Exhaust gas treatment device

A waste gas treatment device and technology for waste gas, which are applied in combination devices, lighting and heating equipment, and dispersed particle separation, etc., can solve the problems of mesh blockage, wire mesh damage, and abrasion of wire mesh, and achieve the effect of damage suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] figure 1 is a schematic configuration diagram showing a pulverized coal incineration boiler to which the exhaust gas treatment device according to Example 1 of the present invention is applied, figure 2 is a schematic side view showing the exhaust gas treatment device of Example 1, image 3 It is a schematic plan view showing the exhaust gas treatment device of Example 1.

[0072] The pulverized coal incineration boiler to which the exhaust gas treatment device of Example 1 is applied is a boiler that can use pulverized coal after pulverizing coal as a solid fuel, burn the pulverized coal with a combustion furnace, and treat Heat is recovered.

[0073] In this embodiment 1, if figure 1 As shown, the pulverized coal incineration boiler 10 is a traditional boiler with a furnace 11 and a combustion device 12 . The melting furnace 11 has a square tube hollow shape and is installed along the vertical direction, and a combustion device 12 is provided at a lower portion o...

Embodiment 2

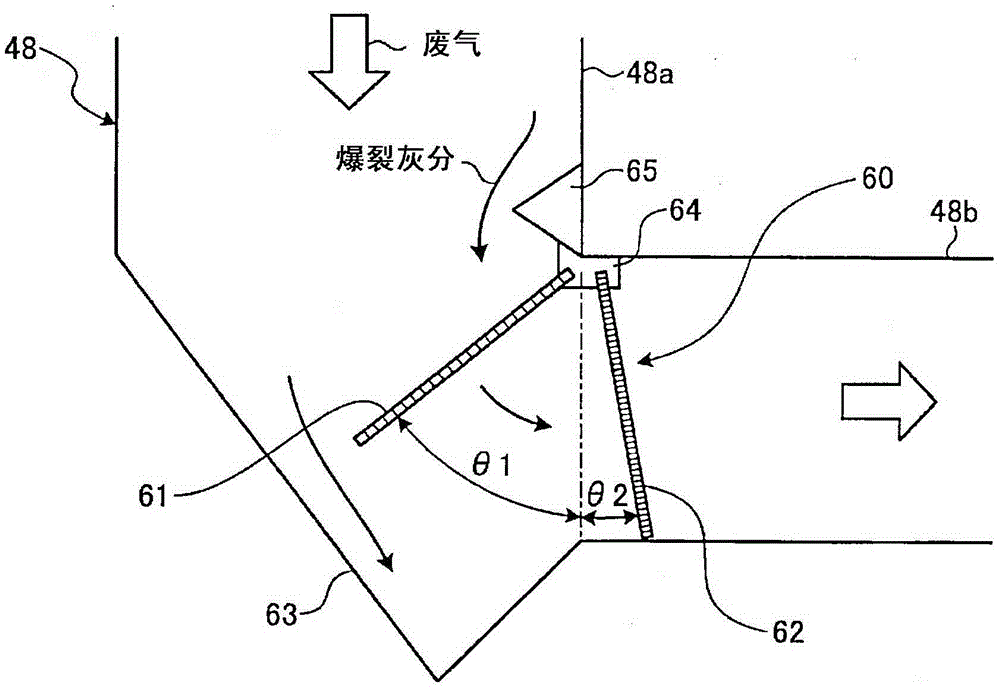

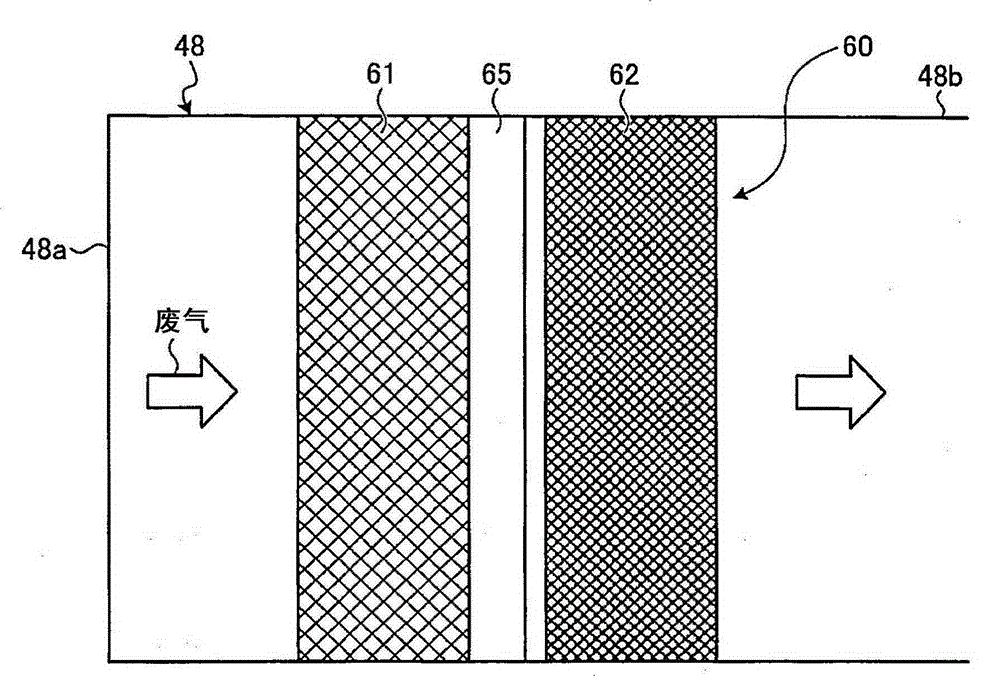

[0104] Figure 4 It is a schematic diagram showing the exhaust gas treatment device according to the second embodiment of the present invention. It should be noted that members having the same functions as those in the above-mentioned embodiments are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0105] In the exhaust gas treatment device of embodiment 2, such as Figure 4As shown, an explosion ash collection part 60 capable of collecting the explosion ash in the exhaust gas is provided between the heat recovery part and the harmful substance removal part in the exhaust gas pipe 48. The explosion ash collection part 60 includes: The first trapping portion 61 with a low aperture ratio; the second trapping portion 62 with a low aperture ratio.

[0106] The exhaust gas pipe 48 is constituted by a first pipe 48a extending in the vertical direction and a second pipe 48b extending in the horizontal direction communicating in directions ...

Embodiment 3

[0116] Figure 5 It is a schematic diagram showing the exhaust gas treatment device according to the third embodiment of the present invention. It should be noted that members having the same functions as those in the above-mentioned embodiments are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0117] In the exhaust gas treatment device of embodiment 3, such as Figure 5 As shown, an explosion ash collection part 60 capable of collecting the explosion ash in the exhaust gas is provided between the heat recovery part and the harmful substance removal part in the exhaust gas pipe 48. The explosion ash collection part 60 includes: The first trapping portion 61 with a low aperture ratio; the second trapping portion 62 with a low aperture ratio. The upper end portion of the first collecting portion 61 is fixed to a bracket 64 fixed inside the corner of the communication portion between the first pipe 48a and the second pipe 48b, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com