A system and method for extracting coalbed methane from an old goaf

A technology for coalbed methane and old gobs, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high accident rate, difficult construction, low porosity rate, etc., and achieve economic cost saving , Increase the extraction volume of coalbed methane, increase the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated by the following examples, but not limited to the following examples.

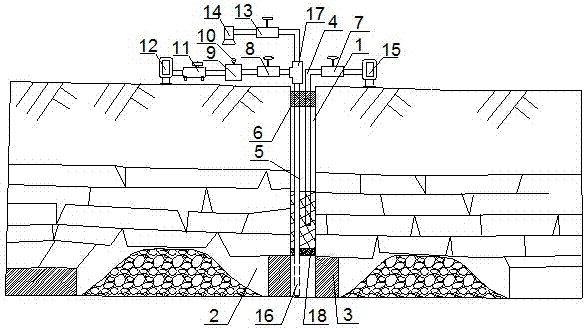

[0024] The present invention provides a system for extracting coalbed methane in an old goaf, comprising extraction drilling 1, extraction pipe 5, grouting pipe 4, valve I8, valve II13, valve III7, booster pump 11, N 2 Gas storage tank 12, gas collection tank 9, pressure gauge 10, tee pipe 17, grouting station 15, the extraction well 1 leads to the bottom of the coal pillar 3, and the extraction pipe 5 is sent to the coal pillar through the extraction well 1 3 Bottom; Drainage well 1 close to the ground is sealed by polyurethane plate 6, the drainage pipe 5 above the ground is connected to the tee pipe 17, one end of the tee pipe 17 is provided with a ground drainage station 14 and a valve II 13 in sequence, and the other end is provided with N 2 Gas storage tank 12, booster pump 11, gas collection tank 9, pressure gauge 10, valve I8, baffle plate 18 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com