A kind of preparation method of natural graphite-based composite electrode material

A natural graphite and composite electrode technology, applied in graphite, battery electrodes, circuits, etc., can solve the problems of poor charge-discharge reversibility and cycle performance, low chemical reactivity, complex preparation process, etc., and achieve good reversibility of charge-discharge reaction, Excellent cycle performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

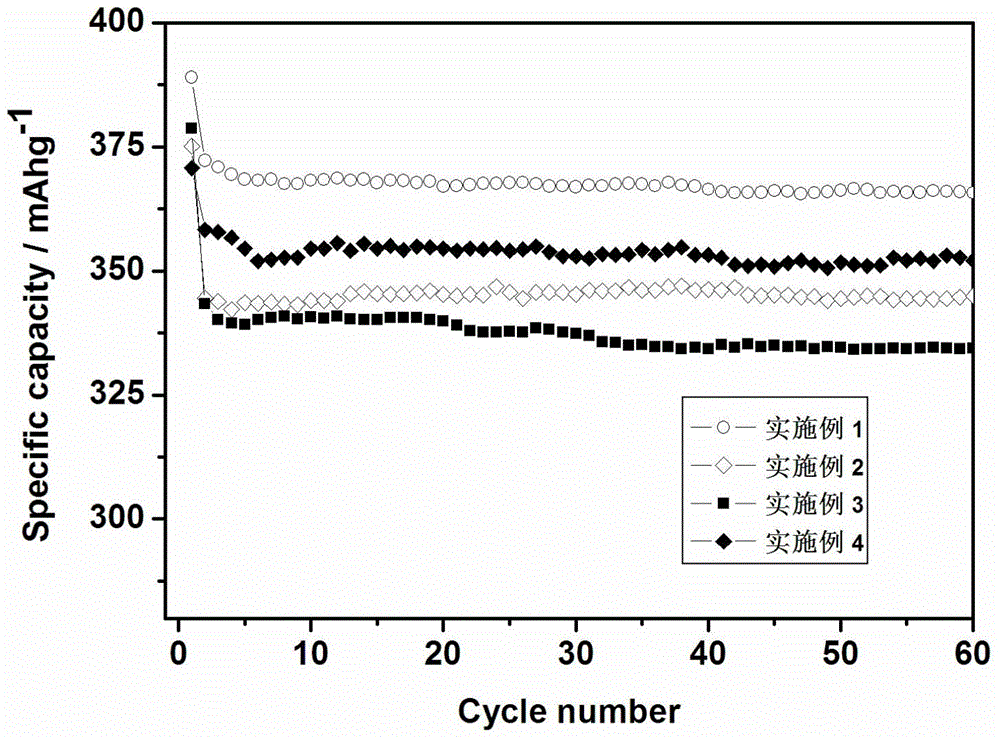

Embodiment 1

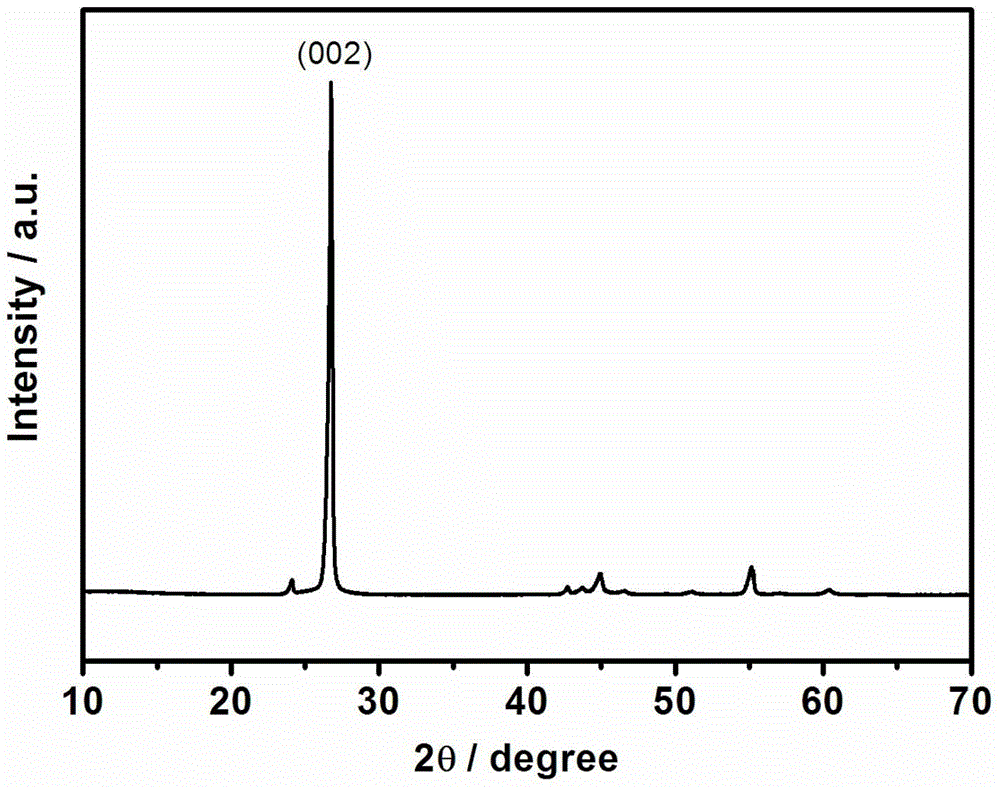

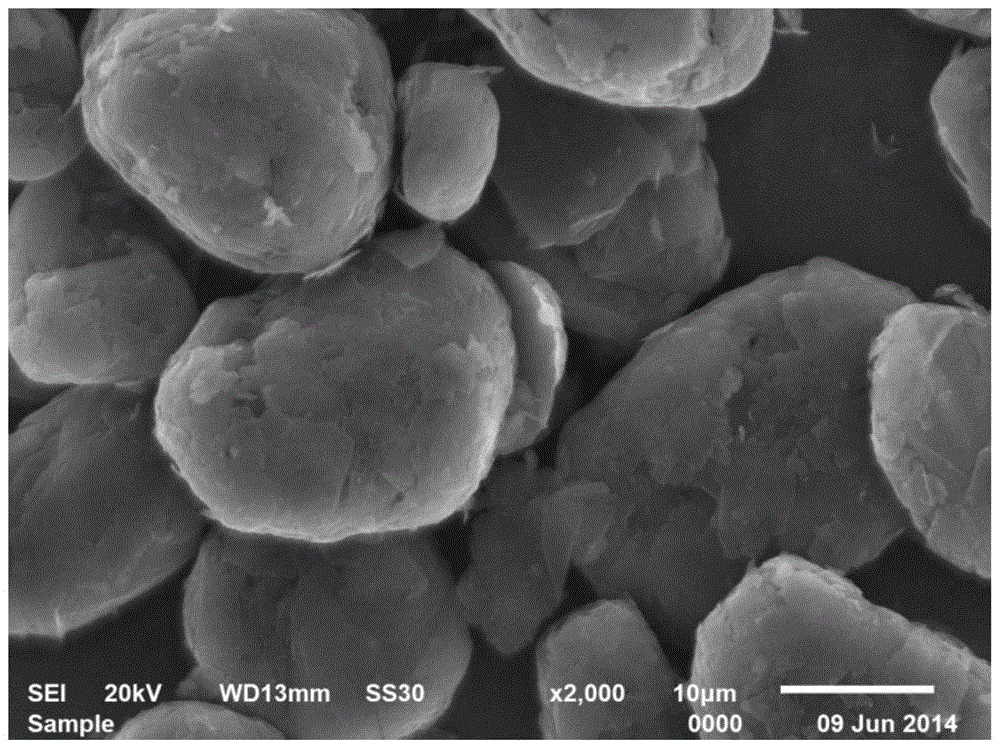

[0027] A preparation method of natural graphite-based composite electrode material, the steps are as follows:

[0028] Mechanically process the natural flake graphite to the average particle size D 50 =17μm, then in a smaller argon gas atmosphere (air flow rate of 3cm 3 / min) from room temperature to 200°C at a heating rate of 5°C / min and kept for 1 hour, and activated natural graphite was obtained after cooling. The melamine was then placed in a muffle furnace and raised from room temperature to 520° C. at a rate of 5° C. / min in an air atmosphere, and kept there for 2 hours. After cooling, a light yellow powder was obtained. Then, the activated natural graphite and the light yellow powder were mixed in a V-type mixer at a mass ratio of 95wt%:5wt% for 2 hours, and the rotating speed was set at 100 rpm. Gained mixed product is in argon atmosphere (argon flow velocity is 40cm 3 / min) from room temperature to 700°C at a rate of 5°C / min and kept at 700°C for 6 hours, after cool...

Embodiment 2

[0030] A preparation method of natural graphite-based composite electrode material, the steps are as follows:

