Two-inlet one-outlet type tall faucet valve element

A faucet and spool technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problems of complex structure of the main body of the faucet, limitation of the center distance of the water inlet hole, etc., and achieve the advantages of convenient implementation, reduced use, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

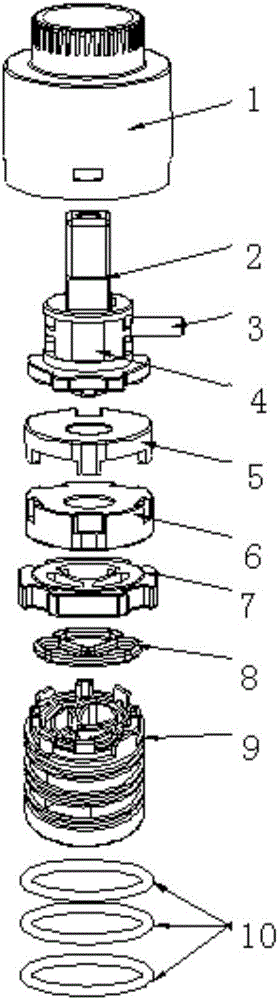

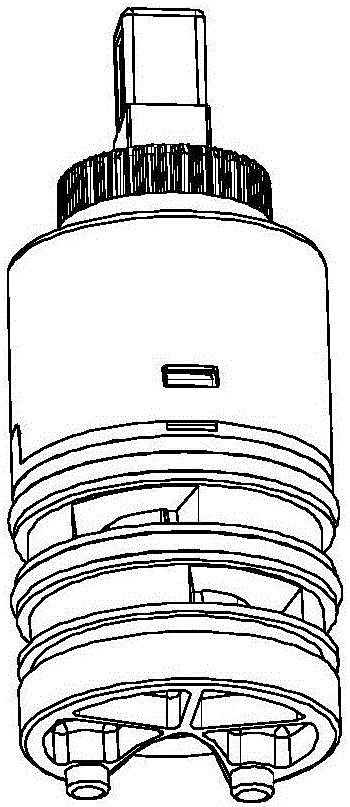

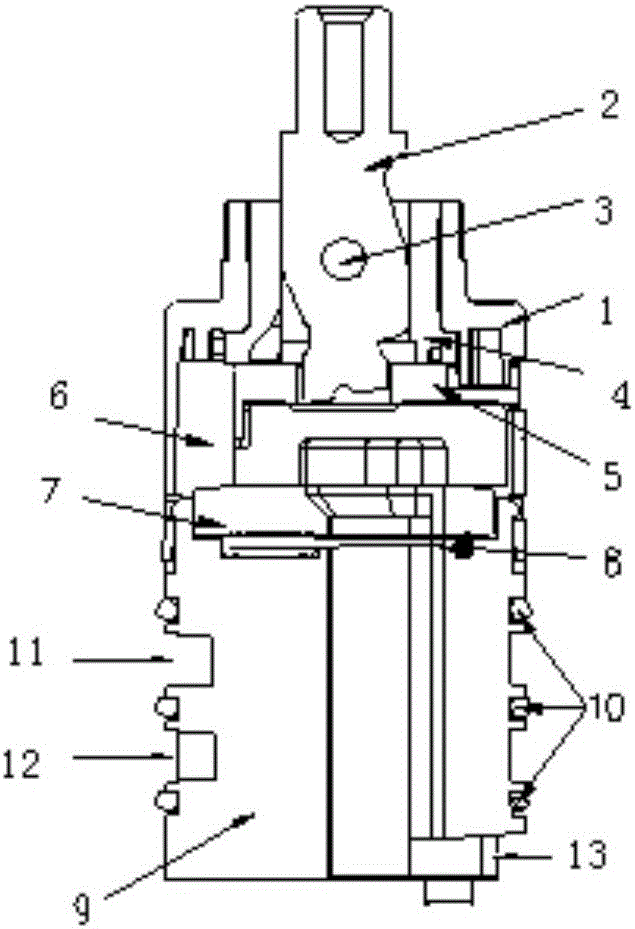

[0014] Embodiment 1 Two-inlet and one-outlet high-foot valve core of faucet

[0015] refer to Figure 1-4 , a two-in-one-out faucet high-foot valve core, including a valve core body 1, a valve stem 2 installed in the valve core body 1 sequentially from top to bottom, a bracket 4, and a pin shaft 3 arranged in the middle of the valve stem 2 , dial 5, moving valve plate 6, static valve plate 7, inner sealing ring 8, base 9 and O-ring 10 arranged on both sides of the base 9, the dial 5 is arranged at the bottom of the valve stem 2, so that the valve The rod 2 is embedded in the dial 5, the bracket 4 is tightly arranged on the outer periphery of the valve rod 2, and a first water inlet 11 and a second water inlet 12 are respectively arranged on one side of the base 9 in a vertical direction, and on the other side of the base 9 A water outlet 13 is provided at the lower end of the side, and the first water inlet 11 and the second water inlet 12 are arranged in the middle of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com