A liquid-liquid extraction system and process for use thereof

An extraction and process technology, applied in the field of liquid-liquid extraction systems, which can solve the problems of complex machines, expensive investment and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

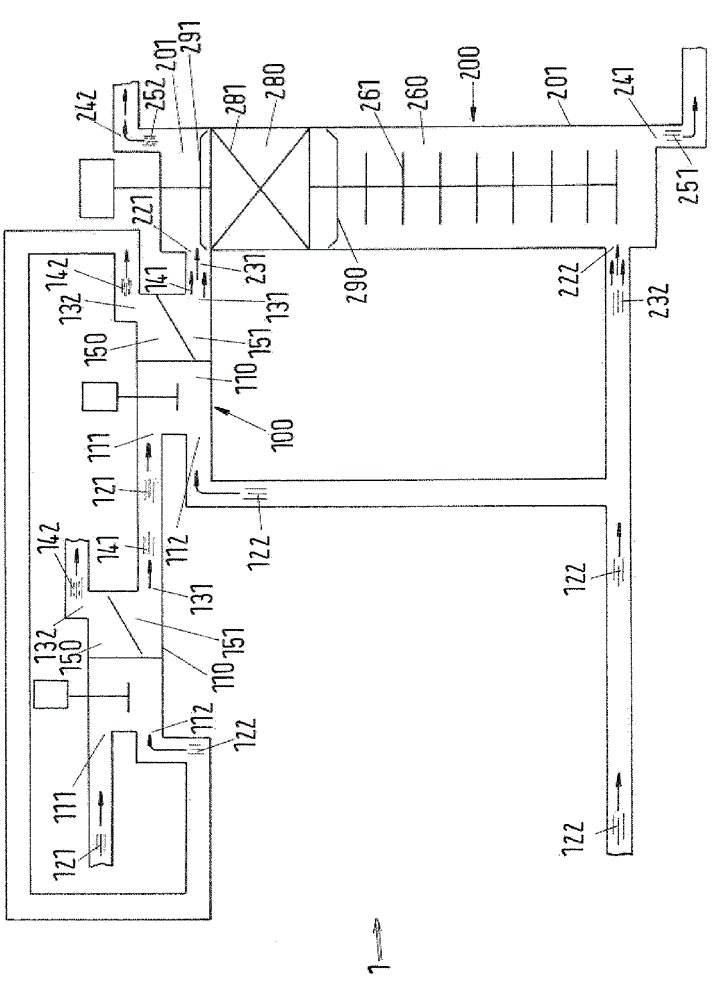

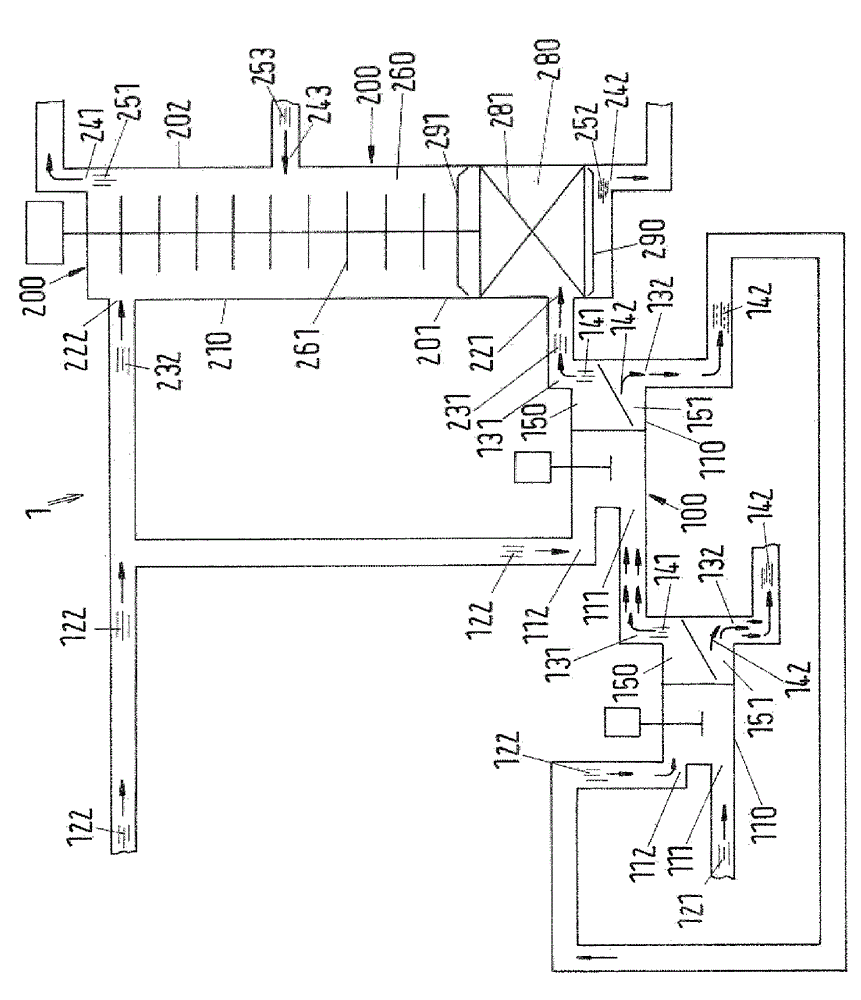

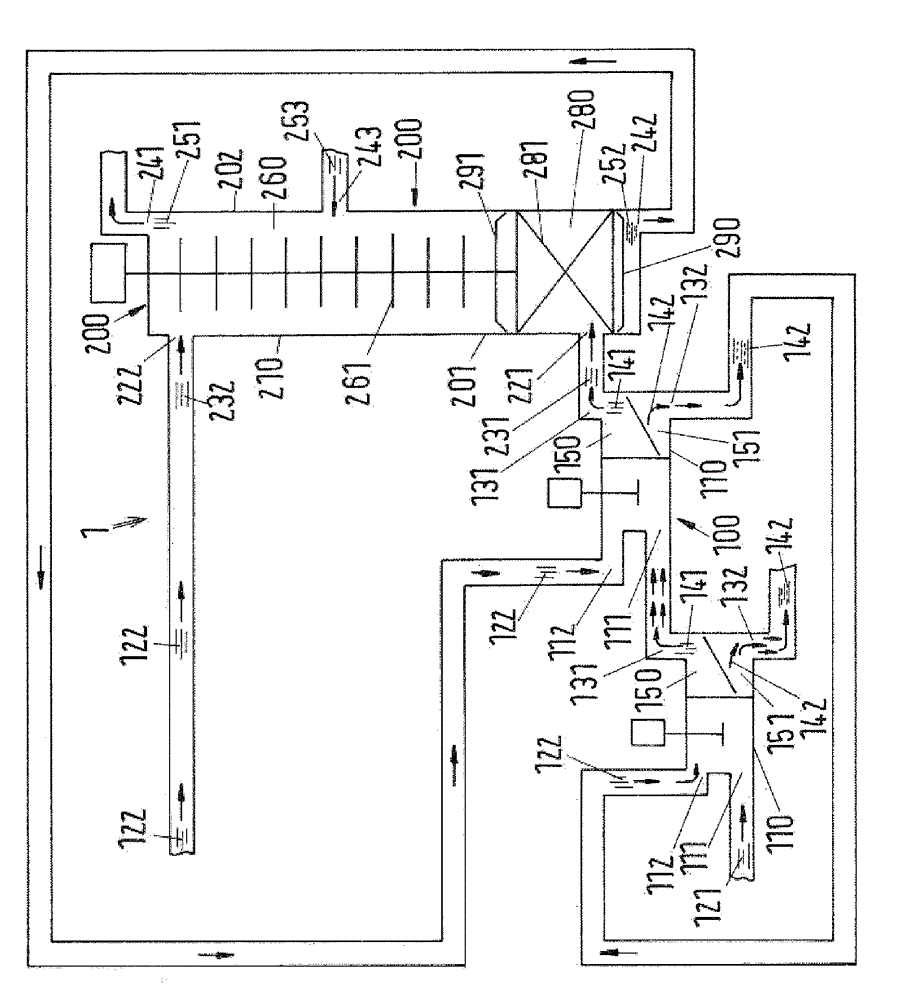

[0049] figure 1 A schematic view of an embodiment of a liquid-liquid extraction system according to the invention is shown, which is designated as a whole with the reference number 1 . The extraction system 1 is not particularly limited as to form, shape, configuration or composition unless otherwise specified. Any material that can be used for fabrication can be supported by the extraction system 1 . For reasons of economy, the extractor may typically be made of FRP fiberglass reinforced plastic, stainless steel, Alloy 20, or any other material specified for a particular application. Depending on process requirements, the extraction system internals can be made of polypropylene or other plastics with low initial cost or any other material including metal. In one embodiment, the extraction system 1 and its components are constructed of metal, plastic, glass or mixtures thereof. Suitable metals include carbon steel, stainless steel, nickel alloys, copper alloys, titanium and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com