A double broken line tmd control system

A control system and broken-line technology, applied to building components, earthquake resistance, etc., can solve the problems of long TMD control system, great influence of building space layout, and large cross-sectional size, so as to achieve efficient use of building space and facilitate promotion , increase the effect of the basic cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

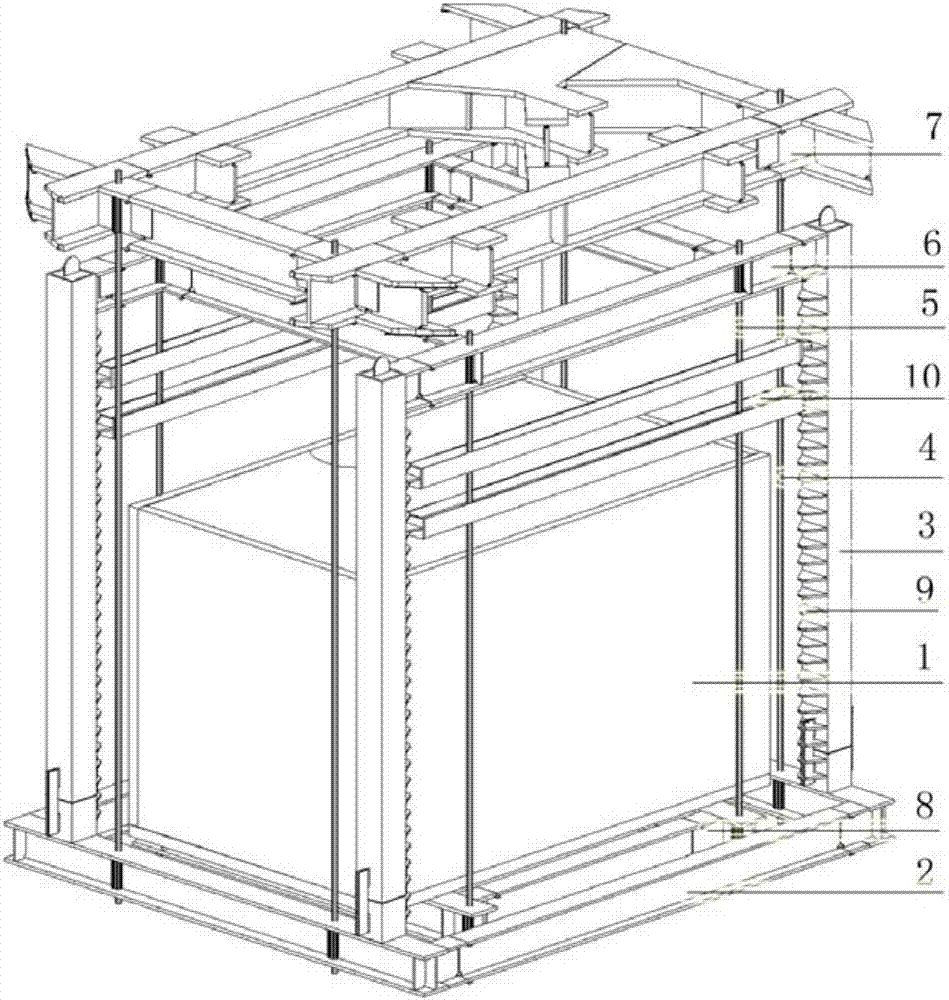

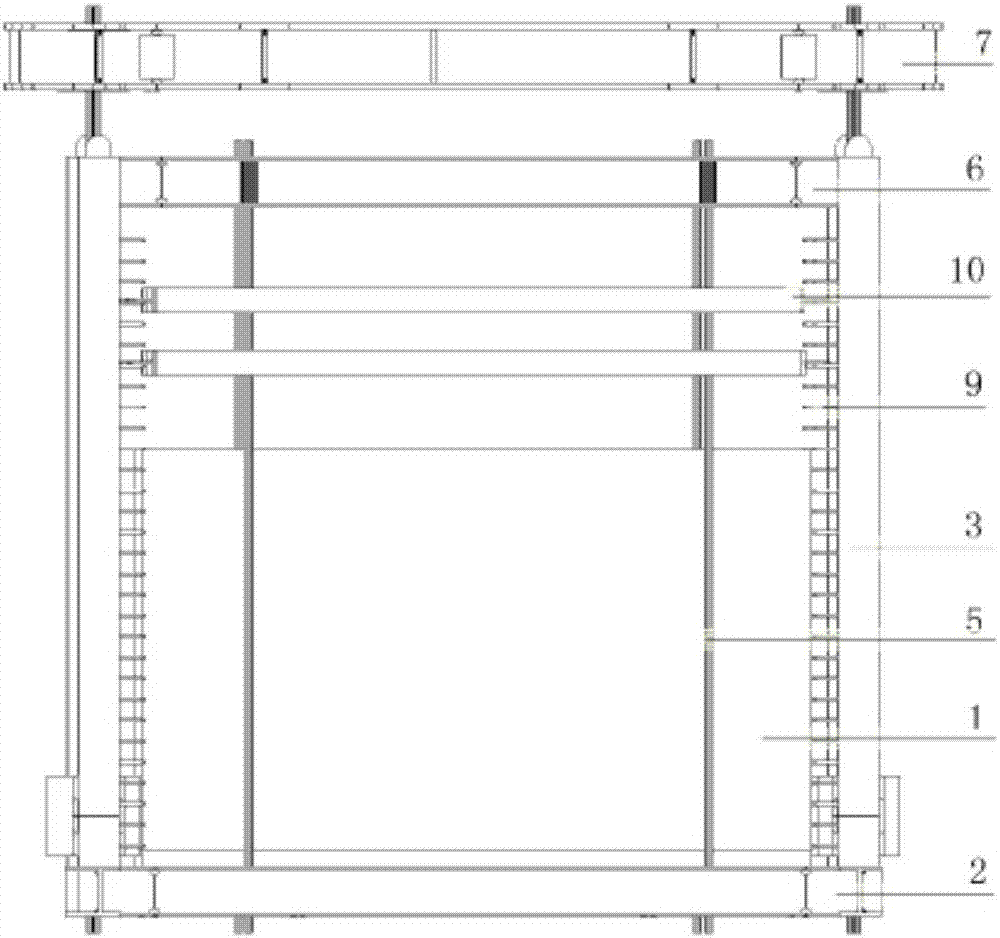

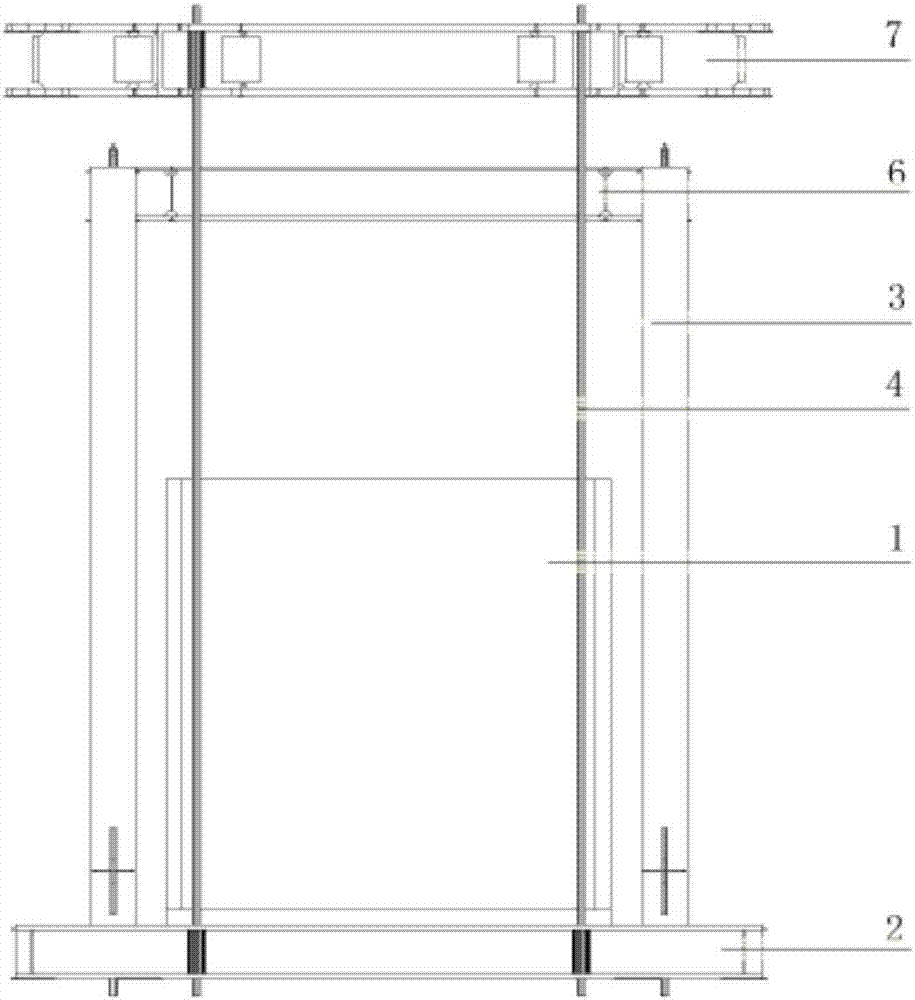

[0029] Refer to attached Figures 1 to 6 It can be seen that the double broken line TMD control system in this embodiment includes the main hanging point device 7, the primary suspension support mechanism, the primary suspension cable 4, the secondary suspension support mechanism, the secondary suspension cable 5, the mass block 1 and the damping Limiting device 12.

[0030] The main hanging point device 7 is fixedly connected with the building main structure. The primary suspension cable 4 is connected to the main body hanging point device 7 and the primary suspension support mechanism, the secondary suspension cable 5 is connected to the primary suspension support mechanism and the secondary suspension support mechanism, and the secondary suspension cable 5 is connected to the primary suspension support mechanism. The position of the connection point of the mechanism is higher than the position of the connection point between the primary suspension steel cable 4 and the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com