Anti-aging silane modified polyether sealant for buildings and preparation method thereof

A silane-modified polyether, anti-aging technology, applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of poor aging resistance and long-term service life, and improve cohesion and strength , Durability improvement, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

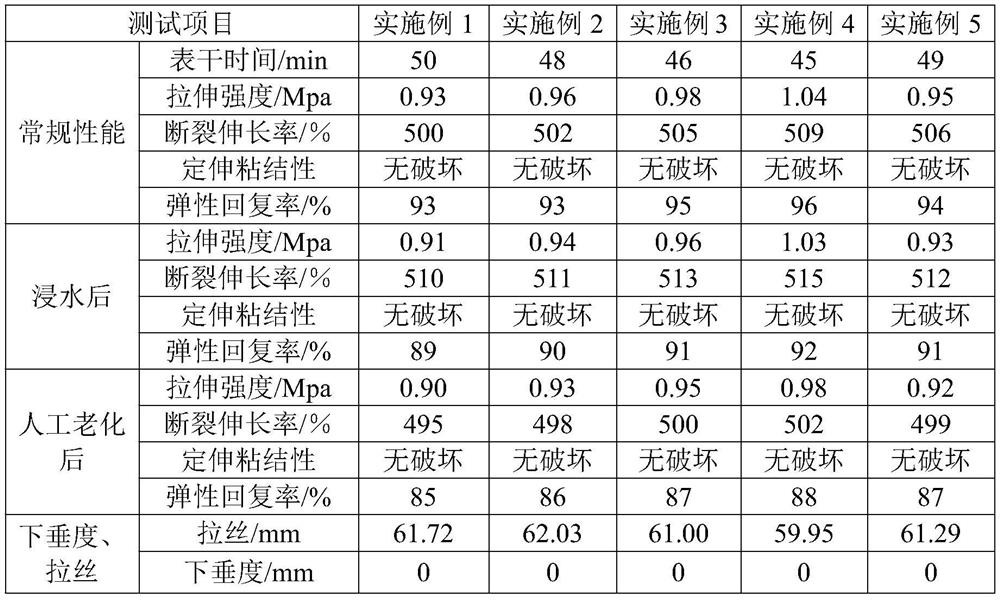

Examples

Embodiment 1

[0029] An aging-resistant silane-modified polyether sealant for construction, prepared from the following raw materials in parts by weight: 80 parts of silane-modified polyether resin, 1 part of SBS modifier, 20 parts of polypropylene glycol PPG3000, and 30 parts of nano-calcium carbonate 30 parts of heavy calcium powder, 6 parts of TCA-BEAT titanate coupling agent, 0.1 part of SZ99P antifungal agent, 0.1 part of dibutyltin dilaurate, 0.5 parts of fumed silica, 1 part of organic bentonite, vinyl 0.6 parts of trimethoxysilane, 10100.3 parts of antioxidant, 0.5 parts of light stabilizer UV7700, CeO 2 10 parts, 3 parts of rutile titanium dioxide, 2 parts of carbon black.

[0030] A preparation method of anti-aging silane modified polyether sealant for building, comprising the following steps:

[0031] A. After surface-treating the nano-calcium carbonate with stearic acid, mix it with heavy calcium and heat it to 80° C. to pre-remove water for 20 hours to obtain the filler and se...

Embodiment 2

[0035] An aging-resistant silane-modified polyether sealant for buildings, prepared from the following raw materials in parts by weight: 90 parts of silane-modified polyether resin, 5 parts of SBS modifier, 15 parts of phthalate, 35 parts of nano calcium carbonate, 35 parts of heavy calcium powder, 5 parts of TCA-BEAT titanate coupling agent, 0.3 part of SZ99P antifungal agent, 0.2 part of stannous octoate, 0.2 part of tin butyrate, 0.5 part of fumed silica , 1 part of organic bentonite, 0.4 parts of vinyl triethoxysilane, 0.4 parts of vinyl tris(2-methoxyethoxy) silane, 10100.3 parts of antioxidant, 0.5 parts of light stabilizer UV7700, Pr 6 o 11 10 parts, 0.1 part of rutile titanium dioxide, 5 parts of carbon black.

[0036]A preparation method of anti-aging silane modified polyether sealant for building, comprising the following steps:

[0037] A. After surface-treating the nano-calcium carbonate with stearic acid, mix it with heavy calcium and heat it to 82°C to pre-remo...

Embodiment 3

[0041] An aging-resistant silane-modified polyether sealant for buildings, prepared from the following raw materials in parts by weight: 110 parts of silane-modified polyether resin, 8 parts of SBS modifier, 10 parts of polypropylene glycol PPG3000, and 50 parts of nano-calcium carbonate 50 parts of heavy calcium powder, 1 part of TCA-BEAT titanate coupling agent, 1 part of KH792 silane coupling agent, 0.8 part of SZ99P antifungal agent, 0.3 part of chelated tin, 0.3 part of dibutyltin dilaurate , 0.3 parts of trialkylamine, 0.5 parts of fumed silica, 1 part of organic bentonite, 0.2 parts of vinyl tris (2-methoxyethoxy) silane, 10100.3 parts of antioxidant, 0.5 parts of light stabilizer UV7700 , CeO 2 2 parts, 2 parts of rutile titanium dioxide, 20 parts of carbon black.

[0042] A preparation method of anti-aging silane modified polyether sealant for building, comprising the following steps:

[0043] A. After surface-treating the nano-calcium carbonate with stearic acid, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com