Automatic restoring quake-proof silo

A self-reset, silo technology, applied in earthquake resistance, building types, buildings, etc., can solve problems such as weak earthquake resistance and silos that do not have shock and shock absorption functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the basic structure is as described in the preceding paragraph, except that the stacking of multiple silo units 1 takes the form of connecting cylinders. That is, except the top silo unit 1 , the other silo units are equipped with a connecting cylinder 3 inside, and the connecting cylinder 3 protrudes from one end of the silo unit 1 .

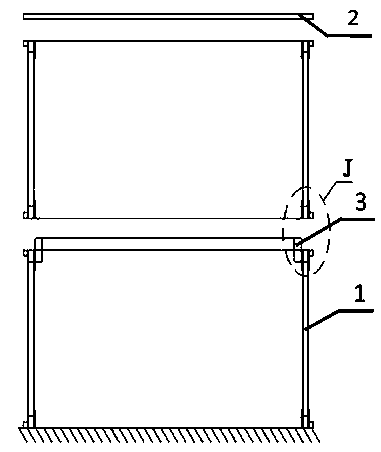

[0020] join figure 1 , including at least two stacked silo units 1, the interior of the lower silo unit 1 (ie, the lower silo) is installed with a connecting cylinder 3, and the connecting cylinder 3 extends out of the lower silo unit 1 (ie the upper end of the silo). When two silo units 1 are stacked, the connecting cylinder 3 protrudes into the interior of the upper silo unit 1 . Since the connecting cylinder 3 serves as the inner cylinder of the lower silo and is fixedly connected to the lower silo, when the upper silo is placed on the lower silo, the connecting cylinder 3 constrains the lateral dislocation betwe...

Embodiment 2

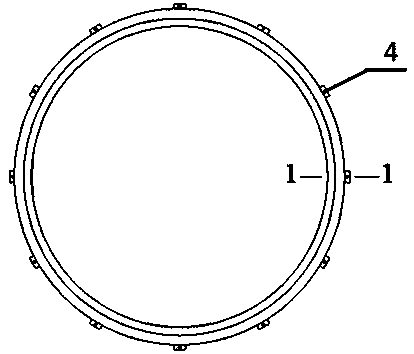

[0024] The basic structure of this embodiment is the same as that of Embodiment 1, except that there are two silo units 1 , and each end of each silo unit 1 is evenly equipped with at least 12 anchor holes 5 . In this embodiment, due to stacking, the two silo units are called the lower silo and the upper silo respectively.

[0025] see figure 1 , the figure shows the separated state of the two silo units 1 . Wherein, the lower silo is in contact with the ground, and the upper silo has a cover 2 . The outer walls of the upper and lower silos are respectively provided with 24 anchor holes 5, 12 at each end. The inside of the lower silo is connected with a connection cylinder 3 . The connecting cylinder 3 is fixedly connected with the inner wall of the lower silo.

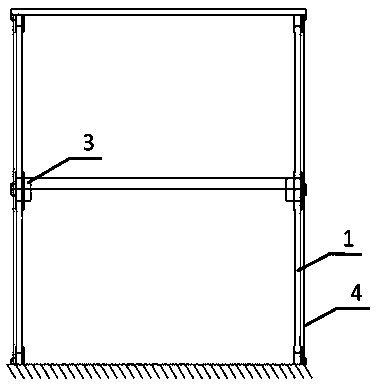

[0026] see figure 2 , place the upper silo on top of the lower silo. At this time, the connecting cylinder 3 extends into the inside of the upper silo, and has a certain gap with the inner wall of the upper sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com