An electrochemical energy storage device

An electrochemical and energy storage technology, applied in electrode carriers/current collectors, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as limiting the application of energy storage devices, reducing cell rate performance and low temperature performance, and achieving manufacturing costs. The effect of low cost, excellent electrochemical performance, high puncture resistance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

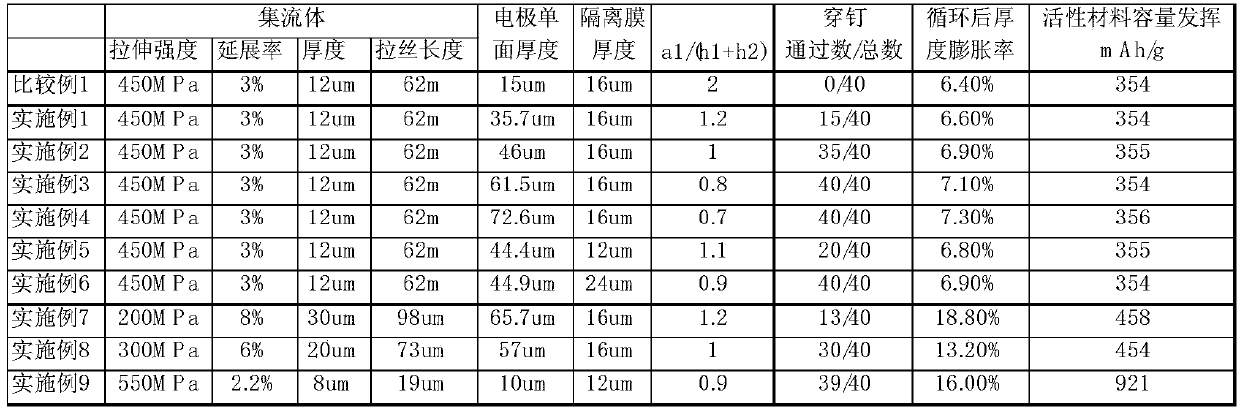

[0031] The difference from Comparative Example 1 is that the thickness of the single-side negative electrode coating formed after cold pressing is 35.7 μm.

[0032] The rest are the same as those of Comparative Example 1 and will not be repeated here.

Embodiment 2

[0034] The difference from Comparative Example 1 is that the thickness of the single-side negative electrode coating formed after cold pressing is 46 μm.

[0035] The rest are the same as those of Comparative Example 1 and will not be repeated here.

Embodiment 3

[0037] The difference from Comparative Example 1 is that the thickness of the single-side negative electrode coating formed after cold pressing is 61.5 μm.

[0038] The rest are the same as those of Comparative Example 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com