Preheat the air medium to start the mvr evaporation system

An evaporation system and air medium technology, applied in the field of energy-saving technology, can solve the problems of complex system composition and increased equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

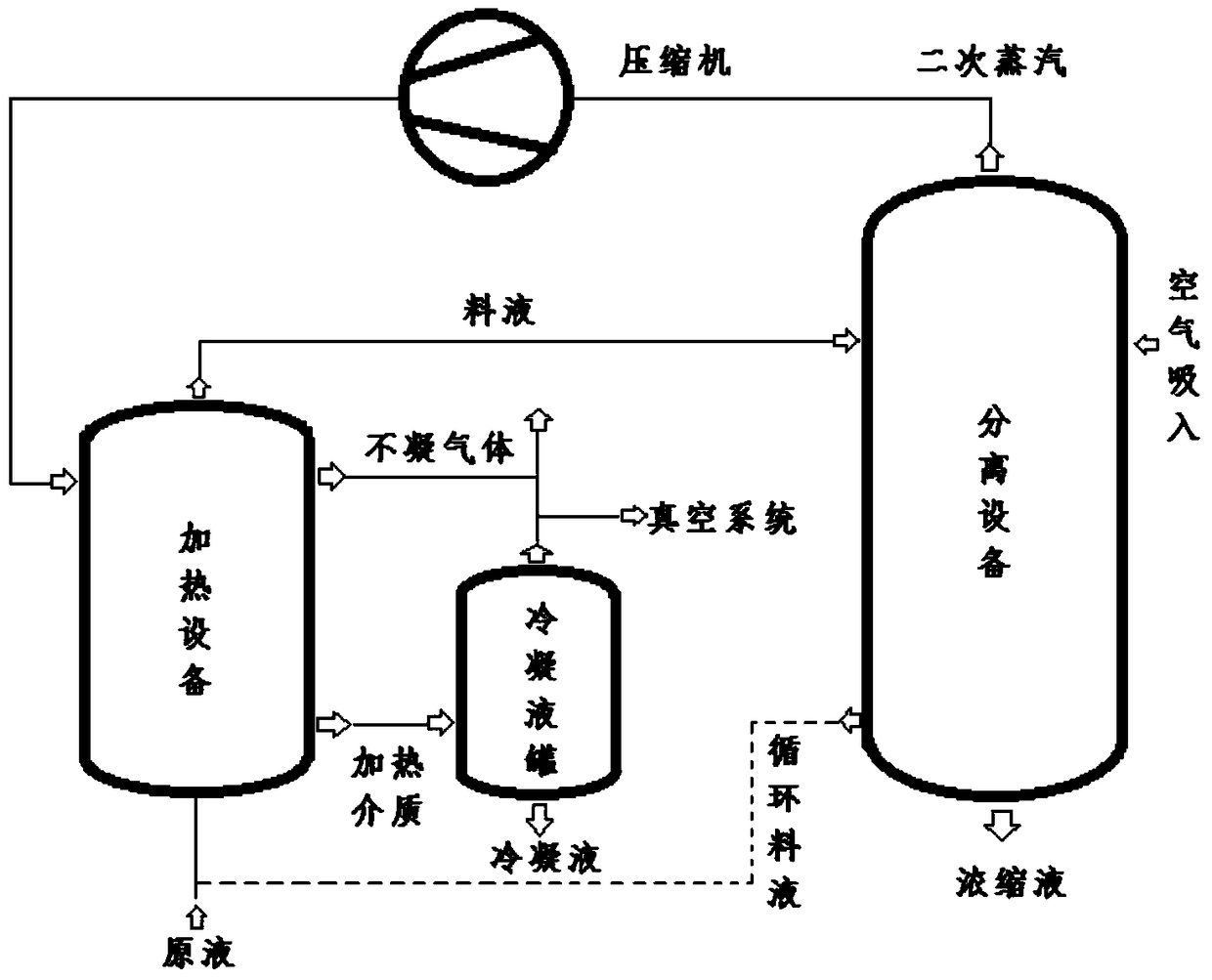

[0007] The important steps and main points of the start-up operation of the MVR evaporation system of the present invention are described as follows:

[0008] 1. Prepare to start the operation of the MVR evaporation system, first do other necessary inspections, and then fully open the air suction inlet gate valve of the separation equipment, the secondary steam pipeline and condensate pipeline are all unblocked, and there is no condensate on the top of the heating chamber of the heating equipment The non-condensable gas outlet valve at the outlet and the top of the condensate tank is fully opened, the external vent valve of the non-condensable gas connecting pipeline is fully opened, and the valve connected to the vacuum system is closed first.

[0009] 2. Start and run the MVR compressor, completely close the non-condensable gas outlet valve on the top of the heating chamber after normal start, and use the air medium to preheat the secondary steam pipeline and heating equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com