Patents

Literature

31results about How to "Fast gear shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

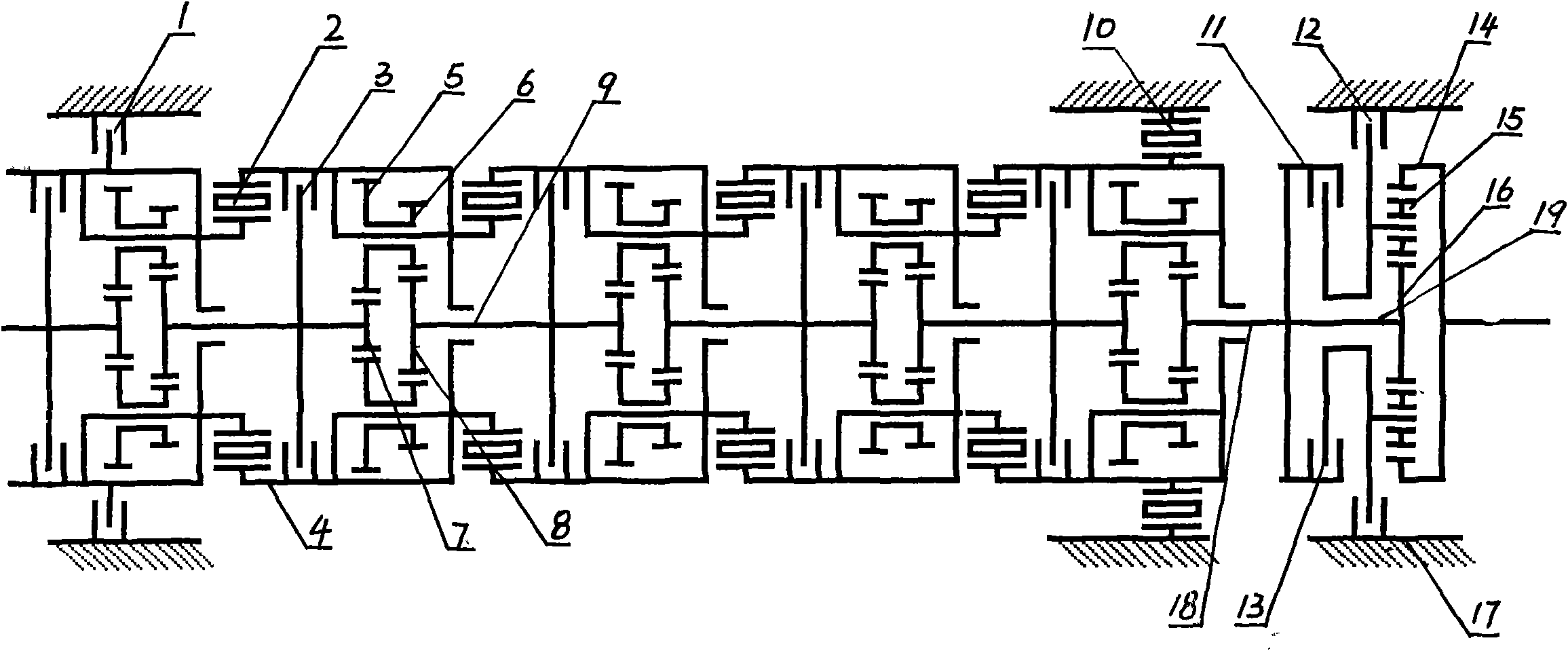

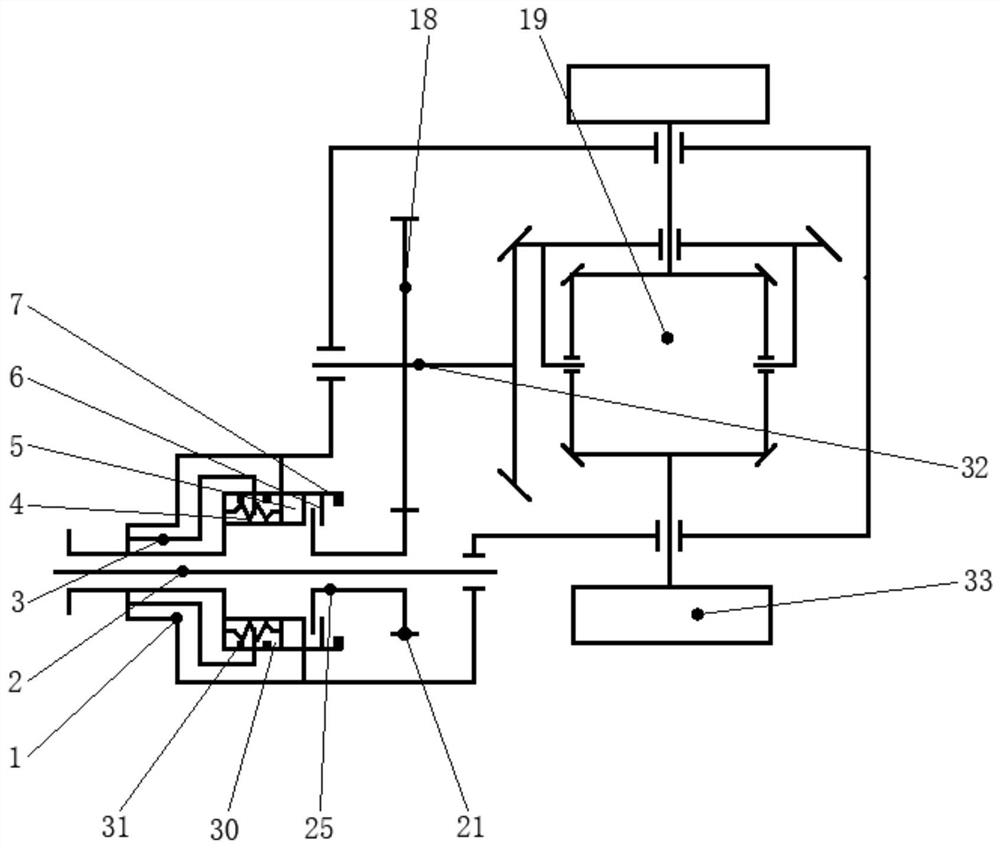

Planetary gearbox capable of directly shifting gears

InactiveCN101769365AFast gear shiftSimple designToothed gearingsGearing detailsModular unitGear wheel

