Small-space automatic tube expansion robot

A robot and small space technology, applied in the field of boilers, can solve the problems of inconvenient manual expansion operation, narrow header space, poor working conditions, etc., to reduce the waiting time for cooling, reduce labor intensity, and automatically control the expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

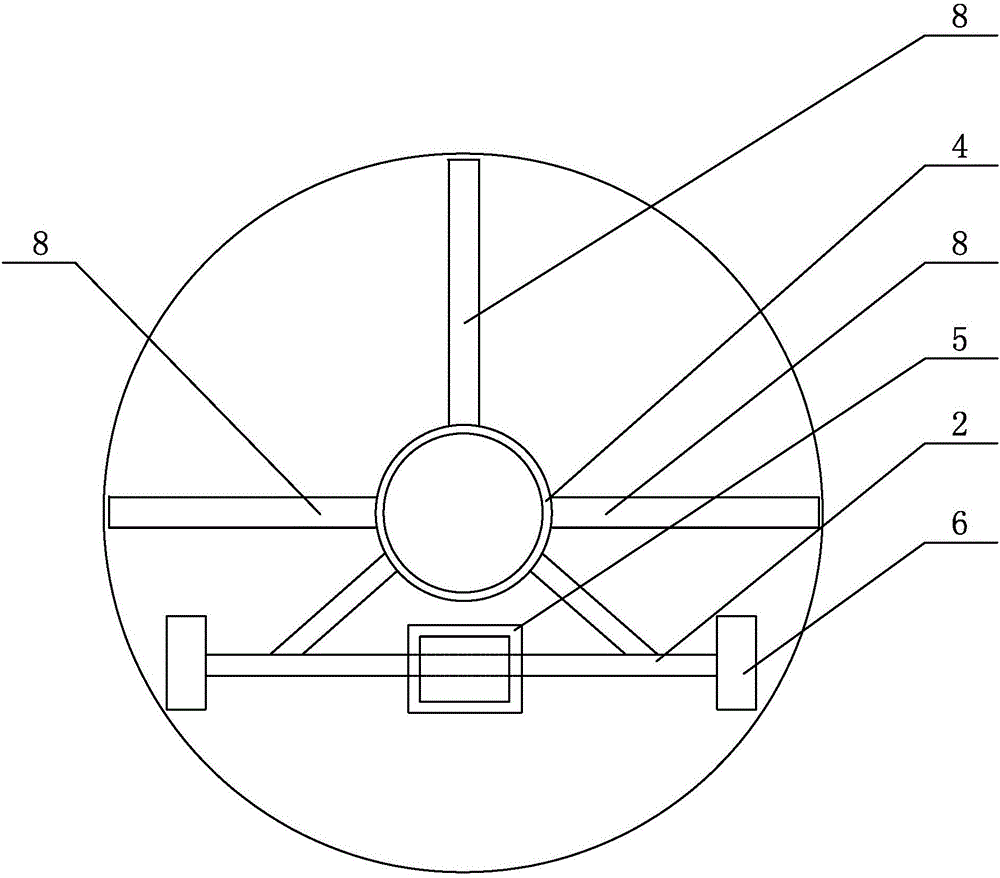

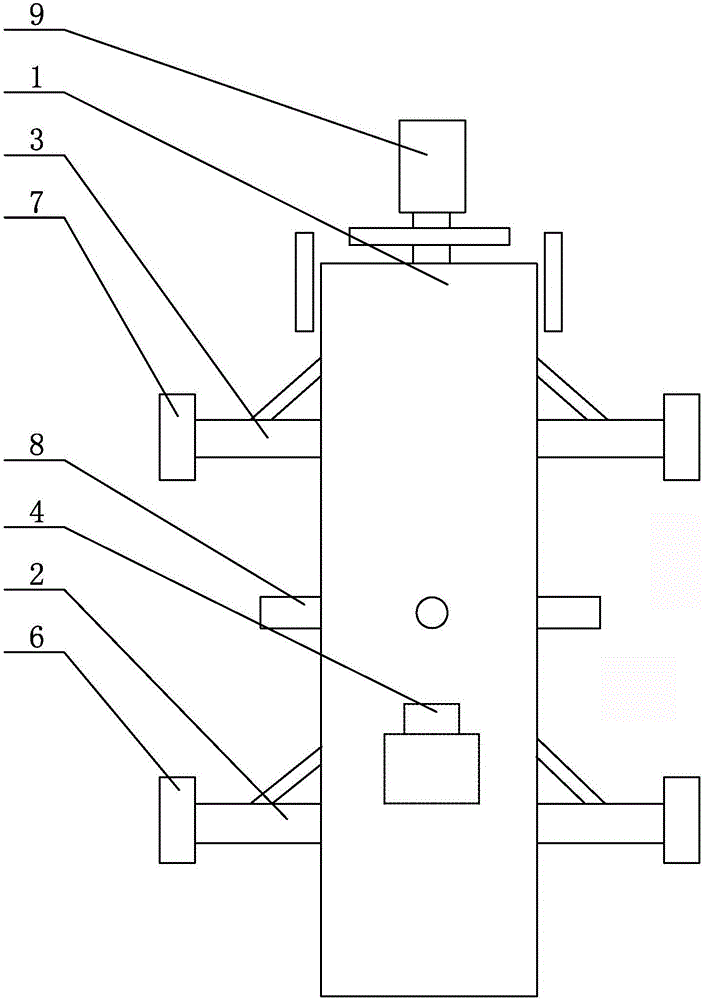

[0007] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a small-space automatic tube expanding robot described in this embodiment includes a robot main body 1, a walking driving shaft 2, a walking driven shaft 3, a walking hydraulic motor 4, a gearbox 5, a tube expander connecting mechanism, two A walking driving wheel 6, two walking driven wheels 7 and three fixed support cylinders 8, the walking driving shaft 2 and the walking driven shaft 3 are installed side by side in parallel on the robot main body 1 from front to back, and the walking driving shaft 2 The axes of the axis and the walking driven shaft 3 are perpendicular to the center line of the robot main body 1 along the length direction. A walking driving wheel 6 is respectively installed at both ends of the walking driving shaft 2, and a walking driving wheel 6 is respectively installed at both ends of the walking driven shaft 3. Walking driven wheel 7, walking hydraulic mo...

