All-glass vacuum heat collecting tube with anti-bump tail end

A vacuum heat collection tube and all-glass technology, which is applied to solar collectors, solar collectors, and heating devices using working fluids, and can solve the problem of air leakage in all-glass vacuum tubes, easy knocking at the end of the pointed outer tube, Problems such as loss of use value, to achieve the effect of not easy to slip, increase protection performance, and prevent bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

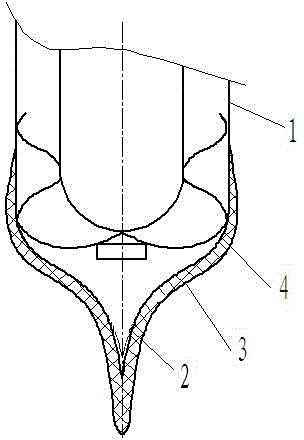

[0008] Such as figure 1 As shown, a full-glass vacuum heat collecting tube with anti-collision at the tail end includes an outer glass tube 1 and an outer tube tail end 2 formed after the outer glass tube is evacuated, and an elastic protective cap 3 is set on the outside of the outer tube tail end 2. And extend from the outer tube tail end 2 to the straight tube end of the outer glass tube 1.

[0009] The shape of the inner hole of the elastic protective cap 3 matches the shape of the outer tube tail end 2 and the straight tube end of the outer glass tube 1 , so that the outer tube tail end 2 is tightly embedded in the inner hole of the elastic protective cap 3 . The outer diameter of the elastic protective cap 3 gradually shrinks forward from the end of the straight tube of the outer glass tube 1, so that the toughness of the front end of the elastic protective cap 3 is enhanced, it is easier to stick to the surface of the outer glass tube, and it is not easy to fall off. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com