Thin-wall inner flanging C-shaped steel truss connectors and composite truss

A technology of inward flanging and C-shaped steel, which is applied in the direction of truss structures, truss beams, joists, etc., can solve problems such as damage to the connecting structure, and achieve the effect of reducing self-weight, not easy to slip, and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

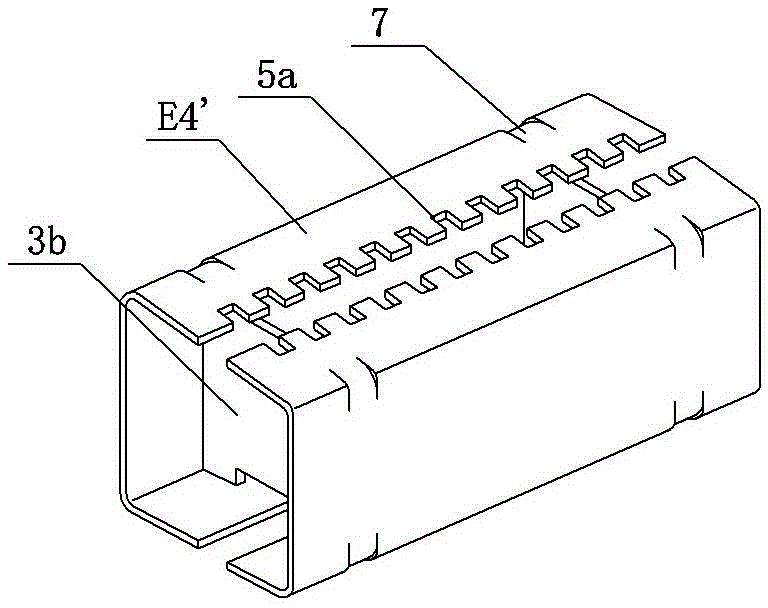

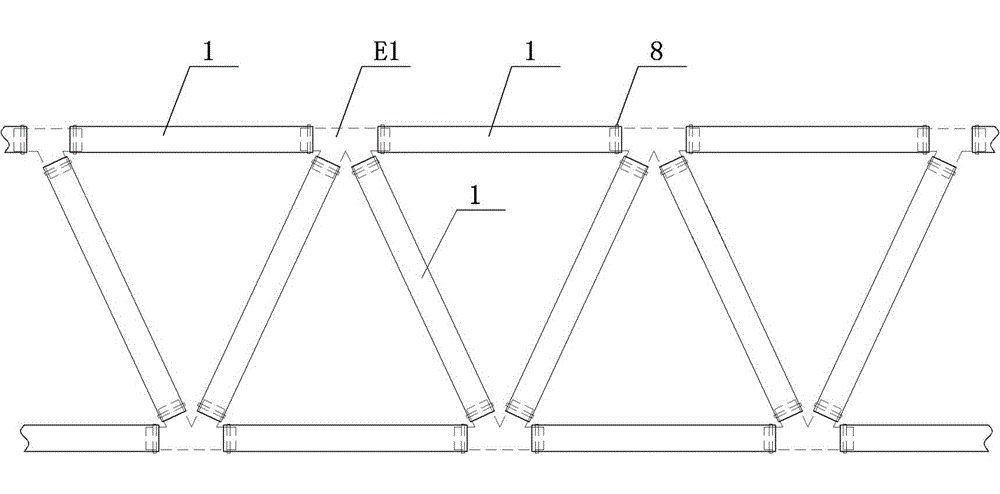

[0027] Embodiment 1: see image 3 and Figure 4 , the double thin-walled inner flanged C-shaped steel truss connector E1 with inner flanges is welded with at least two oblique plugs on the sides of two butted but gap-fitted channel-shaped steel plates. The corresponding plugs are buckled but fit in clearance; the inner side of the grooved steel plate and the oblique plug match the welding web at least at the end position, and the outer surface of the grooved steel plate and the oblique plug is provided with a positioning groove for punching or punching; each web An outwardly opening relief groove 4 is arranged between the plate and the grooved steel plate or the two side plates of the oblique plug. On the outside of the channel-shaped steel plate and the oblique plug, a locking groove 7 is arranged, and the locking groove 7 is arranged at a position corresponding to the web.

Embodiment 2

[0028] Example 2: see Figure 5 , single thin-walled inner flanged C-shaped steel truss connector E2 with inner flanged, at least two oblique plugs are welded on the side of a channel-shaped steel plate, the oblique plugs are groove-shaped, and the inner side of the channel-shaped steel plate and oblique plugs Match the welding web at least at the end position, and set punching or punching positioning grooves on the outer surface of the channel steel plate and the oblique plug; between each web and the two side plates of the channel steel plate or the oblique plug, there is an outward Opening give way slot4.

Embodiment 3

[0029] Embodiment 3: see Image 6 and Figure 7The structure of the double-thin-walled inner-flange C-shaped steel truss connector E3 with inner flanges is basically the same as that of the double-thin-walled inner-flange C-shaped steel truss connector E1 with inner flanges described in Embodiment 1. The difference is that the outer surface of the grooved steel plate and the oblique plug is provided with a positioning groove for punching. The punching positioning groove is located on the edge and has a convex-concave structure; it can be realized by punching or shearing. The webs of the connectors are connected to each other by reinforcing the connecting plates to increase their strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com