specific Embodiment approach 2

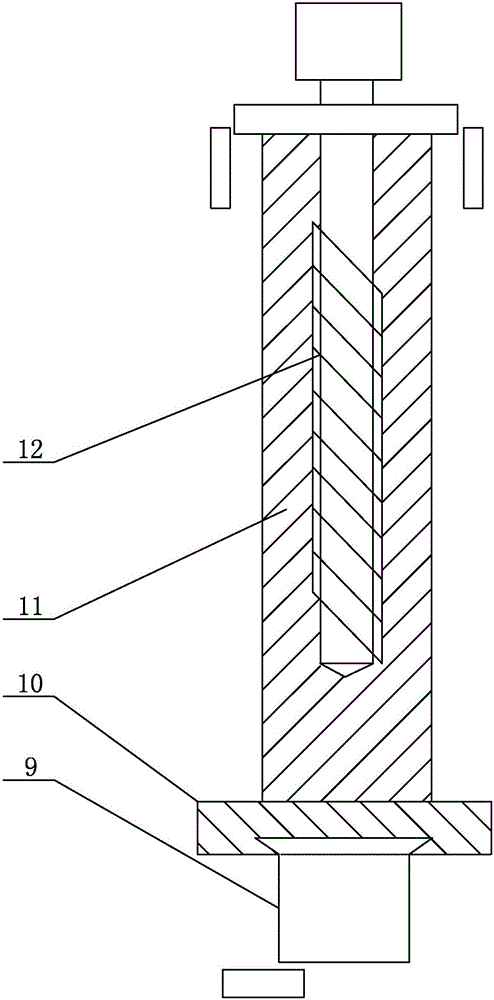

[0008] Specific implementation mode two: combination image 3 Describe this embodiment, the tube expansion connection mechanism of a small-space automatic tube expansion robot described in this embodiment includes a tube expander hydraulic motor 9, a slideway 10, a connecting shaft 11 and a lead screw 12, and the tube expander hydraulic motor 9 and The slideway 10 is connected, the slideway 10 is connected with one end of the connecting shaft 11 , and the lead screw 12 is inserted in the other end of the connecting shaft 11 .

[0009] In this embodiment, the slideway 10 is provided with a jacking cylinder. Other components and connections are the same as those in the first embodiment.

[0010] working principle

[0011] Step 1. Install the tube expander on the tube expander connection mechanism, start the walking hydraulic motor 4, and the walking hydraulic motor 4 drives the robot main body 1 to the tube expansion area, and control the tube expansion within the range of ±10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com