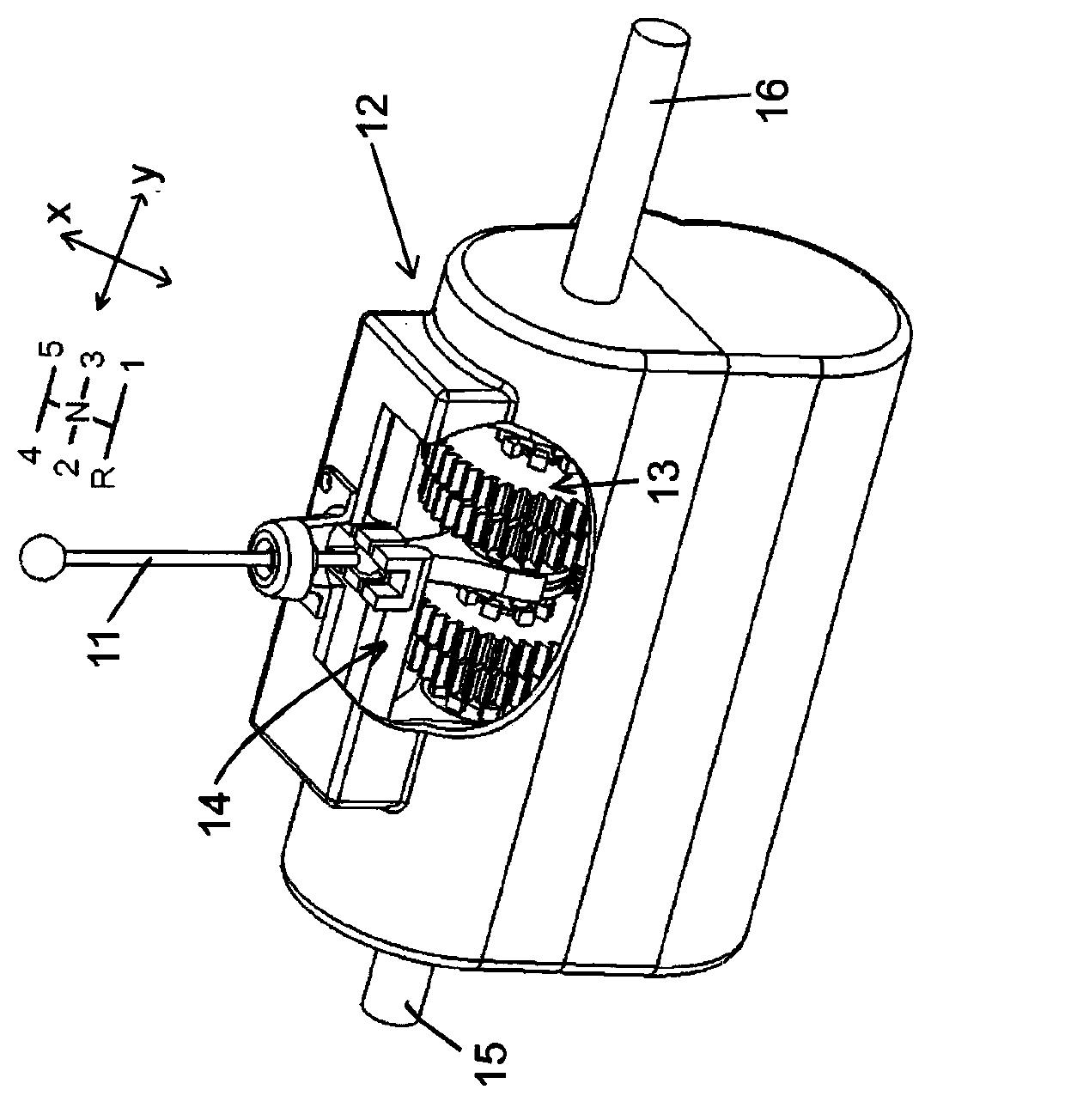

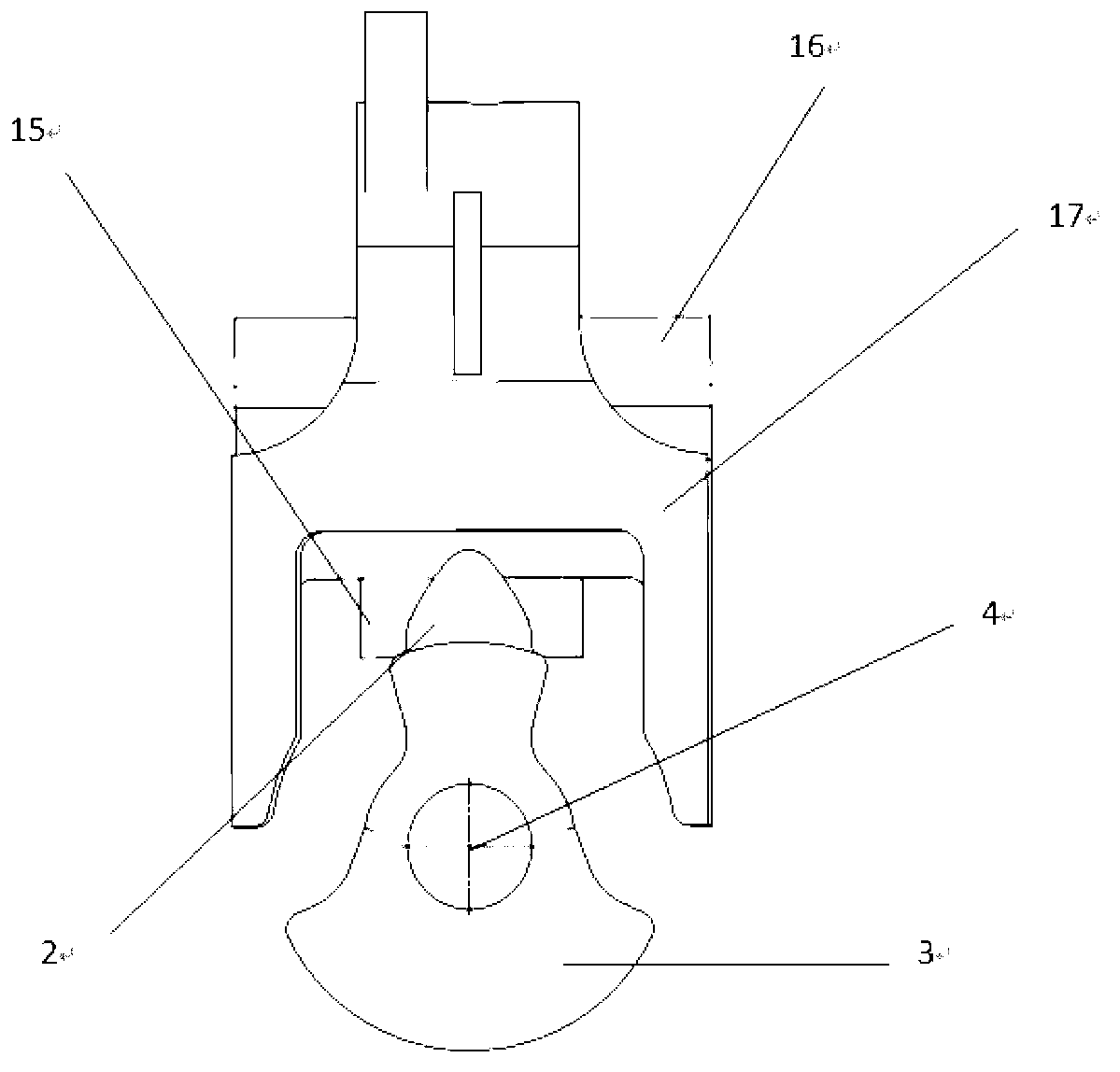

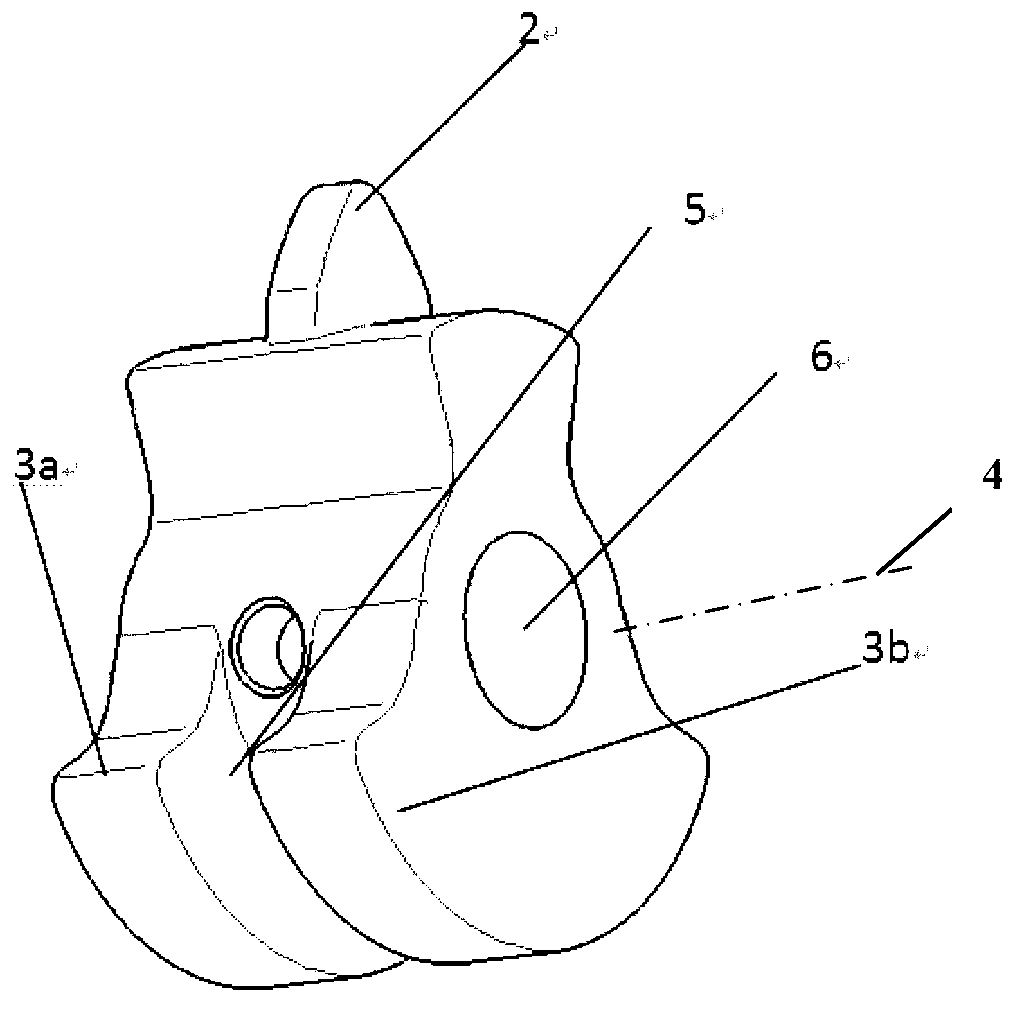

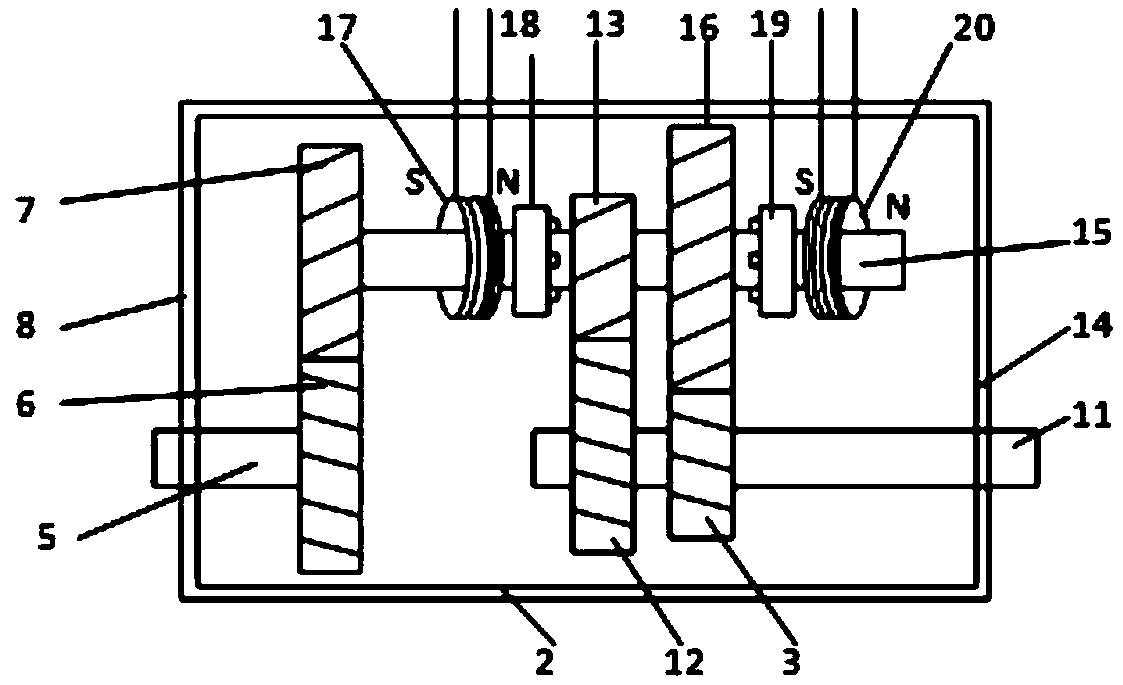

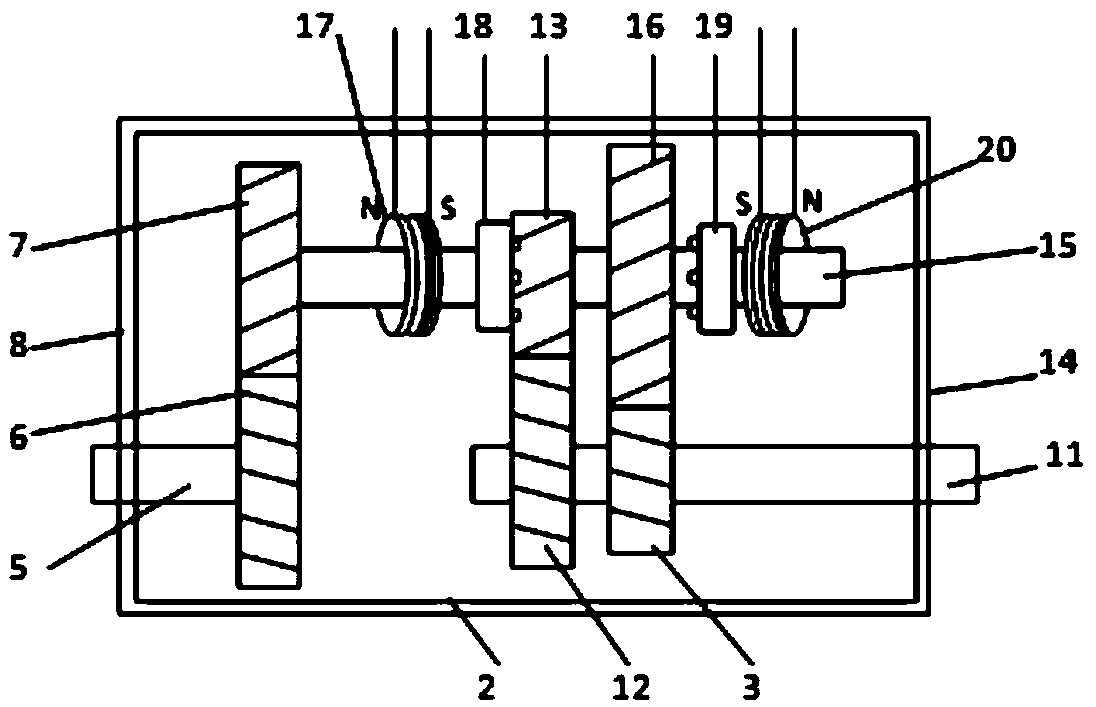

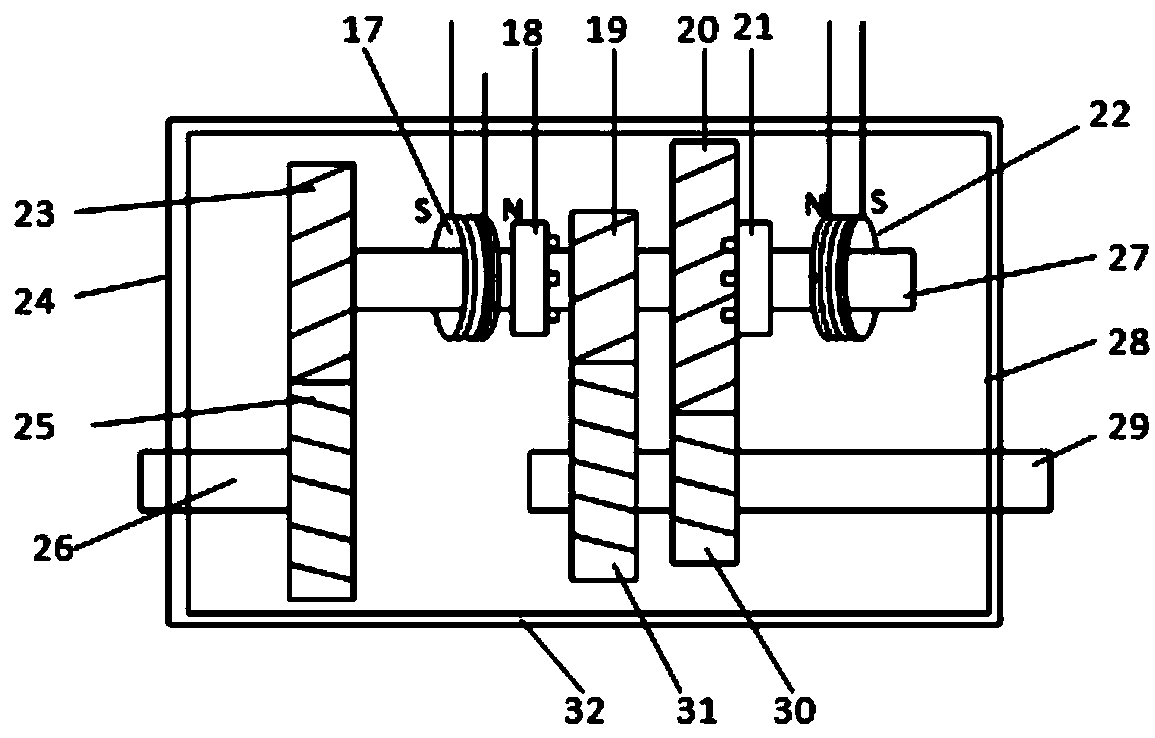

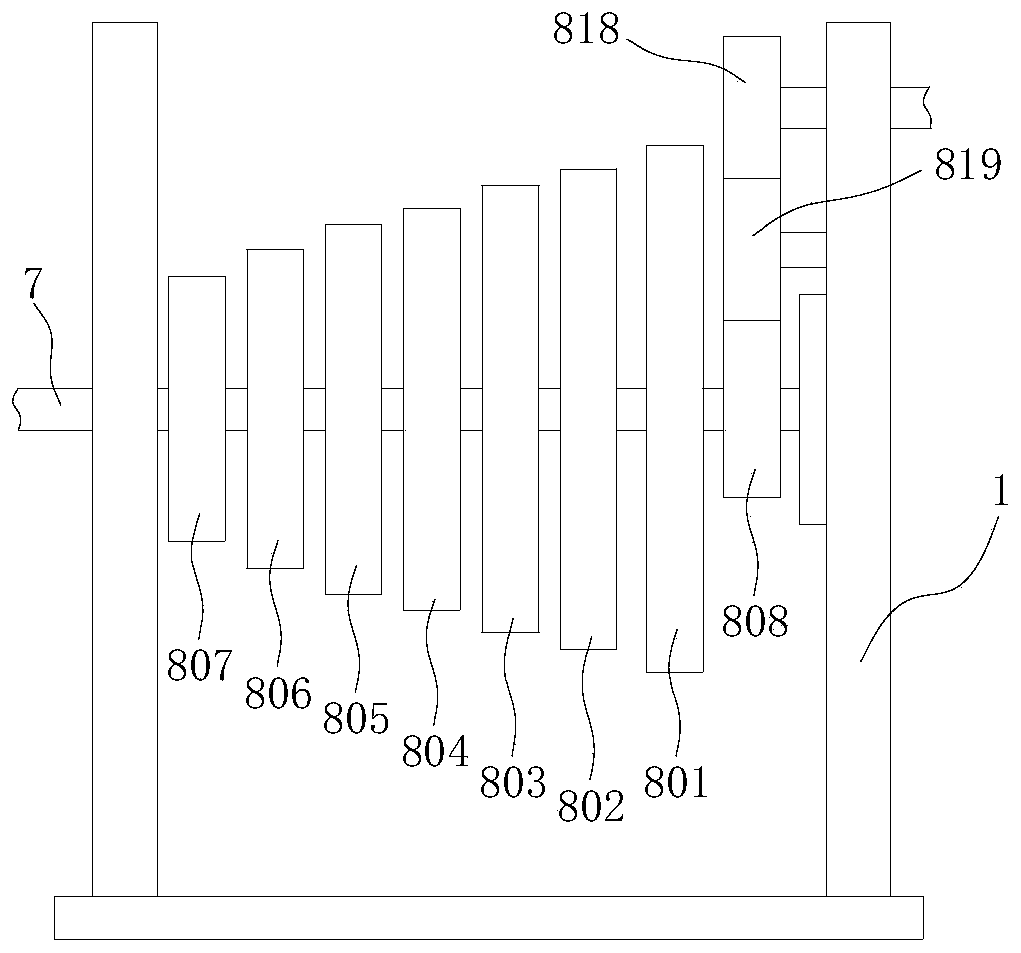

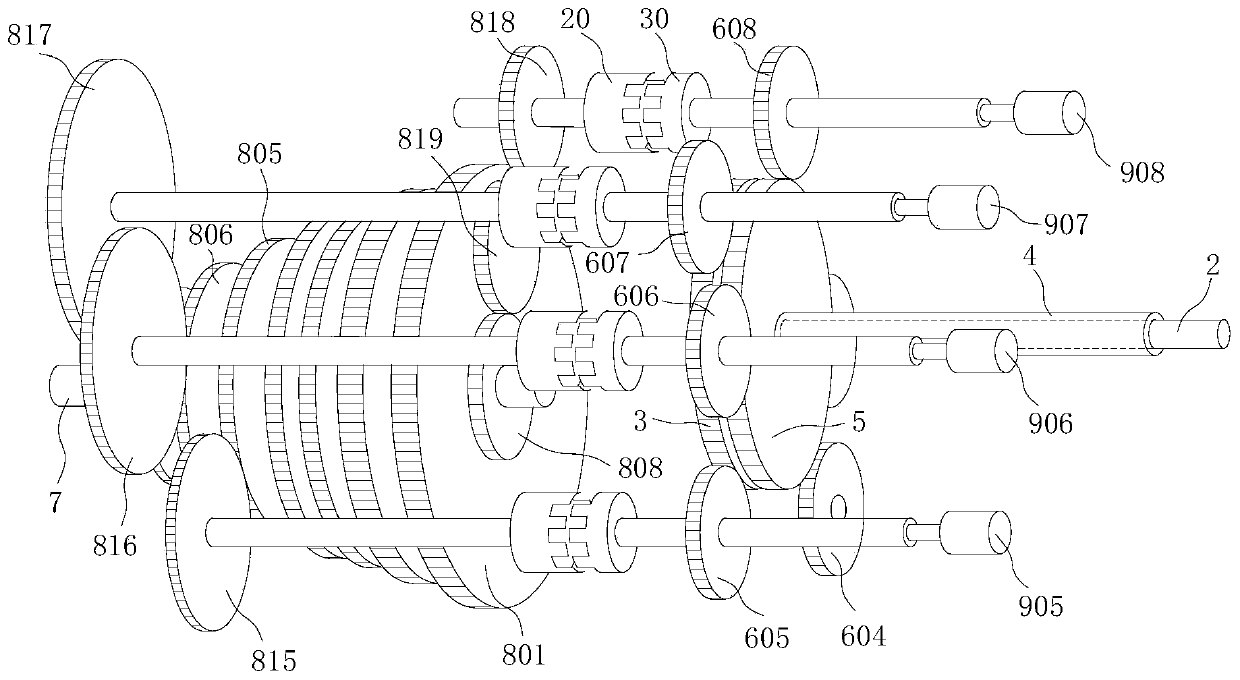

