Cold-strip steel edge drop method through working roll asymmetric shifting control

A technology for edge thinning and cold-rolling strip steel, which is applied in rolling mill control devices, metal rolling, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The tapered roll is placed on different racks, and the effect of improving strip edge thinning is different. Putting it on the 1# rack can improve 40%, 2# rack can improve 30%, and the total improvement effect of the other racks does not exceed 30% %. Therefore, in consideration of equipment investment, edge thinning control effect, equipment operation cost, etc., it is suggested to add asymmetric roll shifting of work rolls to the 1#-3# stands of the tandem cold rolling mill during the implementation process.

[0054] Instrument and hardware configuration scheme of the present invention are:

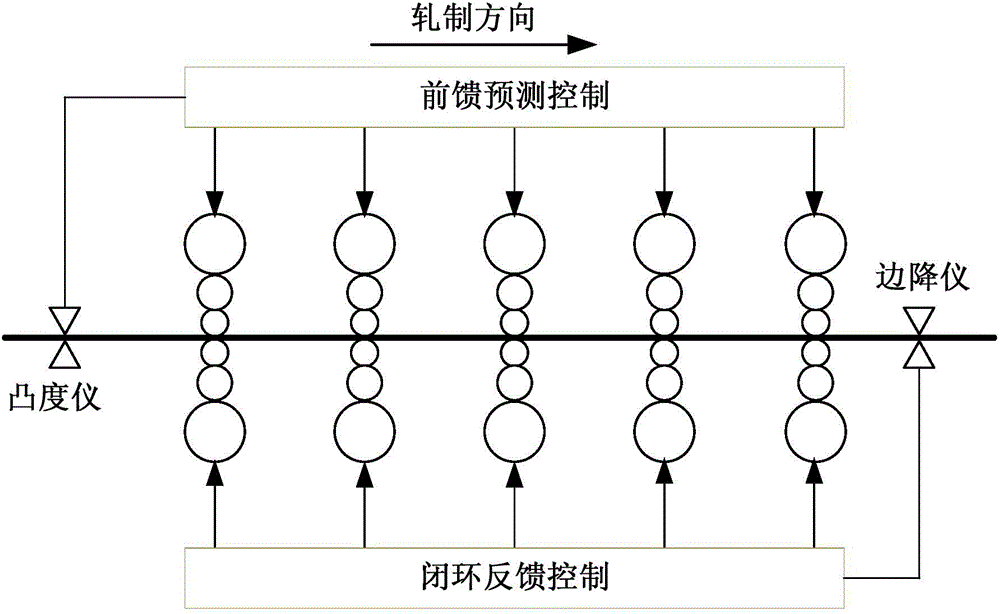

[0055] The cold tandem mill is equipped with an entrance multi-point crown gauge, which has the function of measuring width.

[0056] The cold tandem mill is equipped with an exit multi-point crown gauge and an exit multi-point edge drop instrument, which have the strip edge positioning function.

