Interface and fluid-transfer system

一种流体传送、传送装置的技术,应用在仪器、机械设备、取样装置等方向,能够解决需要冲洗步骤、给定过程增加成本和复杂性、不期望停滞容积等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] A description of example embodiments of the invention follows.

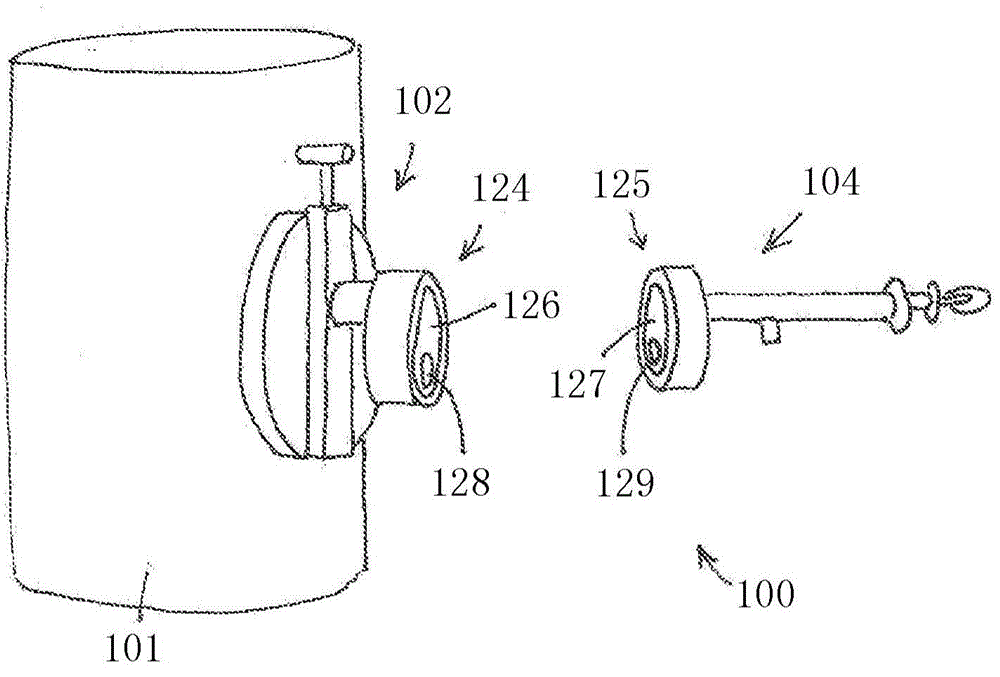

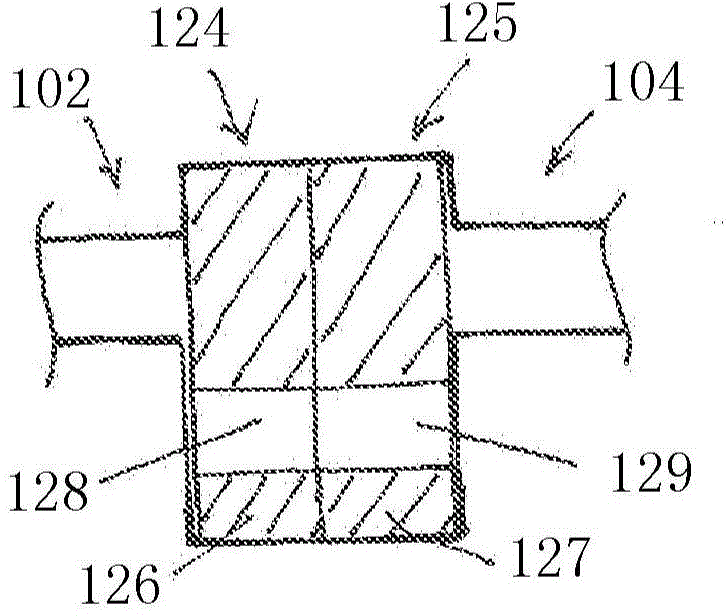

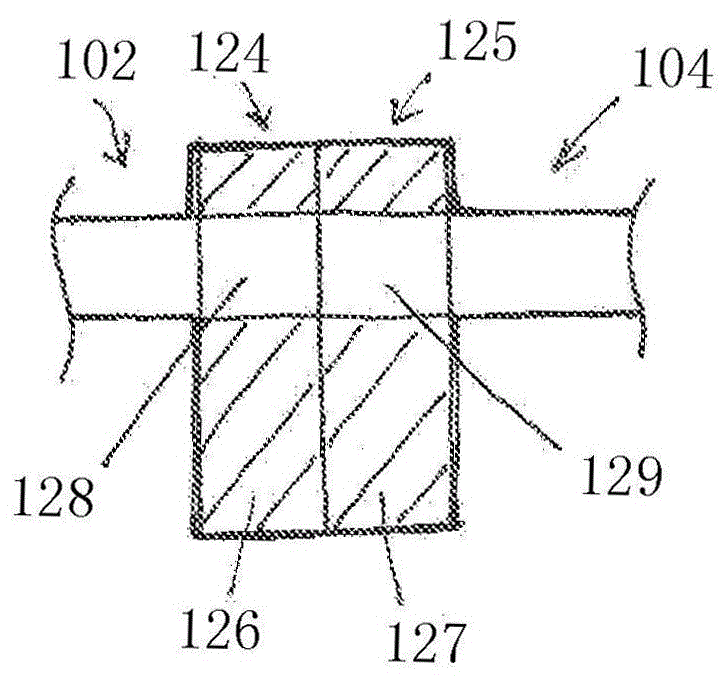

[0090] Figure 1A is a schematic diagram of an example fluid delivery system 100 according to one embodiment of the invention. Fluid delivery system 100 includes an interface device 102 to be mounted to a reservoir 101 and a delivery device 104 to be selectively coupled to interface device 102 . The interface device 102 includes a coupling member 124 including a sliding element 126 having an opening 128 . The transfer device 104 comprises a coupling element or member 125 comprising a sliding element 127 having an opening 129 . exist Figure 1A In , the interface device 102 and the transfer device 104 are shown uncoupled. Coupling members 124 and 125 are in their respective closed positions, opening 128 is out of alignment with interface device 102 , and opening 129 is out of alignment with delivery device 104 . The transfer coupling member 125 is configured to couple to the interface coupling member 124...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com