Automatic fire extinguisher injection electric insulation performance testing device

An automatic test and fire extinguisher technology, applied in the direction of testing dielectric strength, etc., can solve the problems of low efficiency and large error in the test of fire extinguisher spray electrical insulation performance, and achieve the realization of automatic detection, improvement of detection quality and efficiency, and reduction of human interference factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

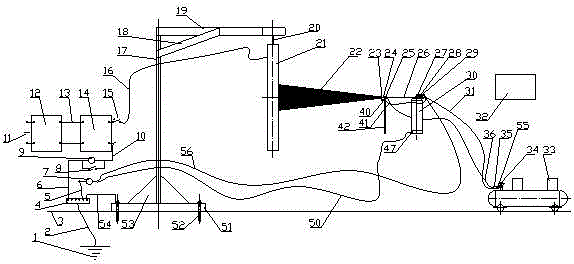

[0038] Such as figure 1 As shown, the automatic test device for spraying electrical insulation performance of fire extinguishers in this embodiment includes a pneumatic clamping and releasing mechanism and an electrical insulation testing mechanism.

[0039] The electrical insulation testing mechanism includes an input transformer 12 whose input end is connected to the input power supply 11 ; the output end of the input transformer 12 is connected to the input end of the test transformer 14 through the first wire 13 .

[0040] The negative pole of the output terminal of the transformer 14 for testing is connected to the negative terminal of the ammeter 9 for initial adjustment through the second wire 10 . The positive terminal of the ammeter 9 for initial adjustment is connected to the ground terminal 4 through the first ground wire 6, and the ground terminal 4 is connected to the ground body 1 through the second ground wire 2; the ammeter 9 for initial adjustment is connected...

Embodiment 2

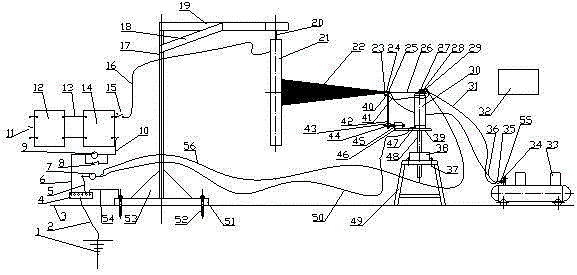

[0051] Such as image 3 As shown, the automatic test device for spraying electrical insulation performance of fire extinguishers in this embodiment includes a pneumatic clamping and releasing mechanism, an automatic positioning mechanism for fire extinguishers and an electrical insulation testing mechanism.

[0052] The electrical insulation testing mechanism includes an input transformer 12 whose input end is connected to the input power supply 11 ; the output end of the input transformer 12 is connected to the input end of the test transformer 14 through the first wire 13 .

[0053] The negative pole of the output terminal of the transformer 14 for testing is connected to the negative terminal of the ammeter 9 for initial adjustment through the second wire 10 . The positive terminal of the ammeter 9 for initial adjustment is connected to the ground terminal 4 through the first ground wire 6, and the ground terminal 4 is connected to the ground body 1 through the second groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com