[0031] Mechanically process the natural flake graphite to the average particle size D 50 =17μm, then in a smaller argon gas atmosphere (air flow rate of 3cm 3 / min) from room temperature to 200°C at a heating rate of 5°C / min and kept for 1 hour, and activated natural graphite was obtained after cooling. The melamine was then placed in a muffle furnace and raised from room temperature to 520° C. at a rate of 5° C. / min in an air atmosphere, and kept there for 2 hours. After cooling, a light yellow powder was obtained. Then, the activated natural graphite and the light yellow powder were mixed in a V-type mixer at a mass ratio of 90wt%: 10wt% for 2 hours, and the rotating speed was set at 150 rpm. Gained mixed product is in nitrogen atmosphere (nitrogen gas flow velocity is 40cm 3 / min) from room temperature to 700°C at a rate of 5°C / min and kept at 700°C for 6 hours...

Embodiment 3

[0033]A preparation method of natural graphite-based composite electrode material, the steps are as follows:

[0034] Mechanically process the natural flake graphite to the average particle size D 50 =17μm, then in a smaller argon gas atmosphere (air flow rate of 3cm 3 / min) from room temperature to 200°C at a heating rate of 5°C / min and kept for 1 hour, and activated natural graphite was obtained after cooling. The melamine was then placed in a muffle furnace and raised from room temperature to 520° C. at a rate of 5° C. / min in an air atmosphere, and kept there for 2 hours. After cooling, a light yellow powder was obtained. Then, the activated natural graphite and the light yellow powder were mixed in a V-type mixer at a mass ratio of 85wt%: 15wt% for 2 hours, and the rotating speed was set at 100 rpm. Gained mixed product is in argon atmosphere (argon flow velocity is 40cm 3 / min) from room temperature to 800°C at a rate of 5°C / min and maintained at 800°C for 6 hours, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com