liquid storage tank

A liquid storage tank and liquid storage technology, applied in the direction of hydraulic brake transmission device, fluid pressure actuation device, oil supply tank device, etc., can solve the problem of difficult capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

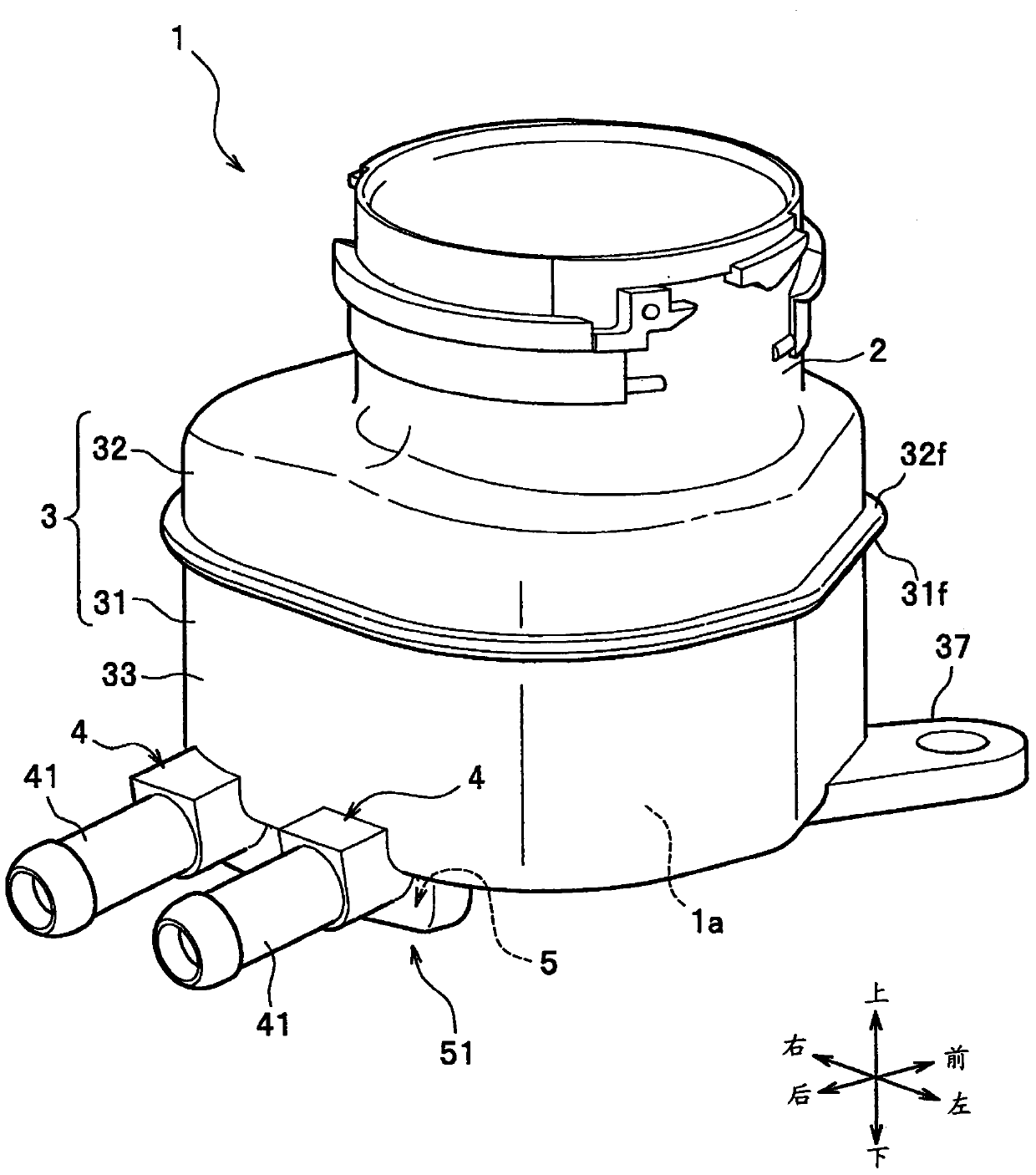

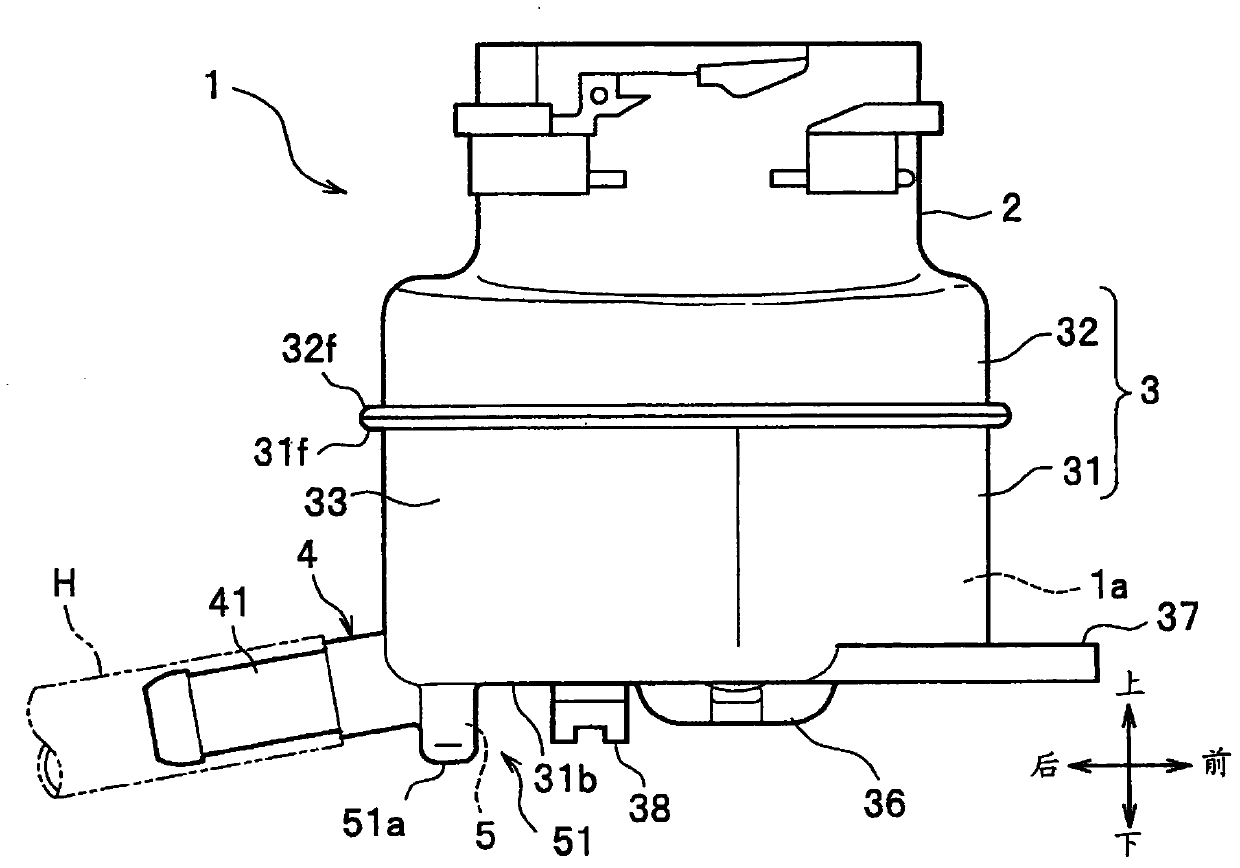

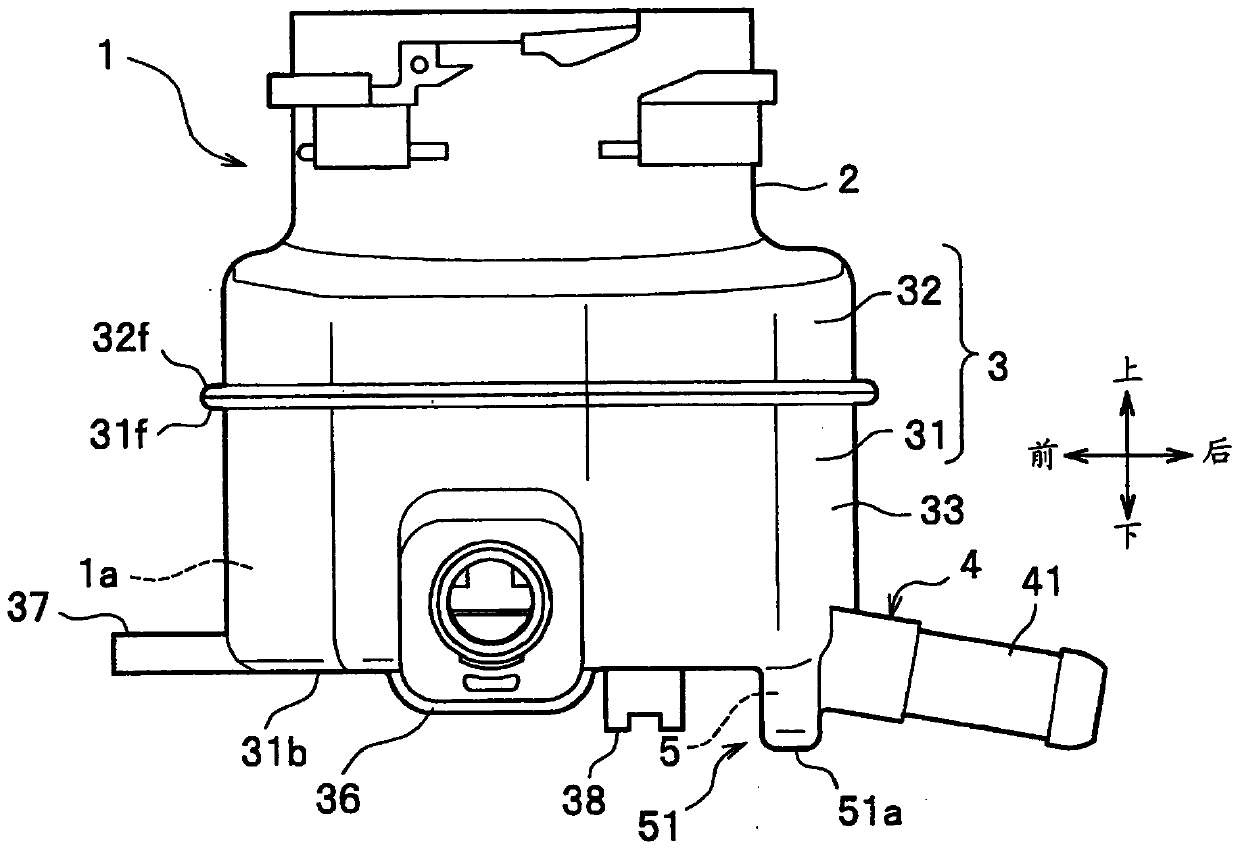

[0049] like figure 1 As shown, the reservoir tank 1 of this embodiment is held by an unillustrated bracket of the vehicle. For example, the bracket is supported by a side wall of the engine room or the like under a hood in the engine room (not shown). In addition, although the reservoir tank connected to the master cylinder device provided in the hydraulic pressure control device was exemplified below, the device to which the reservoir tank is connected is not limited.