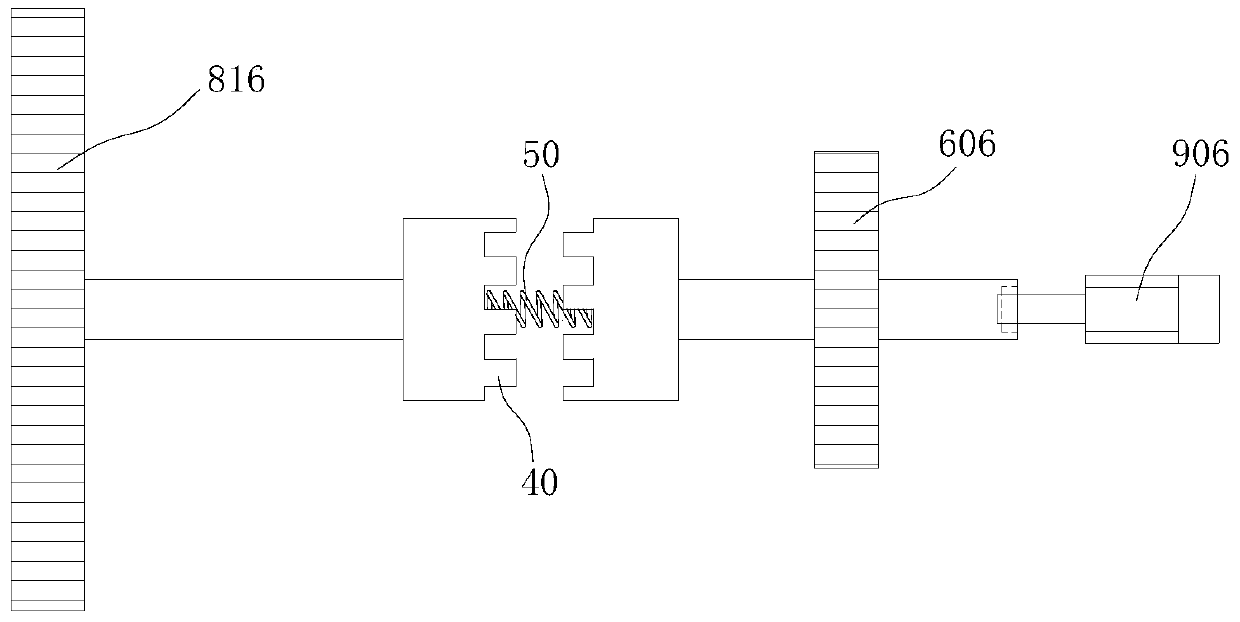

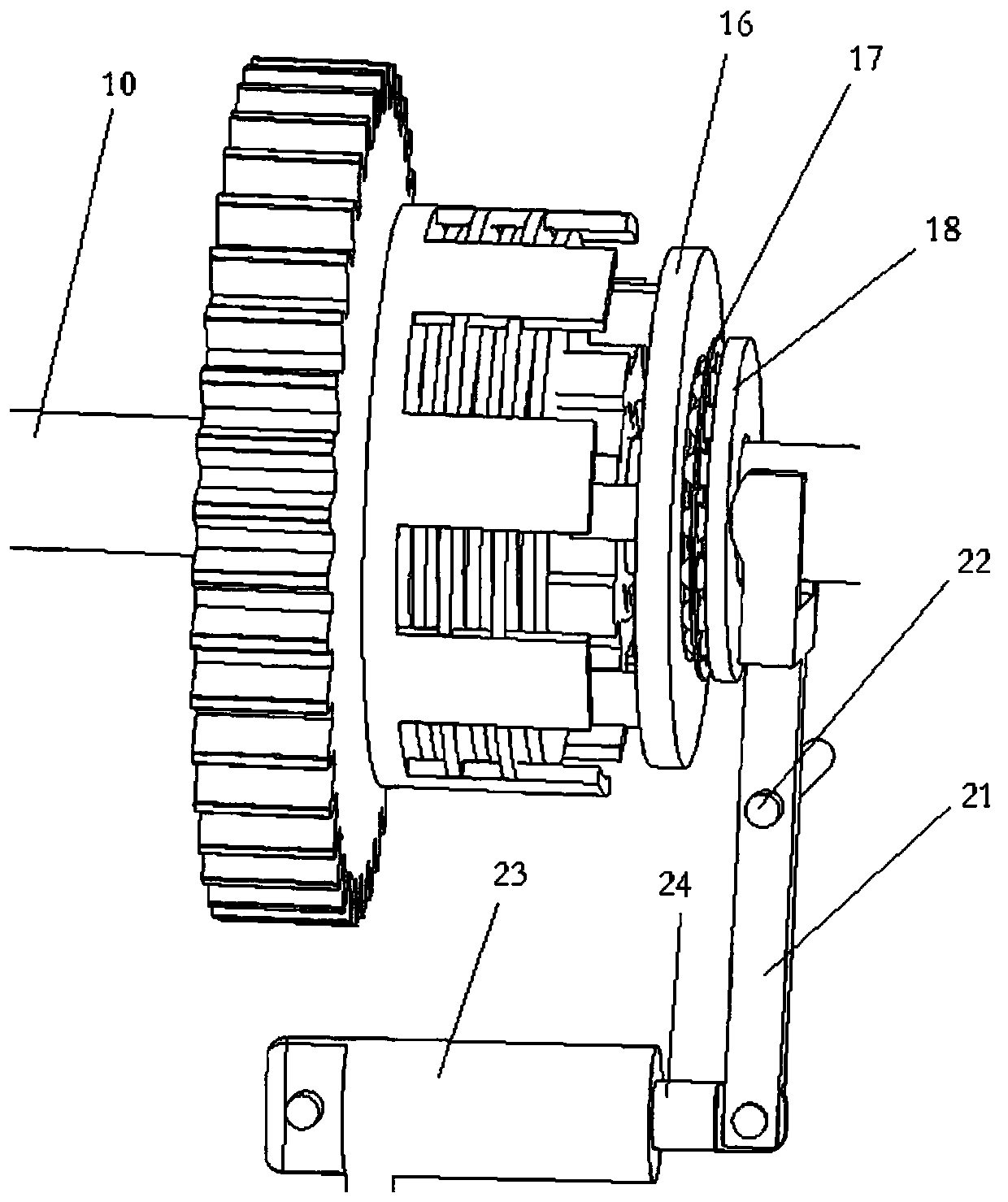

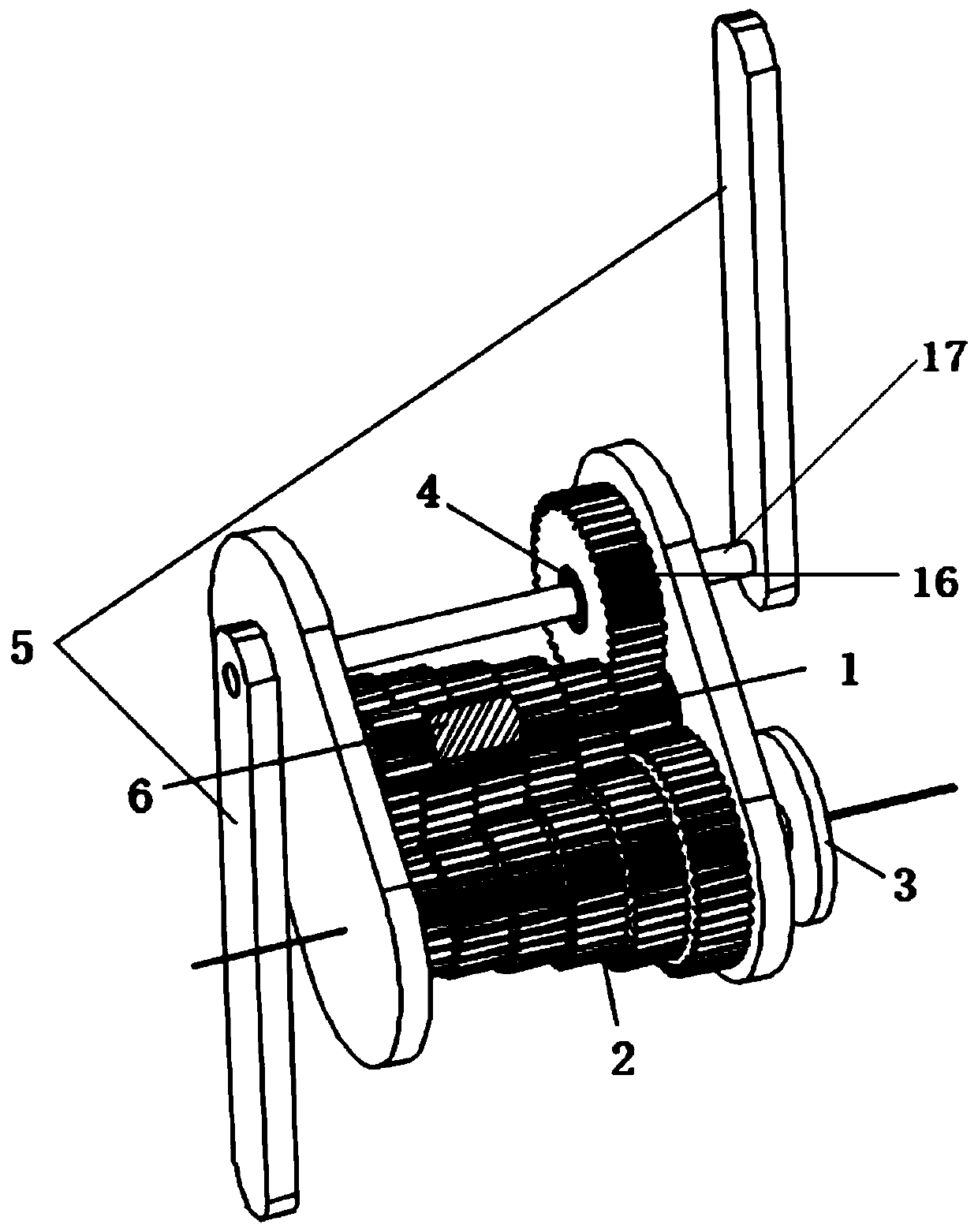

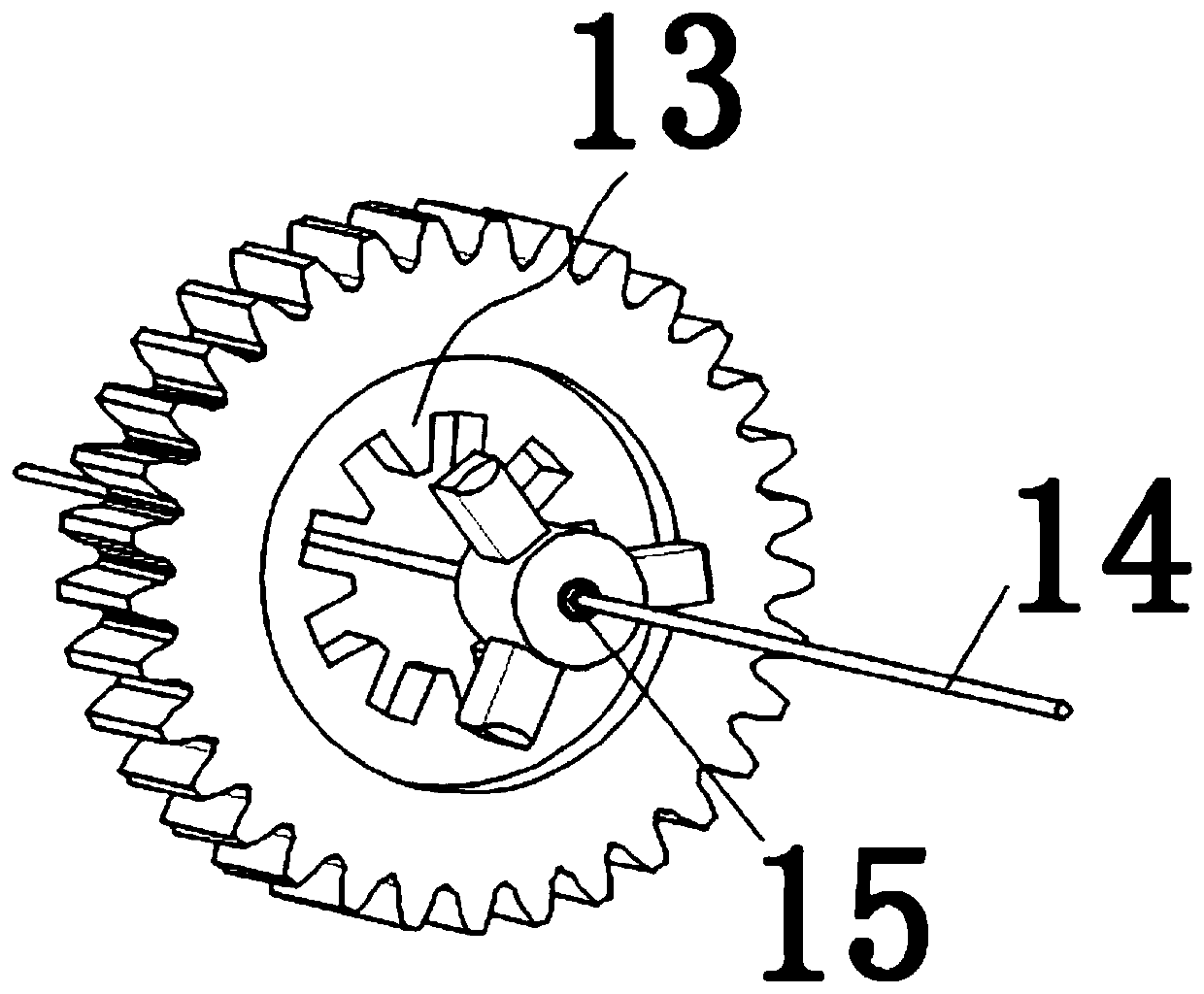

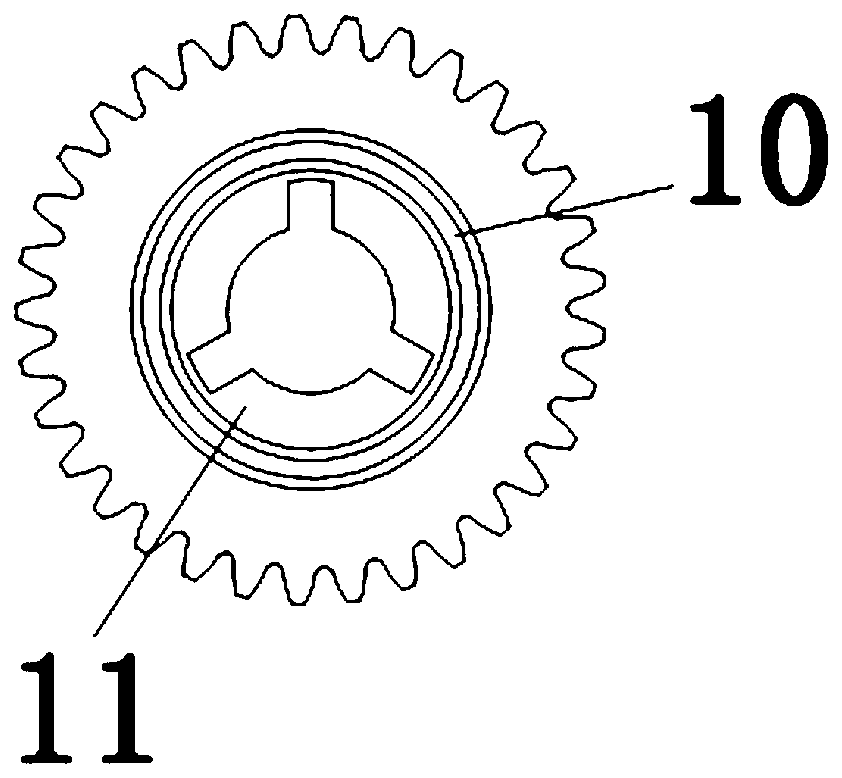

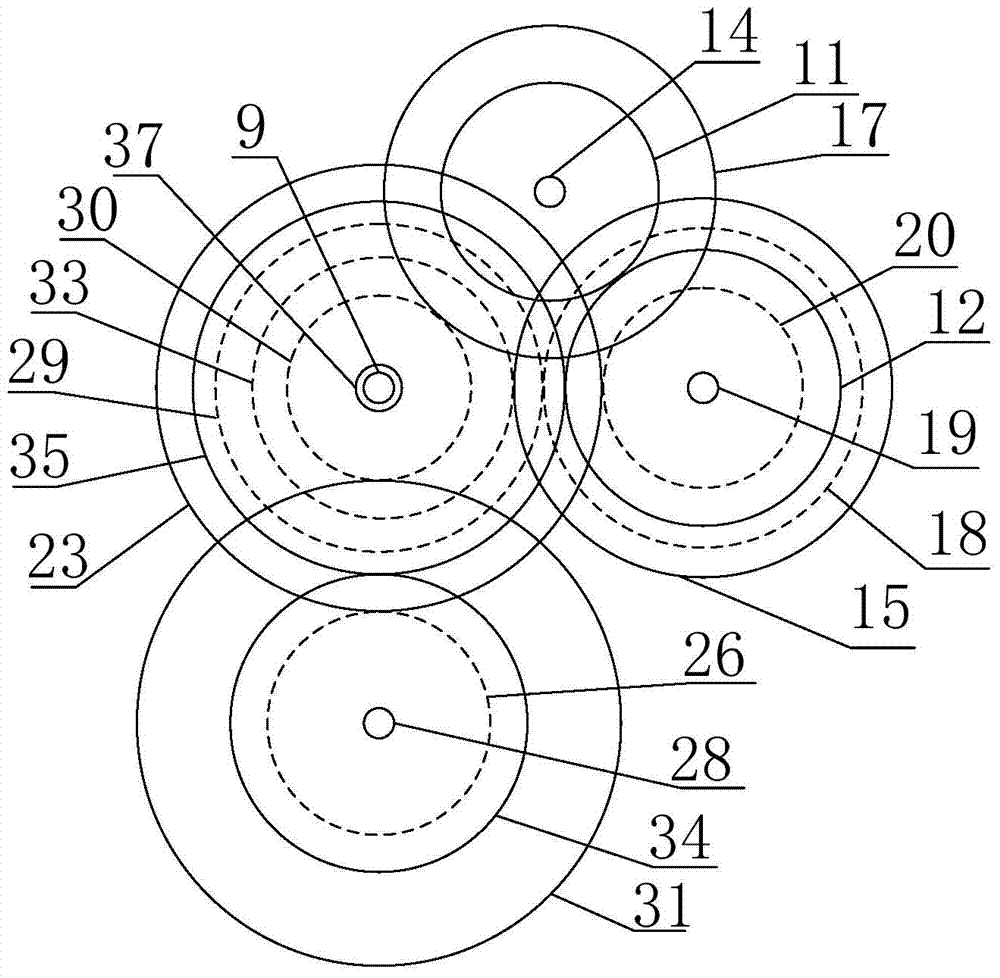

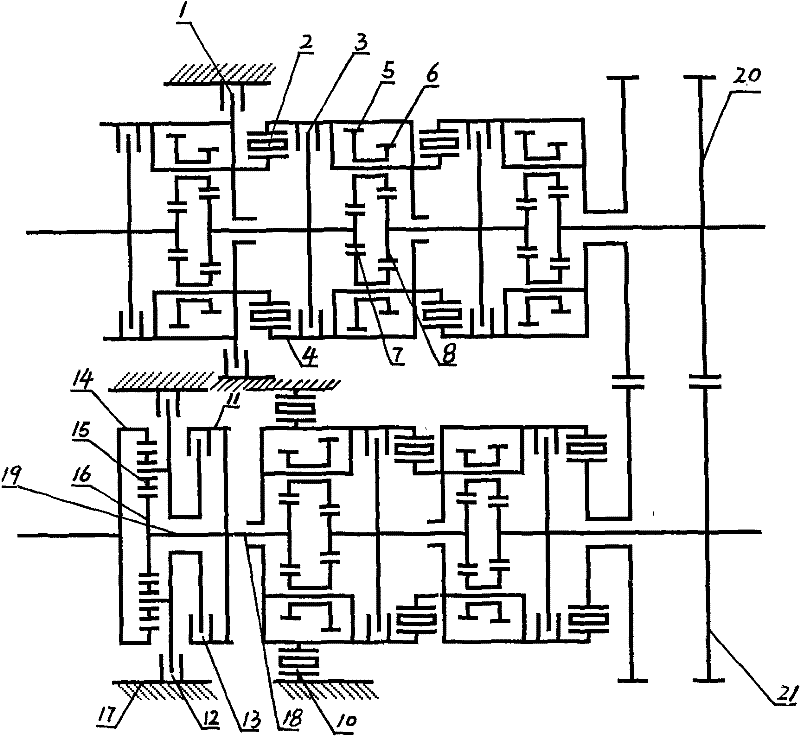

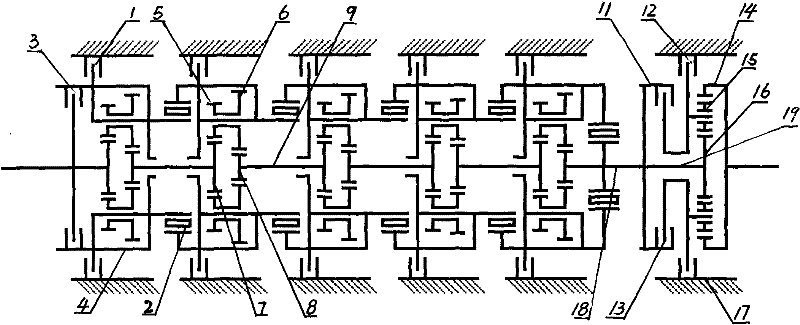

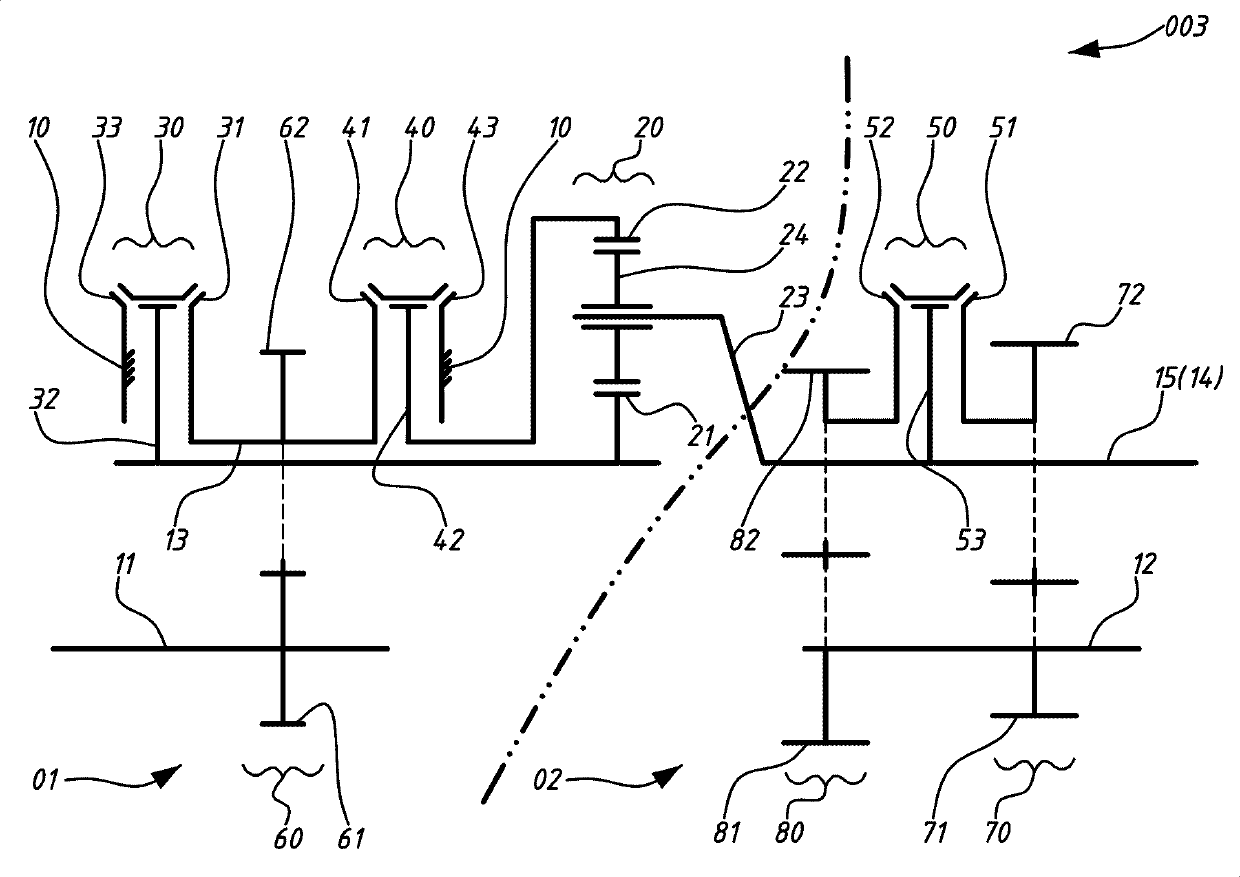

