Automatic sewage suction device and filter device

A technology of automatic sewage suction and sewage suction port, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, which can solve the problems that the filter element is easy to be blocked, inconvenient to use, and affects the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

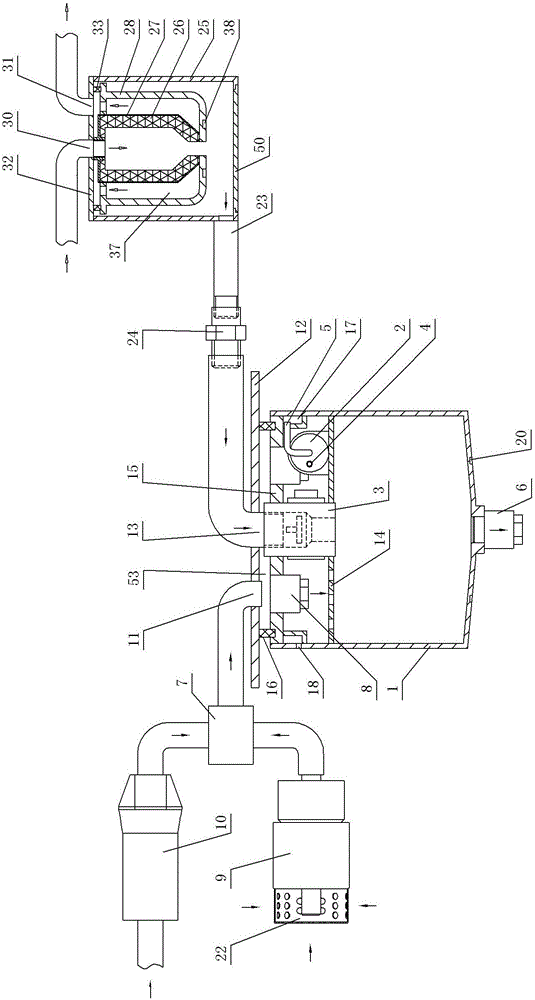

[0059] Embodiment one: see figure 1 , Figure 10 , Figure 11 , Figure 12 , in the figure, the automatic sewage suction device contains a sewage suction mechanism and a control circuit. The sewage suction mechanism contains a sewage suction tank and a vacuum pump 2. The upper part of the sewage suction tank 1 is provided with a sewage suction port 13, and the sewage suction port 13 is provided with a sewage suction port. When the solenoid valve 3 of the sewage suction port is opened, the sewage suction port 13 communicates with the interior of the sewage suction tank, the suction port 4 of the vacuum pump 2 communicates with the interior of the sewage suction tank, and the exhaust port 5 of the vacuum pump 2 communicates with the outside world , The bottom of the sewage suction tank is provided with a sewage outlet, the sewage outlet is provided with a sewage outlet valve, and the power supply end of the sewage suction electromagnetic valve 3 and the vacuum pump 2 is connec...

