Automobile front door glass assembly and automobile front door assembly

A glass and front door technology, which is applied to doors, vehicle parts, door/window accessories, etc., can solve the problem of glass jamming in the front door glass lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

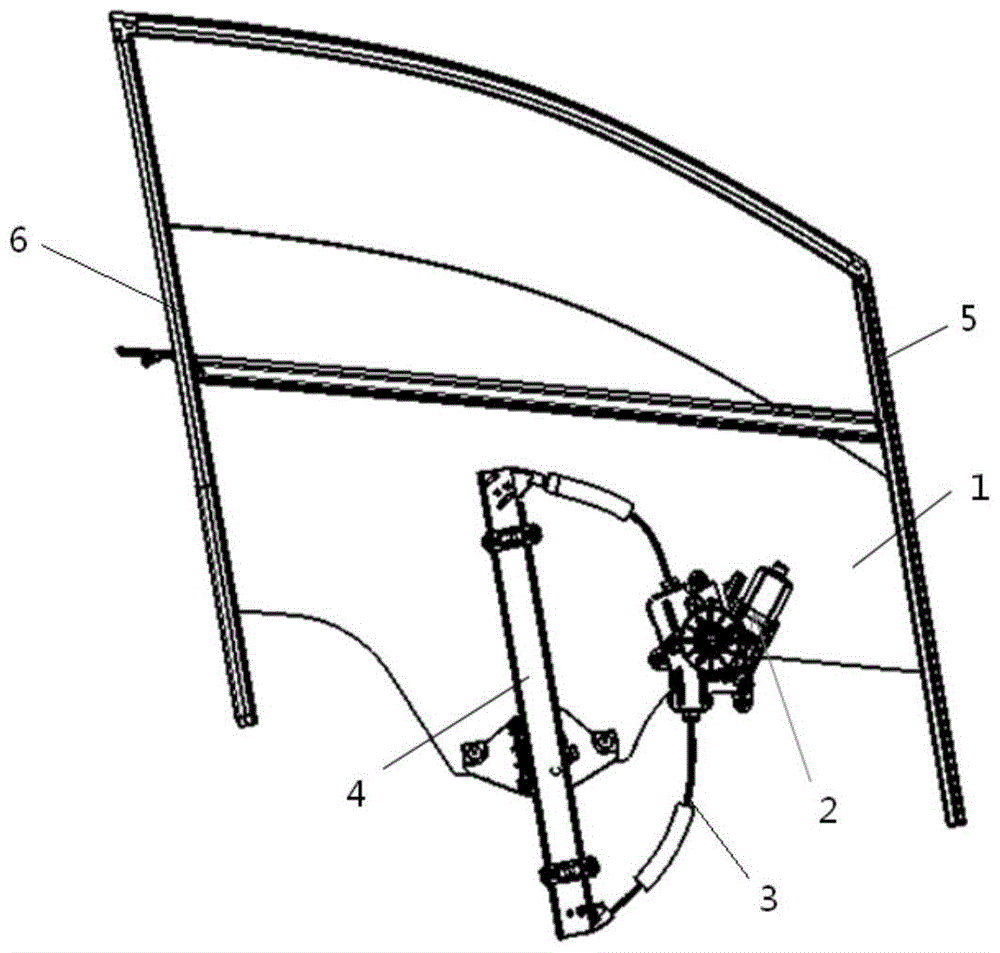

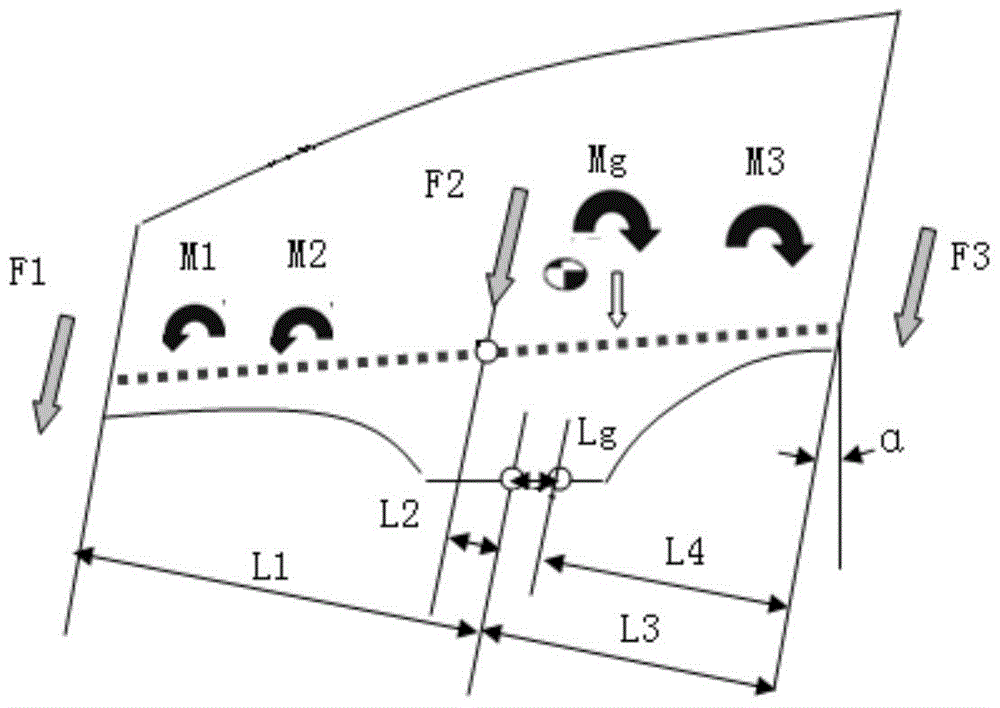

[0025] Such as Figure 1-4 As shown, an automobile front door glass assembly provided by an embodiment of the present invention includes a glass 1 and a monorail lifter, and the monorail lifter includes a motor 2, a cable 3 driven by the motor 2, and a slide rail 4 driven by the cable 3 , the slide rail 4 is fixed on the glass 1, and the slide rail 4 is fixed on the resistance fitting line of the glass 1. The resistance fitting line is fitted by the moment equilibrium points at each position of the glass 1 on the way up, and the moment equilibrium point is the following resistance The balance point: glass gravity, front trough resistance, rear trough resistance, water splitting bar resistance and rearview mirror resistance.

[0026] Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com