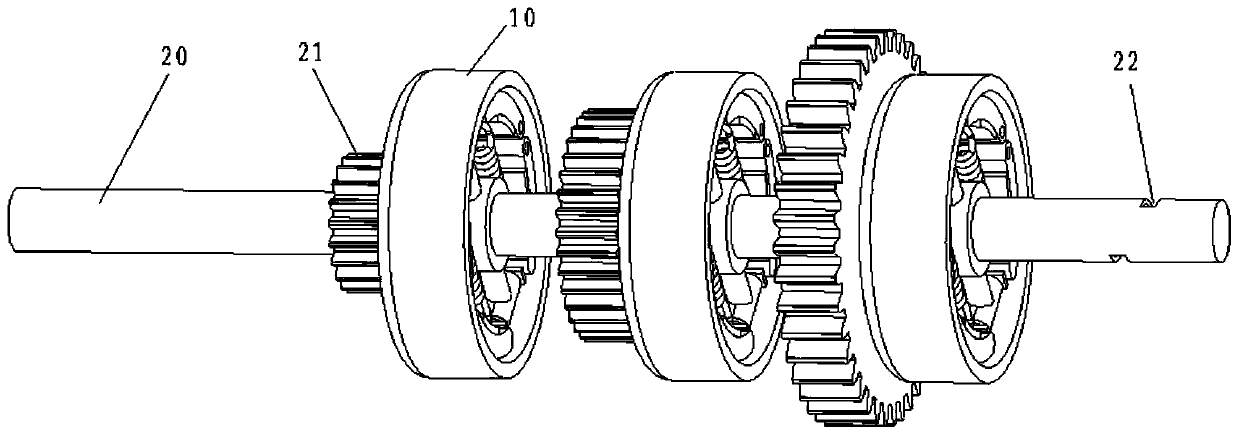

The invention relates to a planetary gearbox capable of directly shifting gears. A cylindrical principal planetary gear at the input end and a cylindrical principal planetary gear at the output end are installed on a planetary rotating shaft through a connection rotating shaft which are fixedly connected with the cylindrical principal planetary gears at the input end and the output end; the cylindrical principal planetary gear at the input end is meshed with a cylindrical sun gear at the input end; the cylindrical principal planetary gear at the output end is meshed with a cylindrical sun gear at the output end; and the planet carrier of the mth planetary transmission modular unit at the front-half transmission mechanism is matched and connected with the planet carrier of the (m+1)th planetary transmission modular unit at the rear-half transmission mechanism through a one-way clutch, or a driving gear fixed on the planet carrier of the mth planetary transmission modular unit and a driven gear fixed on the planet carrier of the (m+1)th planetary transmission modular unit form a mesh transmission. The planetary gearbox are formed by connecting independent planetary transmission modular unit mechanisms in series, can obtain a high transmission ratio, can directly shift gears, and has the advantages of simple structure, low manufacturing cost and easy maintenance.