Embodiment 2

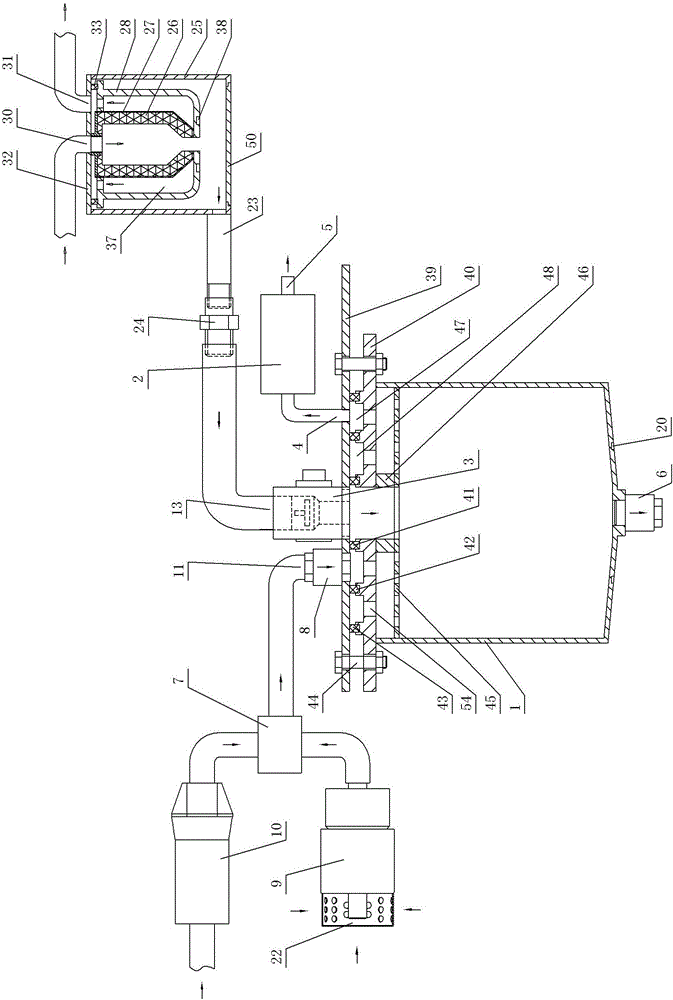

[0077] Embodiment two: see figure 2 , Figure 10 , Figure 11 , Figure 12 , the numbers in the figure are the same as those in Embodiment 1, which represent the same meaning, and the working process is basically the same, and the similarities will not be repeated. Fixed plate 39, the installation fixed plate 39 is positioned at the top of tank body 1; The upper port communicates with the sewage suction port 13; the lower port of the cleaning check valve 8 vertically passes through the mounting plate 39 and is sealed and connected with the mounting plate 39, and the upper port of the cleaning check valve 8 communicates with the cleaning material inlet 11; the vacuum pump 2. Installed outside the tank body 1, the suction port 4 of the vacuum pump 2 passes through the installation fixing plate 39 vertically and is sealed with the installation fixing plate 39; the upper surface of the top plate 40 of the tank body 1 is provided with three concentric annular sealing rings , t...

Embodiment 3

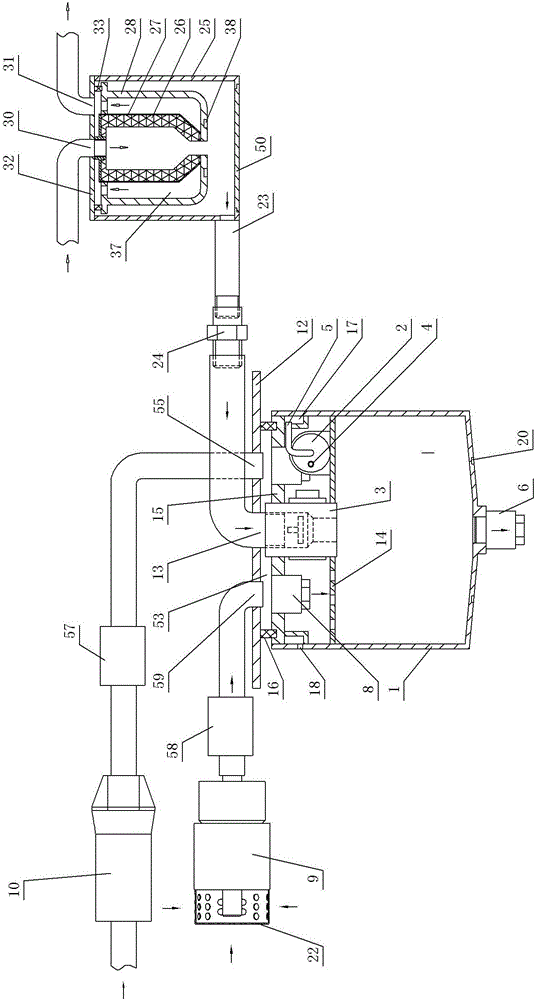

[0079] Embodiment three: see image 3 , Figure 10 , Figure 11 , Figure 13 , the numbers in the figure are the same as those in Embodiment 1, which represent the same meaning, and the working process is basically the same, and the similarities will not be repeated. The difference is that the sewage suction mechanism also includes a gas pump 9 and a liquid pump 10, The top of the dirt suction tank is also provided with a gas cleaning inlet 59, a liquid cleaning inlet 55 and a cleaning check valve 8, and the gas cleaning inlet 59 and the liquid cleaning inlet 55 communicate with the inside of the dirt suction tank through the cleaning check valve 8; The outlet is communicated with the gas cleaning inlet 59 through the gas cleaning electromagnetic valve 58, and the outlet of the liquid pump 10 is communicated with the liquid cleaning inlet 55 through the liquid cleaning electromagnetic valve 57; the gas pump 9, the liquid pump 10, the gas cleaning electromagnetic valve 58 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com