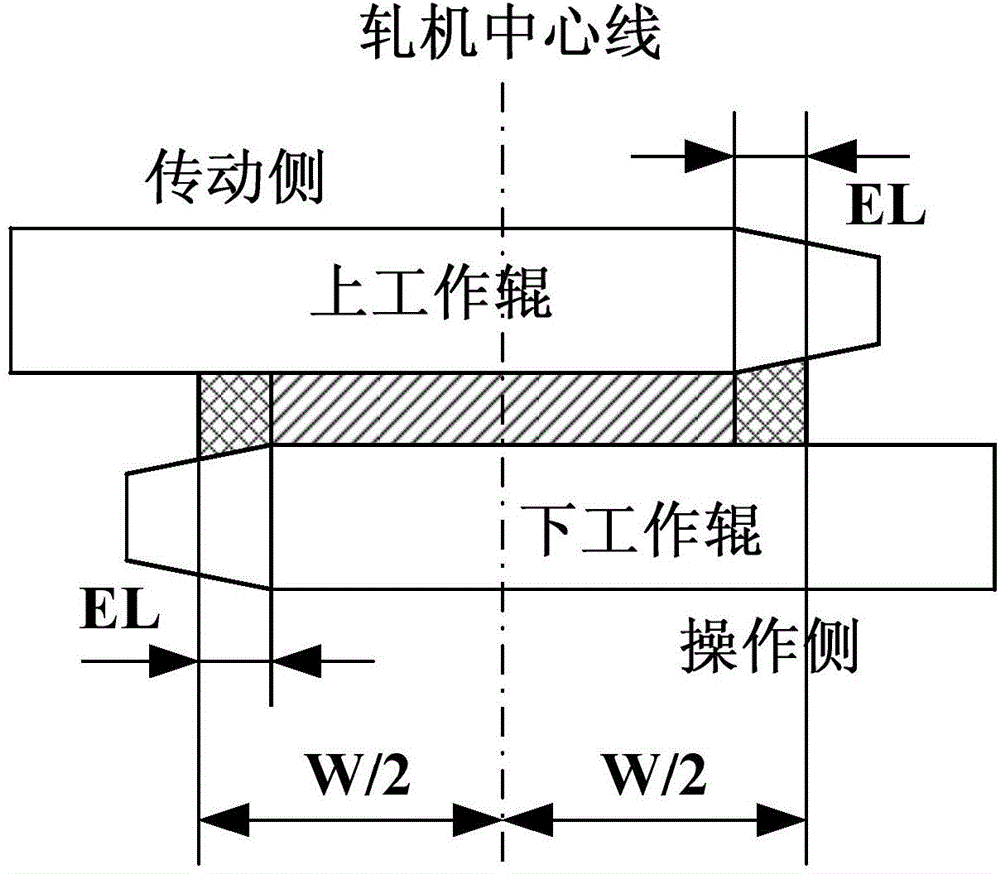

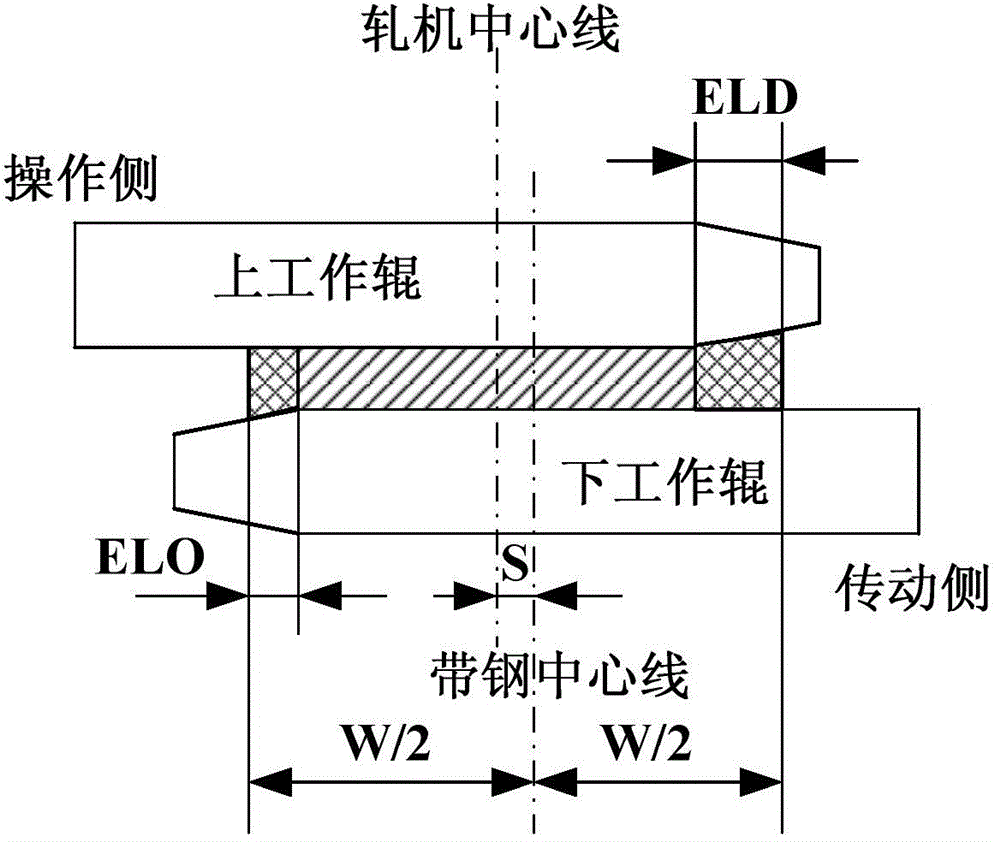

[0057] T-WRS work rolls are adopted; both the upper and lower work rolls can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com