High-dispersibility vortex powder selecting machine

A high-dispersity, powder-separator technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

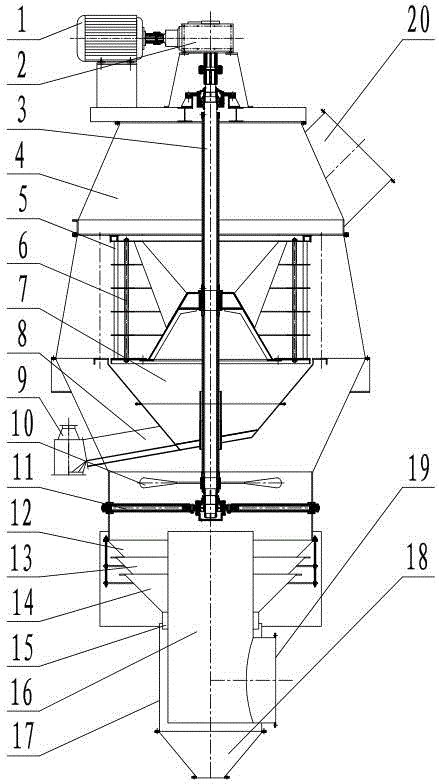

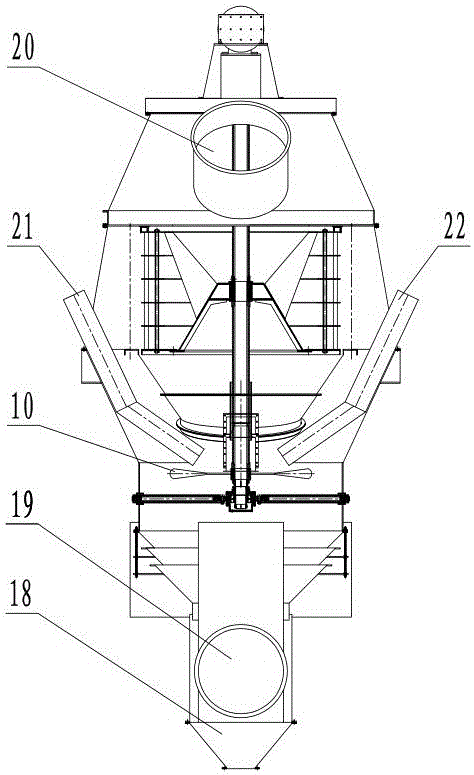

[0010] figure 1 with figure 2 Among them, the high-dispersion eddy current powder separator includes a housing 4, a cage rotor 6, a motor 1, a reduction box 2, a transmission shaft 3, a feeding pipe, an air outlet pipe 20, a spreading disc 10, an air guide vane 5 and Meal collection cone 18. Both the motor 1 and the reduction box 2 are arranged on the top of the casing 4 . The motor 1 is connected to the reduction box 2, the upper end of the transmission shaft 3 is connected to the reduction box 2, the lower end of the transmission shaft 3 passes through the top of the casing 4 and is located in the casing 4, and the cage rotor 6 is arranged on the transmission shaft 3, and the cage rotor The outer side of 6 is equipped with a circle of described guide blades 5.

[0011] The above-mentioned high-dispersibility eddy current powder separator also includes a medium and coarse powder collecting cone 7, an upper collecting cone 12, a middle collecting cone 13, a lower collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com