Hybrid drive system with three-clutch automatic transmission and control method

An automatic transmission and hybrid technology, which is applied to the arrangement, control device, power device and other directions of multiple different prime movers of the general power plant, can solve the problem that the total power of the drive motor cannot always run, and the engine cannot be fully utilized. problem, to achieve the effect of high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

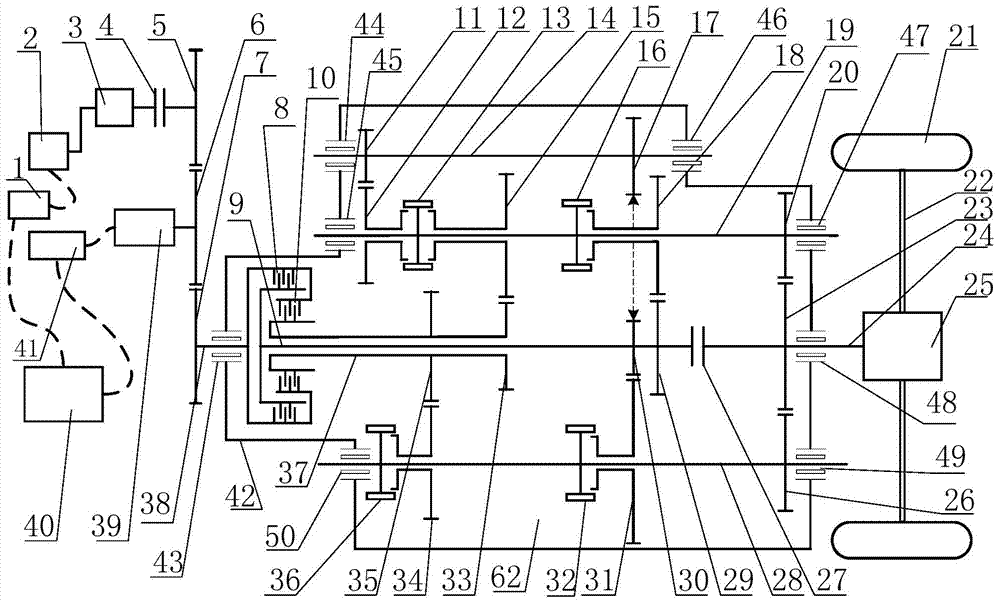

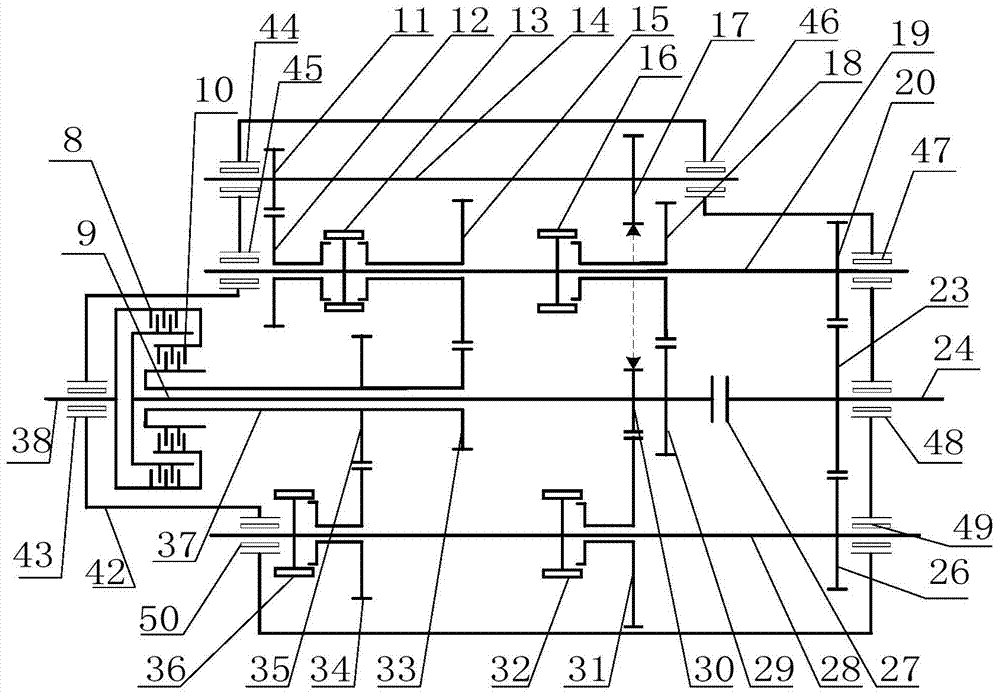

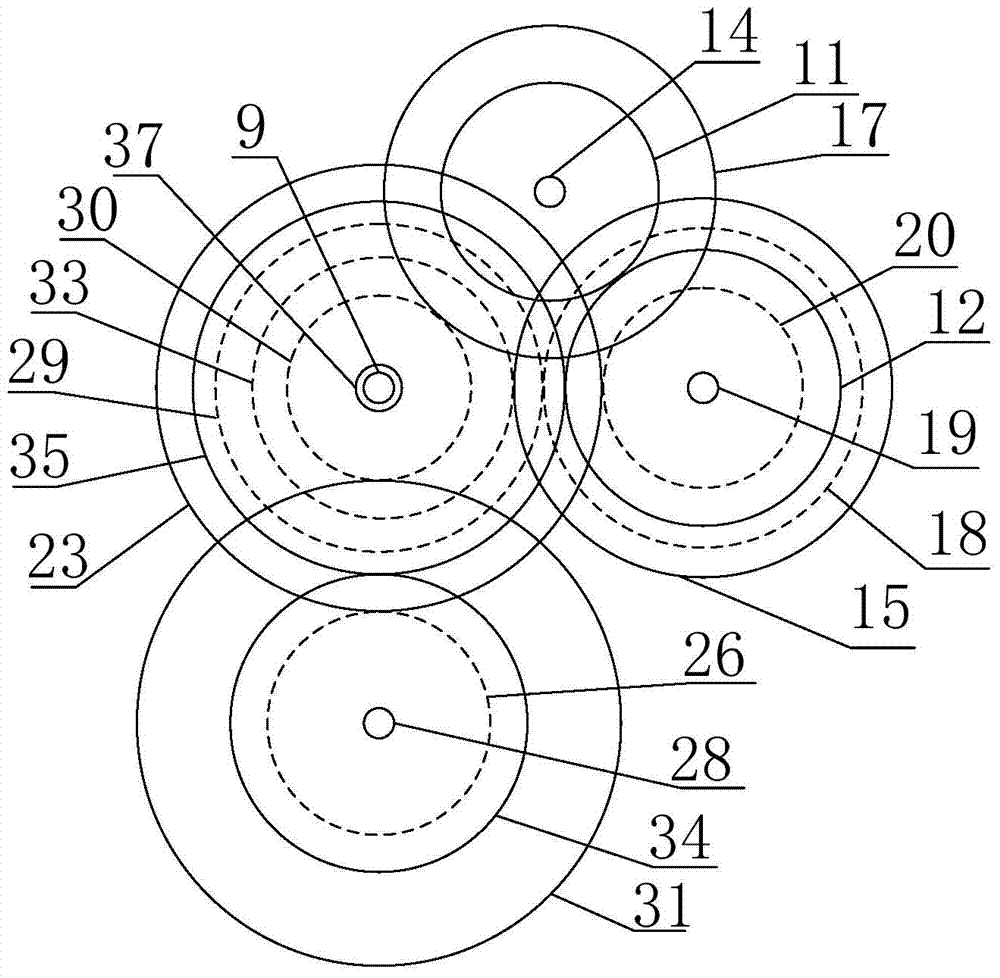

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

[0054] refer to figure 1 , the hybrid drive system with a three-clutch automatic transmission includes a first power converter 1, a starter / generator integrated machine 2, an engine 3, a fourth clutch 4, a fourth clutch output shaft gear 5, and a drive motor output shaft End gear 6, drive motor 39, energy storage device 40, second power converter 41, transmission input shaft end gear 7, three-clutch automatic transmission 62, differential 25, axle 22, wheels 21; wherein, the fourth clutch The output shaft end gear 5, the drive motor output shaft end gear 6, and the transmission input shaft end gear 7 constitute a hybrid drive system power coupling device.

[0055] There are two input shafts of the power coupling device: the fourth clutch output shaft and the drive motor 39 output shafts, the output shaft is the transmission input shaft 38, the output shaft 24 of the three-clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com