A high-precision and high-reliability all-fiber optic current transformer

A current transformer, all-fiber technology, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of light emission wavelength changing with temperature, poor measurement accuracy of small current, and unstable output power, etc. The effect of preventing system failure, stable output optical power, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] The high-precision and high-reliability all-fiber-optic current transformer described in the present invention is based on the Ampere loop law and the magneto-optic Faraday effect for current measurement. The magnitude of the phase difference to indirectly measure the current value.

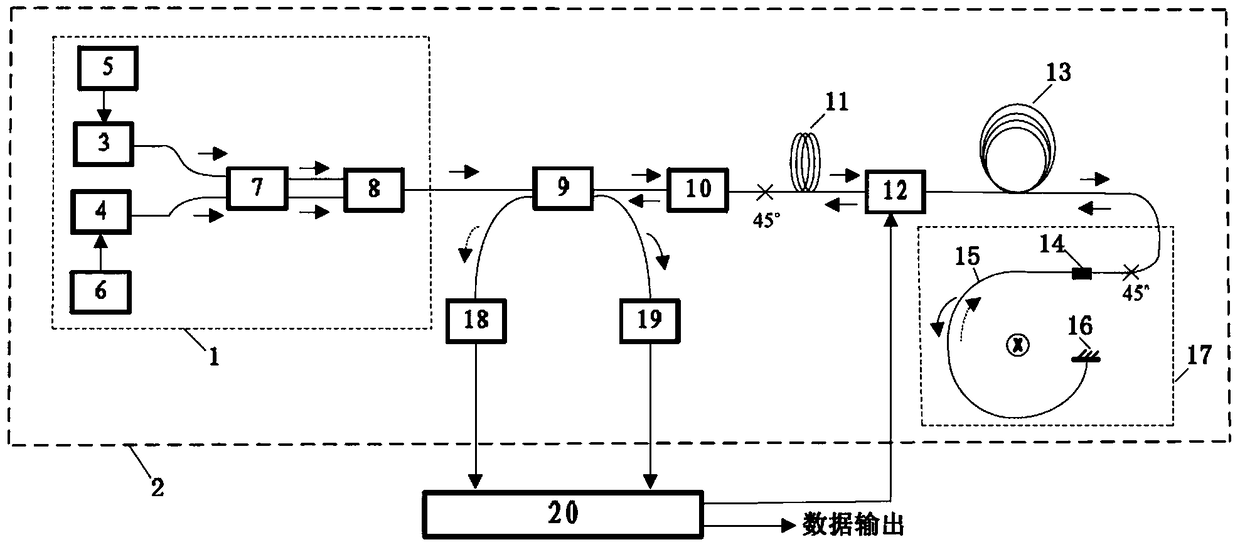

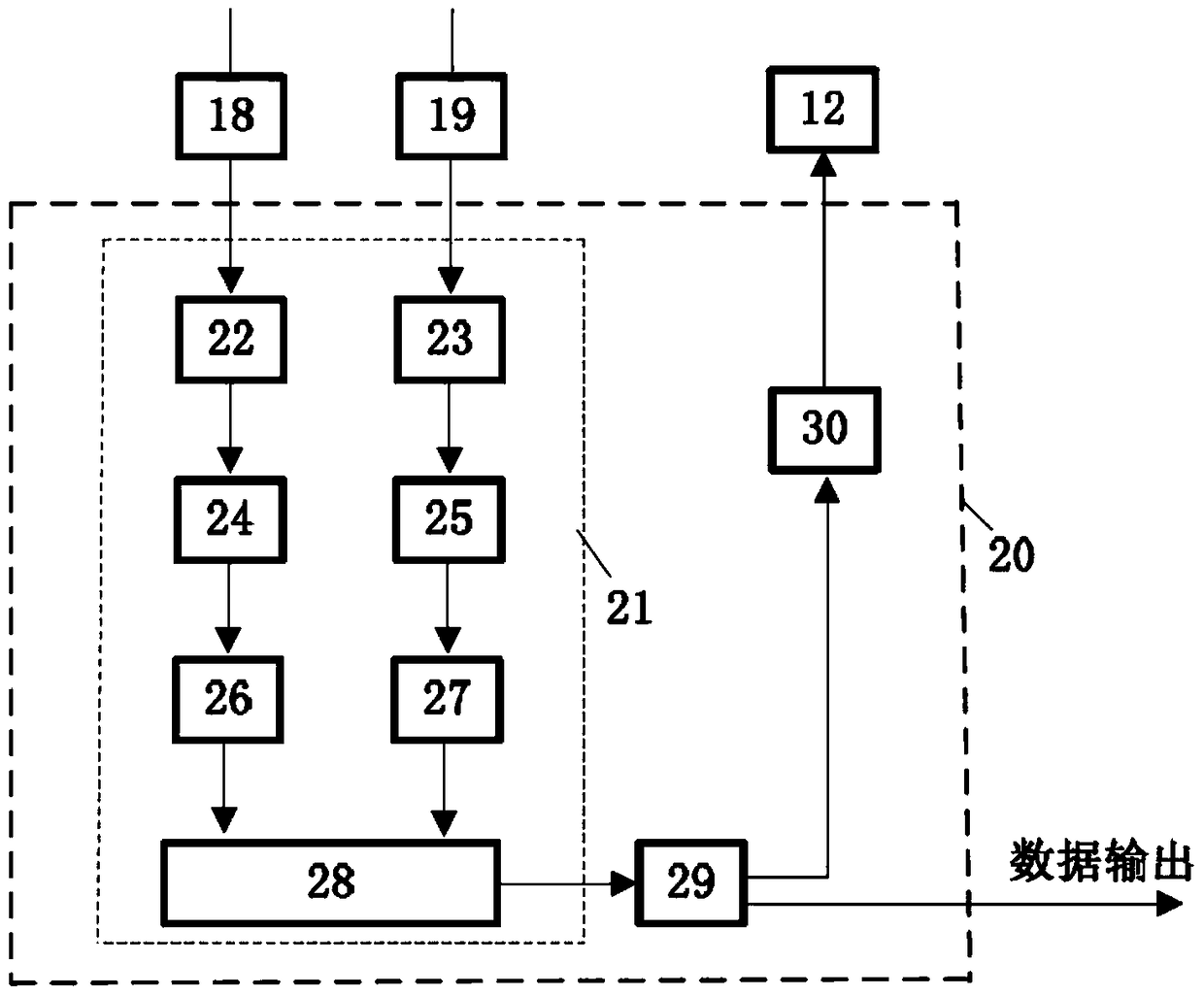

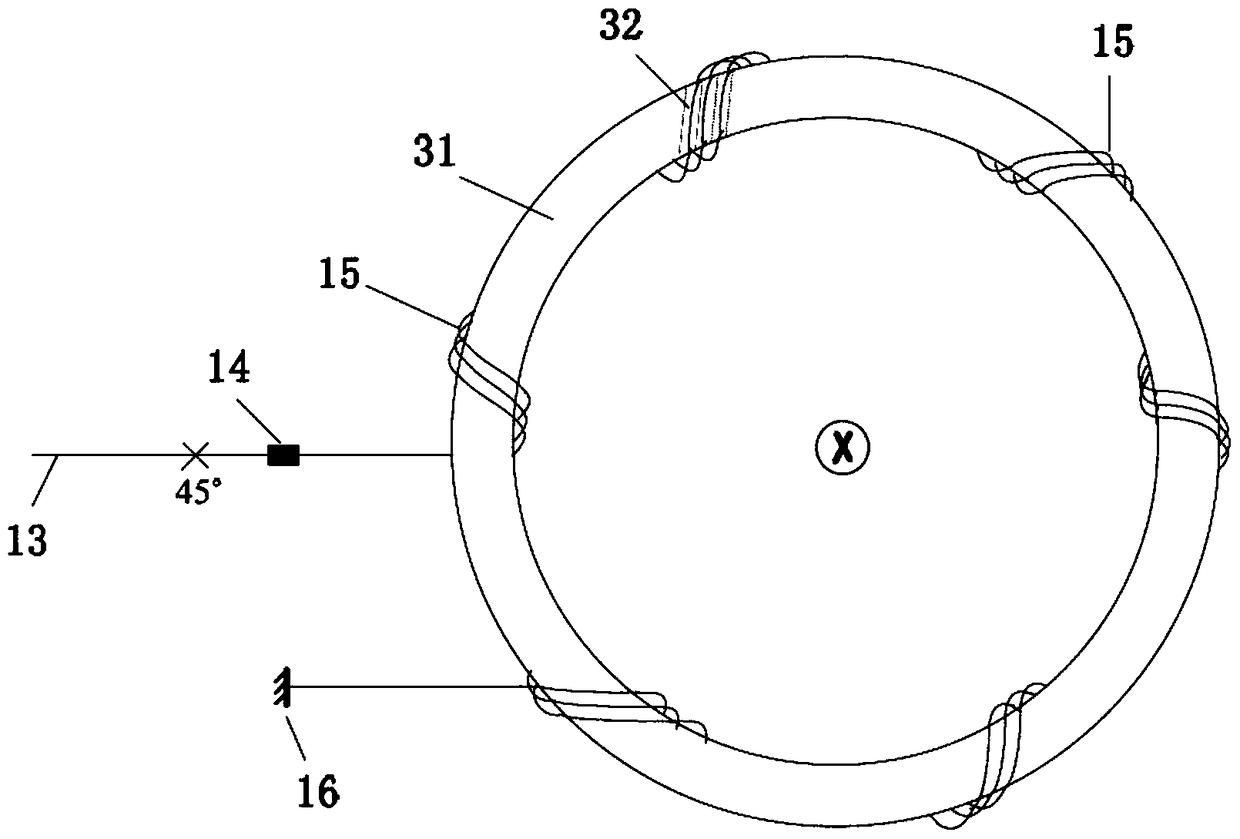

[0030] like figure 1 As shown, the present invention is composed of an optical system unit 2 and a digital signal processing unit 20 . The light emitted by the light source unit 1 in the optical system unit 2 passes through the first single-mode coupler 7 with a splitting ratio of 50:50, and one beam of light passes through the polarizer 10 and is then divided into two orthogonal linearly polarized beams , two beams of orthogonal linearly polarized light are injected into the fast and slow axes of the polarization-maintaining fiber through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com