Lossless detection method for strata pressure movement law

A non-destructive testing and regular technology, applied in mining installations, mining equipment, earth-moving drilling and other directions, can solve the problems of distortion, the difference in the force of the monitoring results, and the inability to carry out the monitoring of the force of the bolt in a large area, so as to reduce the number of personnel. Casualty accidents, the effect of efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

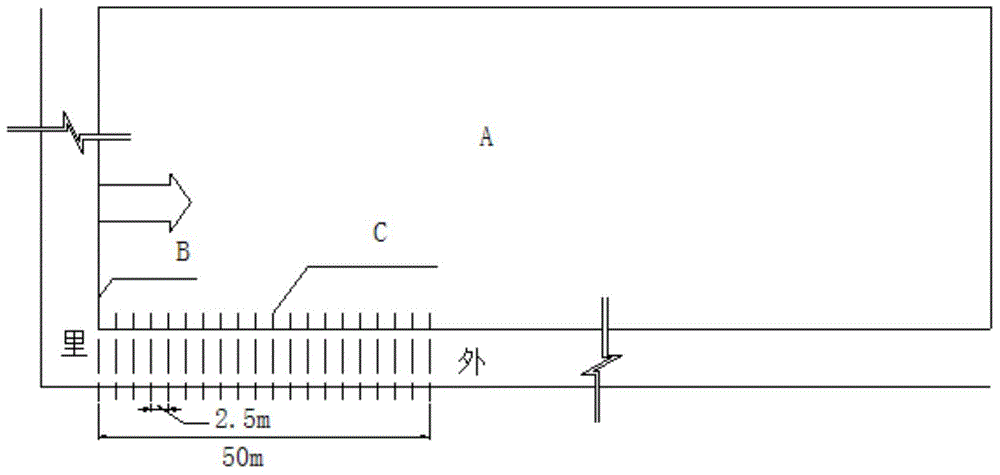

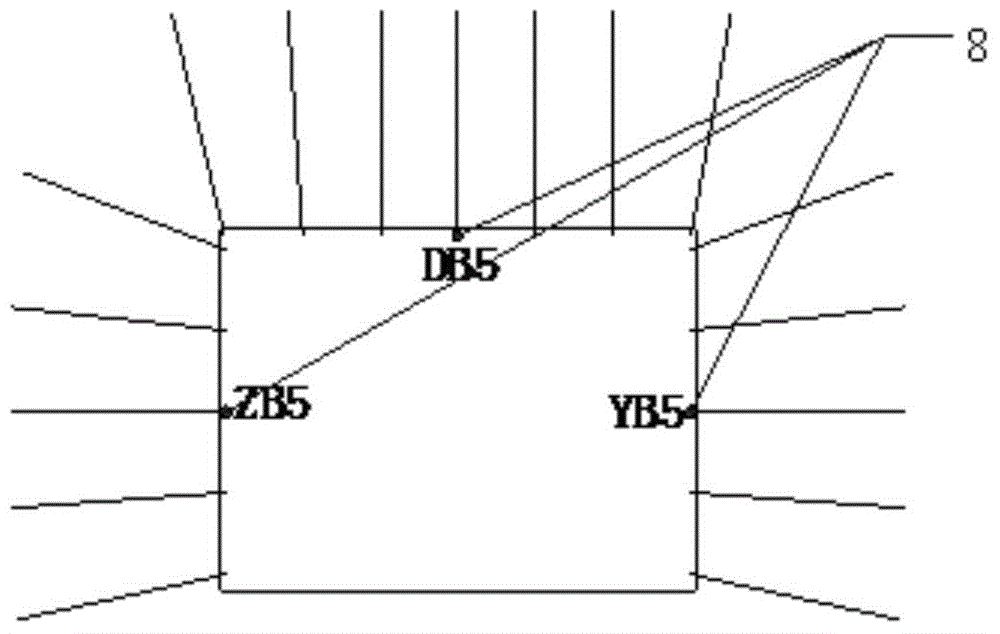

[0032] Such as figure 1 As shown, as the coal mining face advances, in the mining roadway, starting from the end of the coal mining face, along the roadway axis forward 50m in the roadway, set a group of anchors every 3 rows of anchor rods (about 2.5m apart) Rod axial force test section, the roof of each group of test sections and the number of anchor bolts that need to be tested for anchor bolt axial force, such as figure 1 with figure 2 shown. figure 1 A in the figure is the coal mining face, B is the end of the working face, C is the test section, and the arrow points to the advancing direction.

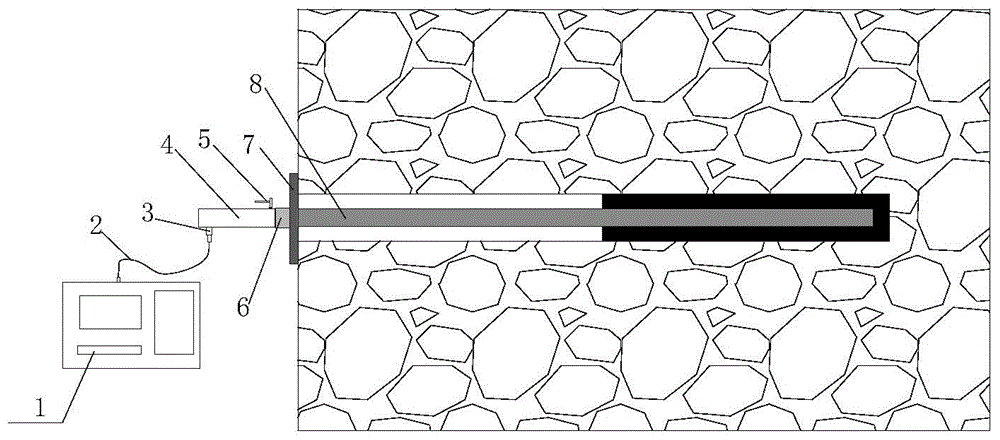

[0033] Use the CWM3.7 mining intrinsically safe bolt non-destructive testing system to carry out the bolt axial force test on the numbered bolts, such as image 3 shown. The leaking end of the test anchor rod 8 is equipped with an anchor rod nut 6 and a tray 7 from the outside to the inside. Screw the sleeve 4 on the leaking end of the test anchor 8, so that the sleeve is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com