[0050] For example, the master cylinder device is attached to the dash panel that divides the engine room and the vehicle interior. The working fluid (brake fluid) stored in the reservoir tank 1 passes through the connecting hose H (refer to figure 2 hereinafter the same) are supplied to the master cylinder device.

[0051] In addition, in the engine room, an engine, a transmission, and the like, which are not shown in the figure, or peripheral devices thereof, or an electric motor instead of the engine, a...

no. 2 approach

[0085] refer to Figure 11 The liquid storage tank 1 of the second embodiment will be described. This embodiment differs from the above-described first embodiment in that a concave portion 60 is provided opposite to the working fluid supply port 4B provided on the bottom wall 31c of the lower half body 31 . In addition, a hose joint portion is integrally provided with the hydraulic fluid supply port 4B.

[0086] like Figure 11 As shown in (a), the concave portion 60 is opened and formed in a cylindrical shape so as to surround the opening portion 4a of the working fluid supply port 4B provided on the bottom surface 31a in plan view. On the inner peripheral surface 2a ( Figure 11 In (a) shown by a two-dot chain line) projected onto the bottom surface 31a, the concave portion 60 is arranged between the working fluid inlet 2 (inner peripheral surface 2a) and the working fluid supply port 4B (opening 4a). Formed space S1.

[0087] like Figure 11 As shown in (b), the conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com