Automatic speed-changing device

A technology of automatic transmission and drive mechanism, applied in chain/belt transmission, vehicle gearbox, transportation and packaging, etc., can solve problems such as accelerated wear of chains and gear discs, uneven shifting, and derailleurs working together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

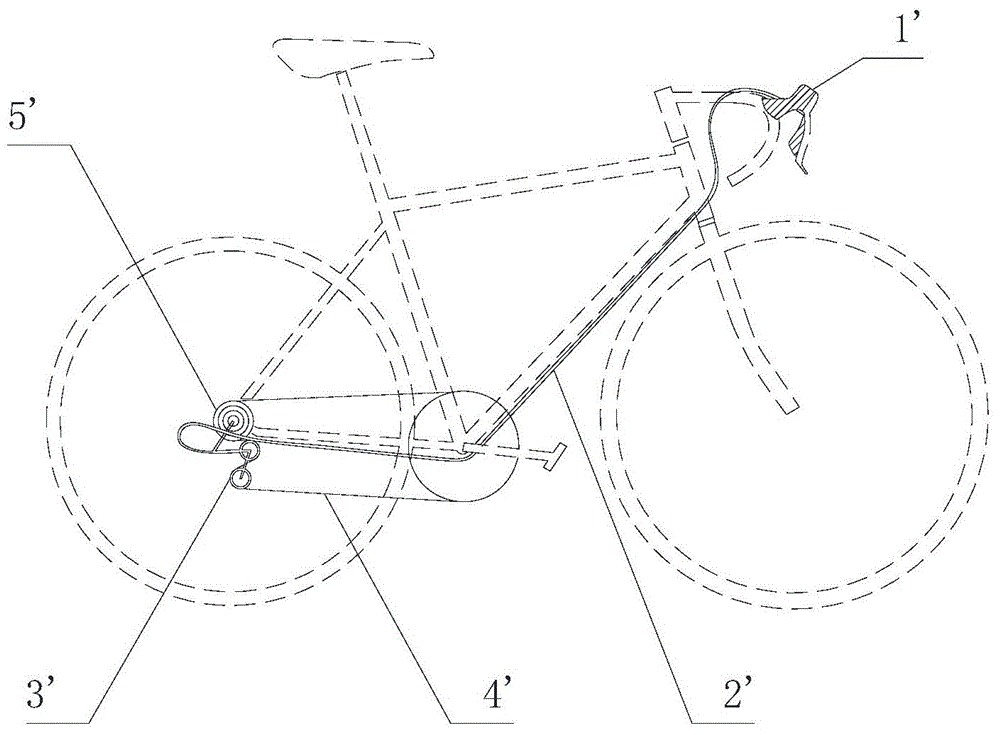

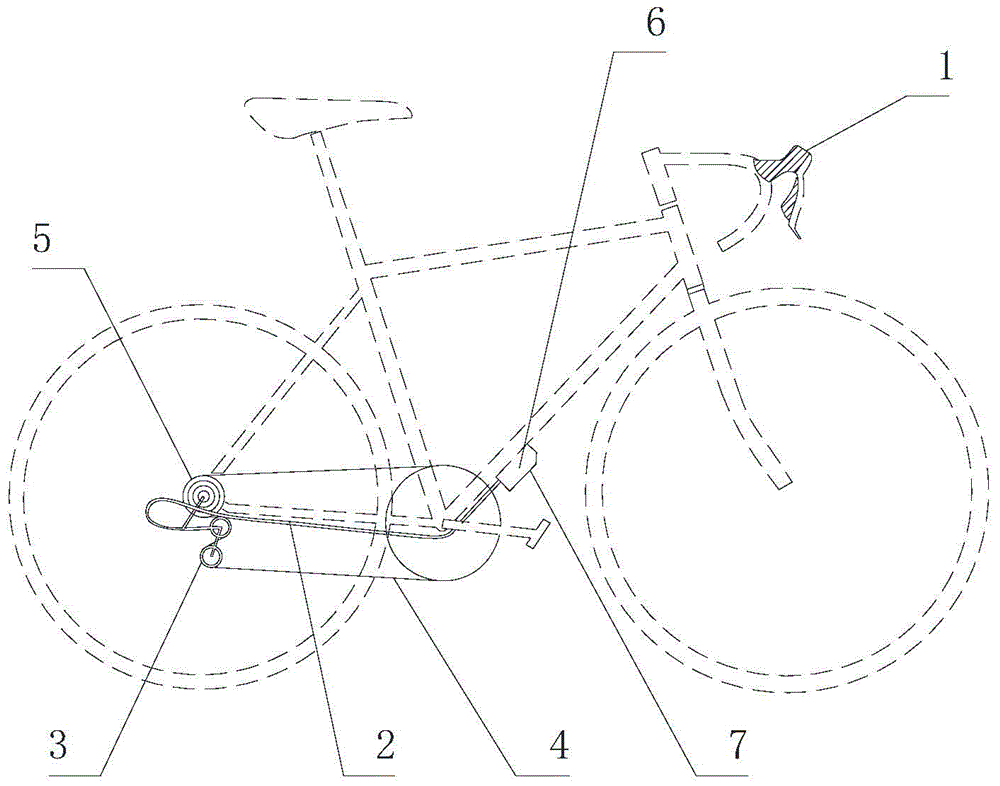

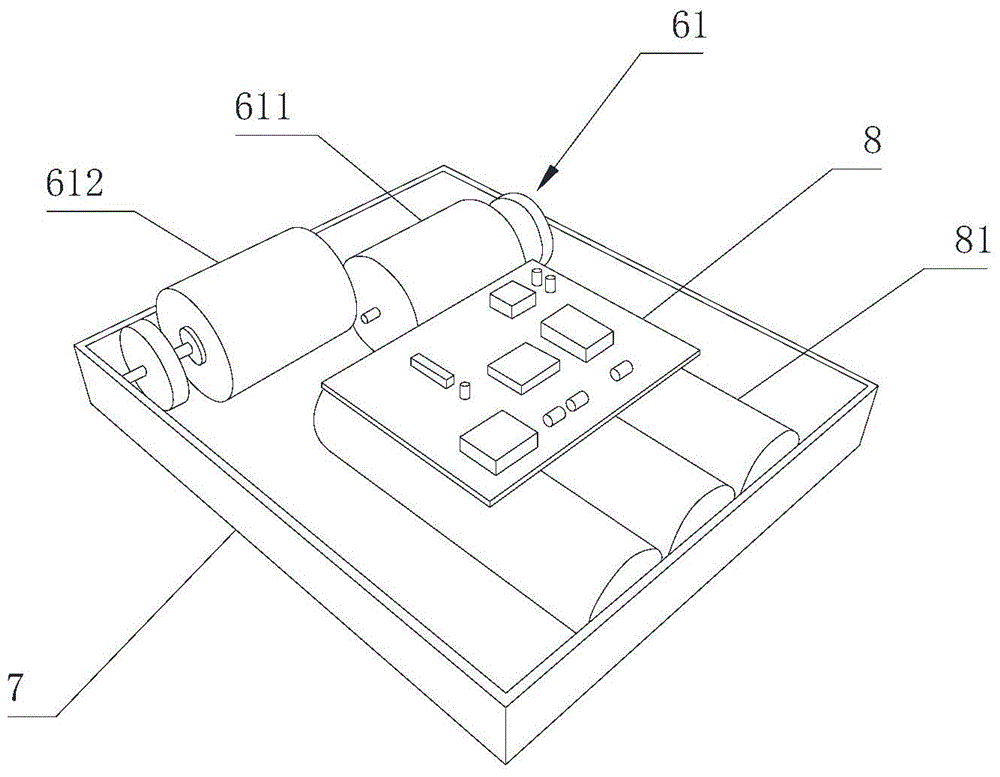

[0047] see Figure 2-Figure 4 As shown, the present embodiment provides an automatic transmission. figure 2 Schematic diagram of the structure of the automatic transmission device provided in this embodiment; image 3 It is a structural schematic diagram of the box body of the automatic transmission device, where the upper cover is not shown; Figure 4 is the schematic diagram of the automatic transmission device; in order to show the structure more clearly, figure 1 , figure 2 The parts of the bicycle such as the wheels and frame shown are represented by dotted lines, and the hatching shown in the figure is not to express the hatching, but to show the shifting handle more clearly.

[0048] see Figure 2-Figure 4As shown, the automatic transmission device provided in this embodiment includes a cable 2 and a derailleur 3, and also includes a driving mechanism 6, a sensor 9 and a controller 8;

[0049] One end of the pull wire 2 is connected to the output end of the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com