Feed mechanism for cigarette maker

A knife-feeding mechanism and technology of cigarette making machines, which are applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve problems such as damage to the knife-feeding mechanism, 607 deep groove ball bearing damage, etc., so as to prolong service life, reduce impact load, and be easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

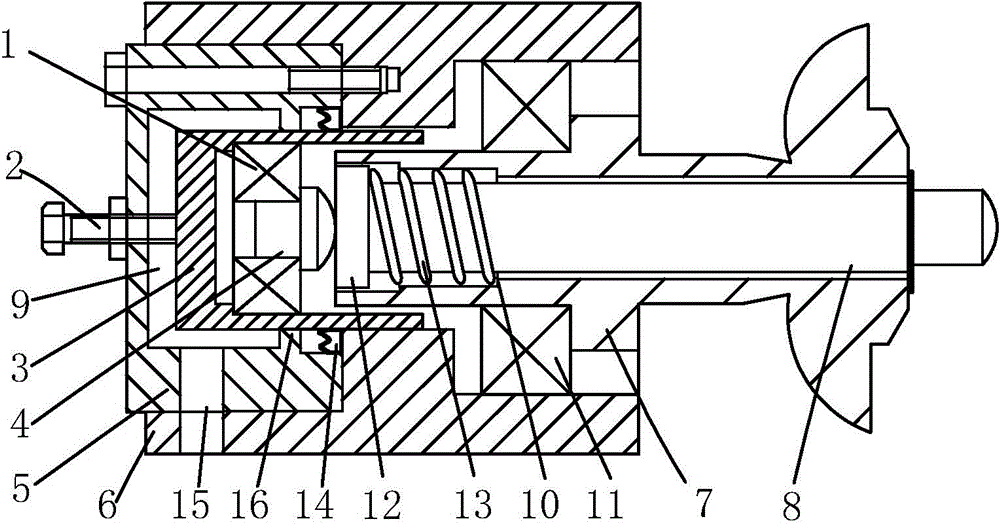

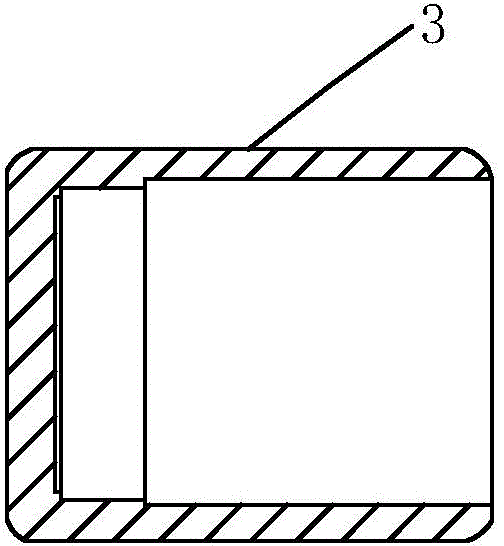

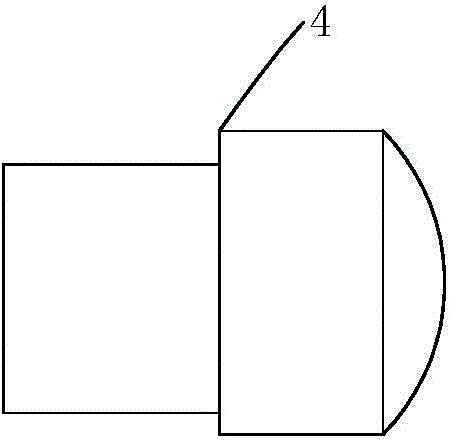

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as Figure 1-3 A cigarette machine feed mechanism shown in , including feed push rod 8, half shaft 7, support 6, air cavity body 5, transmission shaft 4, push rod sleeve 3, transmission shaft bearing 1, limit bolt 2 , the semi-axis 7 is mounted on the support 6 through the bearing, and the semi-axis 7 rotates with the cutterhead at a high speed during operation, and supports the cantilevered cutterhead, and the through hole of the semi-axis 7 is equipped with a feed push rod 8. An air chamber 5 is installed in the support 6, and a push rod sleeve 3 is sealed and embedded in the air chamber 5, and a transmission shaft 4 is installed in the push rod sleeve 3 through the transmission shaft bearing 1. The push rod sleeve 3, transmission The centerlines of the shaft and the semi-axis coincide with the centerline of the feed push rod. When the cutting edge of the cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com