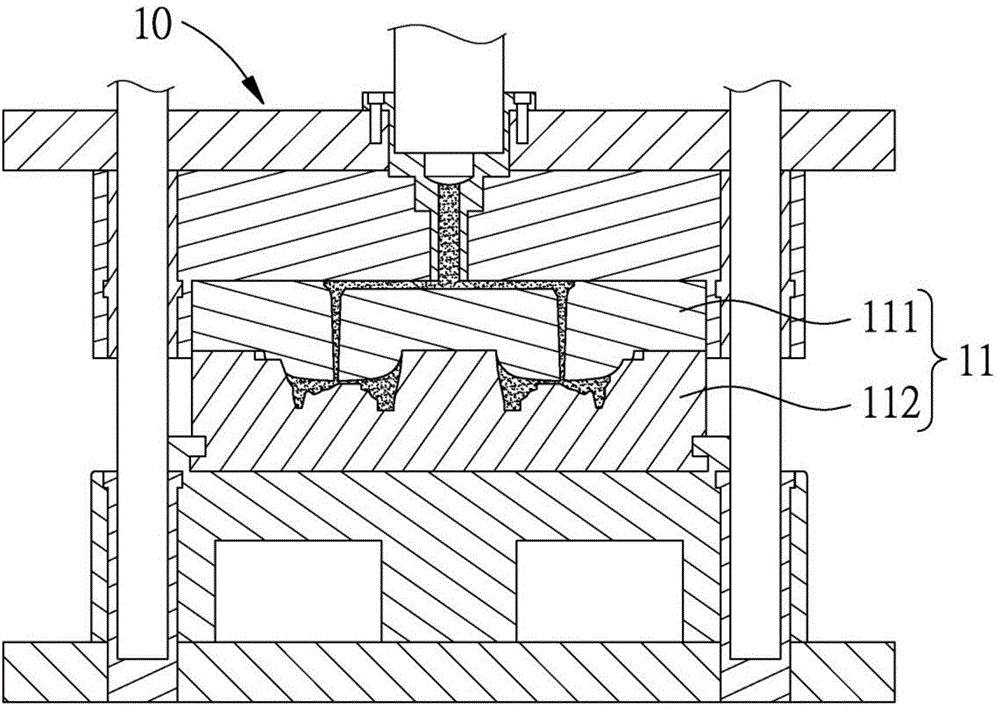

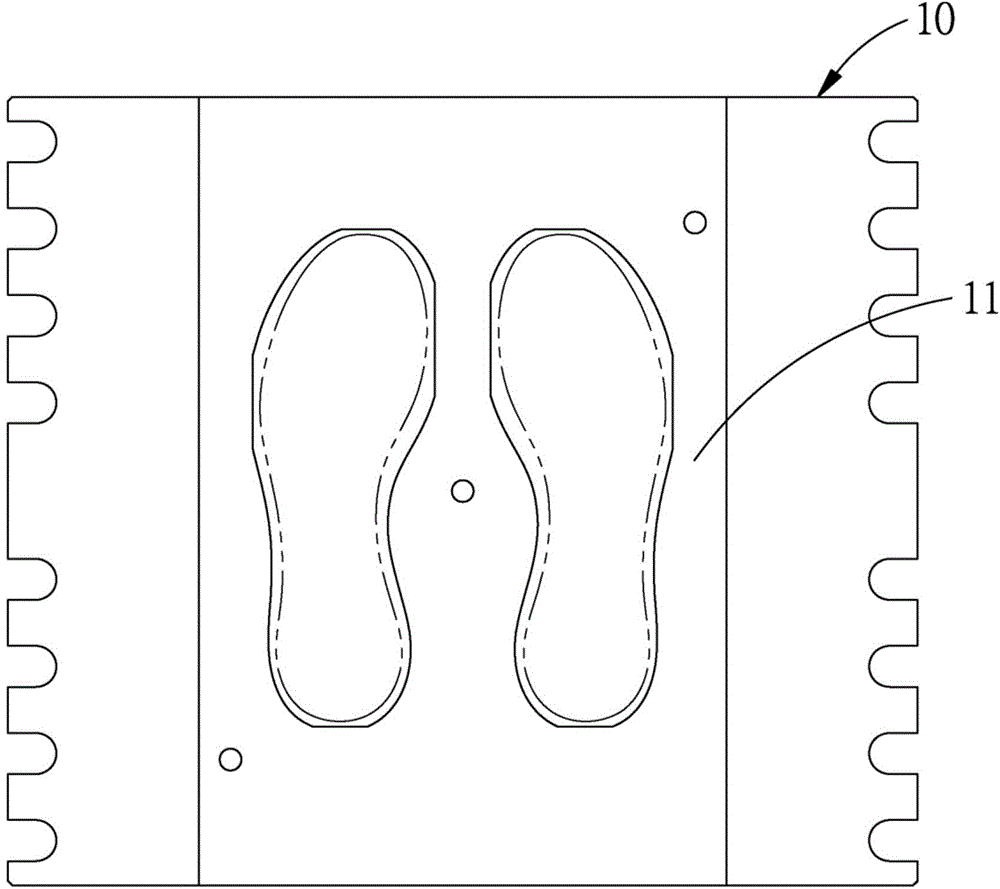

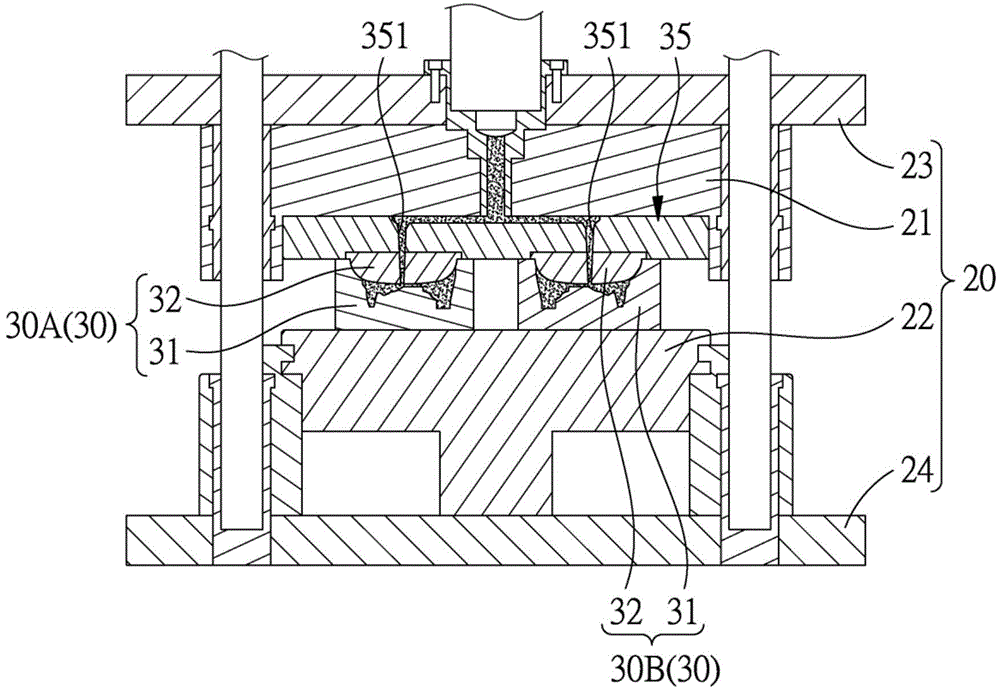

[0031] The present invention can replace the preferred embodiment of the molding die set with multiple mold cores installed, such as Figure 3 to Figure 4 As shown, it includes: a mold body 20 and a plurality of mold core groups 30. In this embodiment, each mold core group 30 is used to make a shoe sole, wherein:

[0032] The mold body 20 includes a first template 21 and a second template 22 correspondingly arranged, and the first template 21 is fixed on a first mounting plate 23, and the second template 22 is fixed on a second mounting plate 24; and

[0033] A plurality of mold core groups 30, each mold core set 30 includes a female mold core 31 and a male mold core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com