Owner:陈国庆

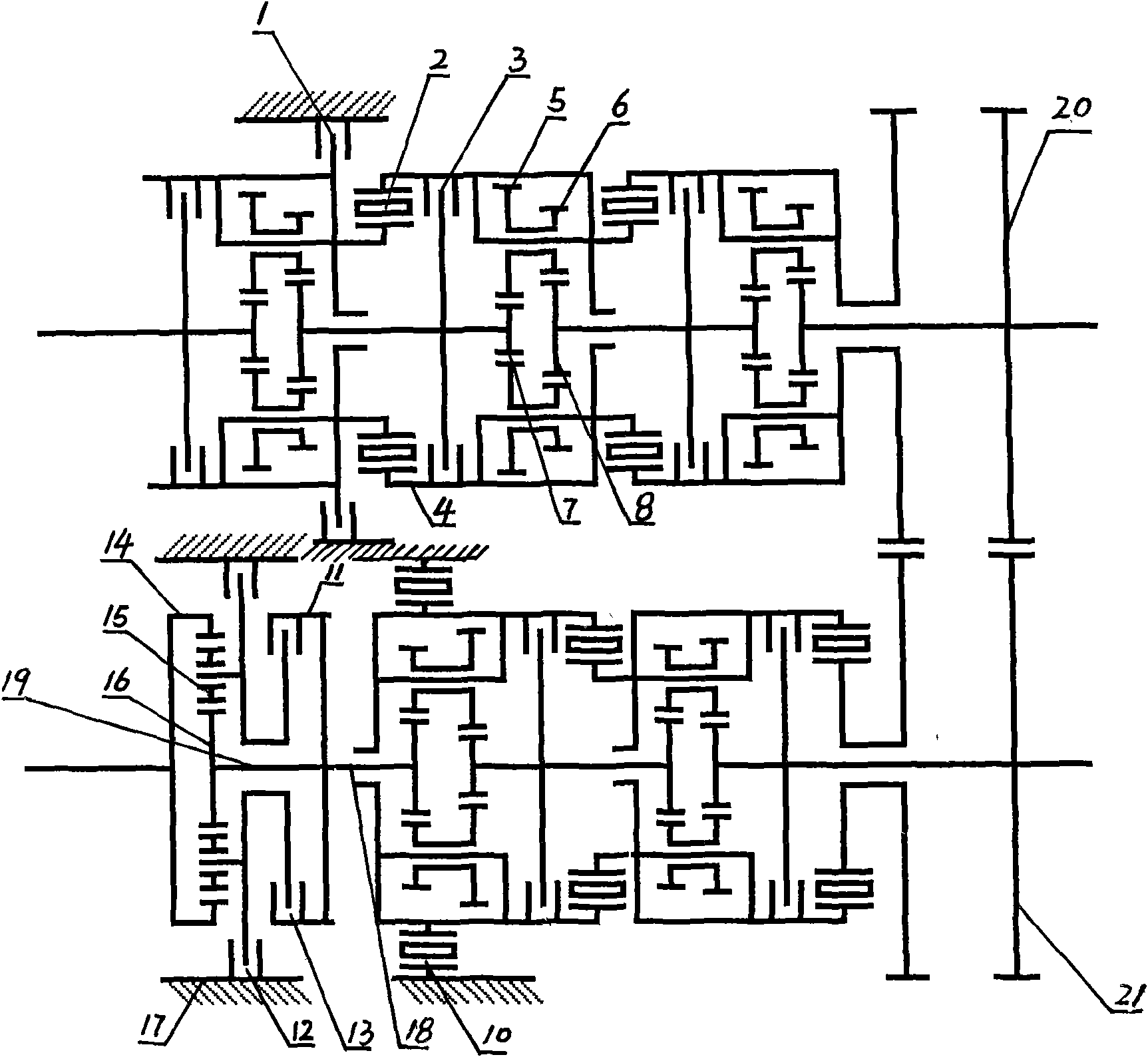

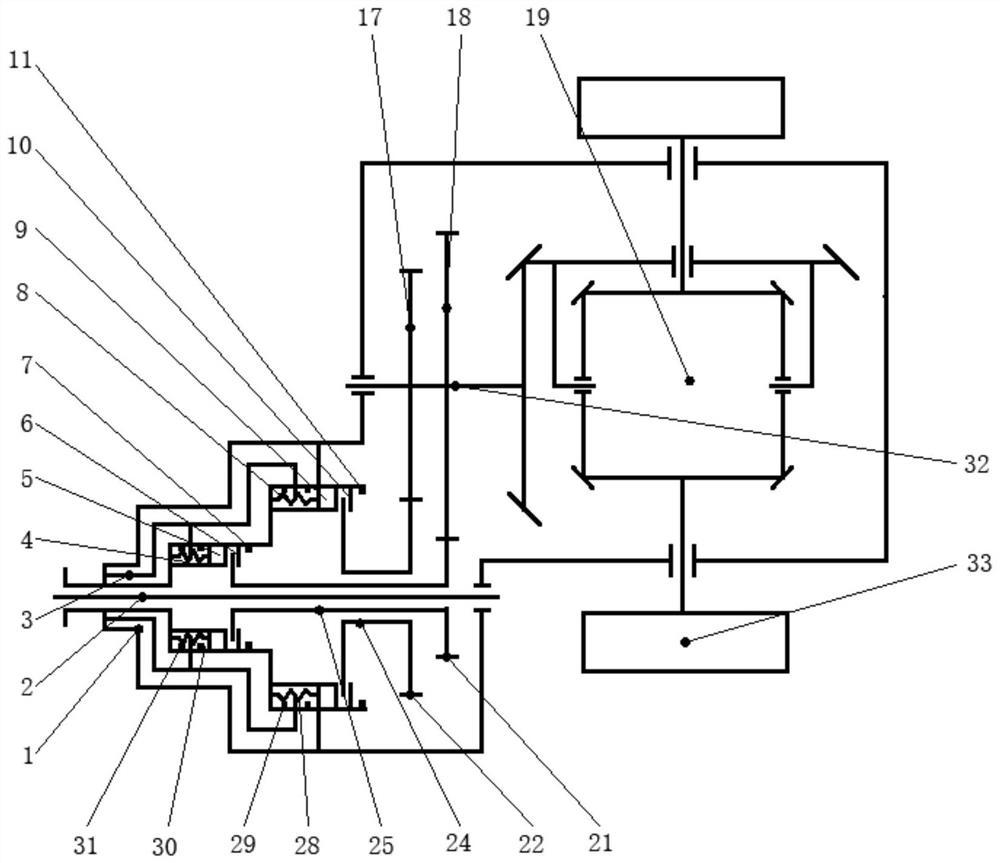

Hybrid driving system with three-clutch automatic transmission and control method thereof

InactiveCN104999902AImprove output efficiencyAdapt to the requirements of different power demandsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive motorVariator

The invention discloses a hybrid driving system with a three-clutch automatic transmission and a control method thereof. In order to solve a problem of the traditional hybrid driving system that total powers of an engine and a driving motor cannot be sufficiently utilized or the driving motor cannot always operate within an optimal output characteristic rotation speed range, the hybrid driving system with the three-clutch automatic transmission comprises a first power converter, a starter / generator integrated machine, an engine, a fourth clutch, a driving motor, an energy storage device, a second power converter, the three-clutch automatic transmission, a differential mechanism, a fourth clutch output shaft end gear, a driving motor output shaft end gear and a transmission input shaft end gear, wherein the transmission input shaft end gear is mounted on a transmission input shaft of the three-clutch automatic transmission; and the fourth clutch output shaft end gear, the driving motor output shaft end gear and the transmission input shaft end gear are engaged with each other in sequence. The invention further provides a control method for the three-clutch automatic transmission.

Owner:JILIN UNIV

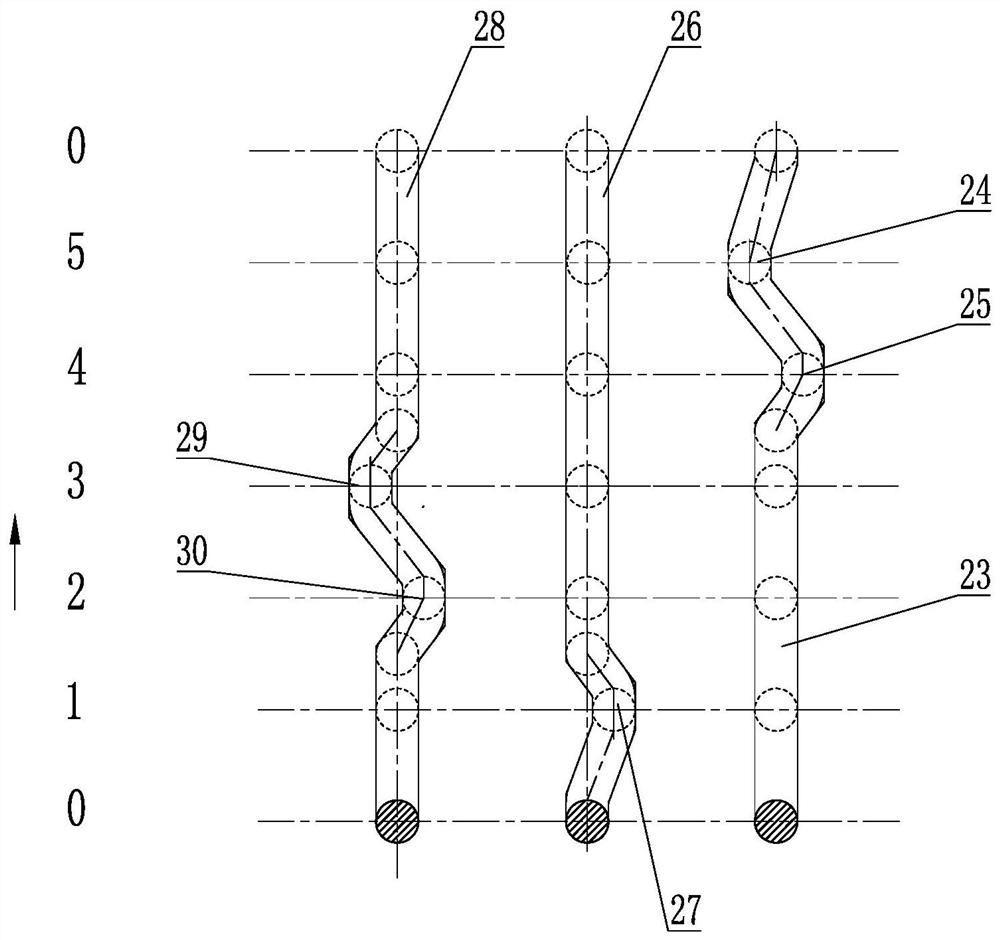

Automatic manual speed changer and speed change control mechanism thereof

InactiveCN103867709ASimple structureWork reliablyControlled membersGearing controlEngineeringChange control

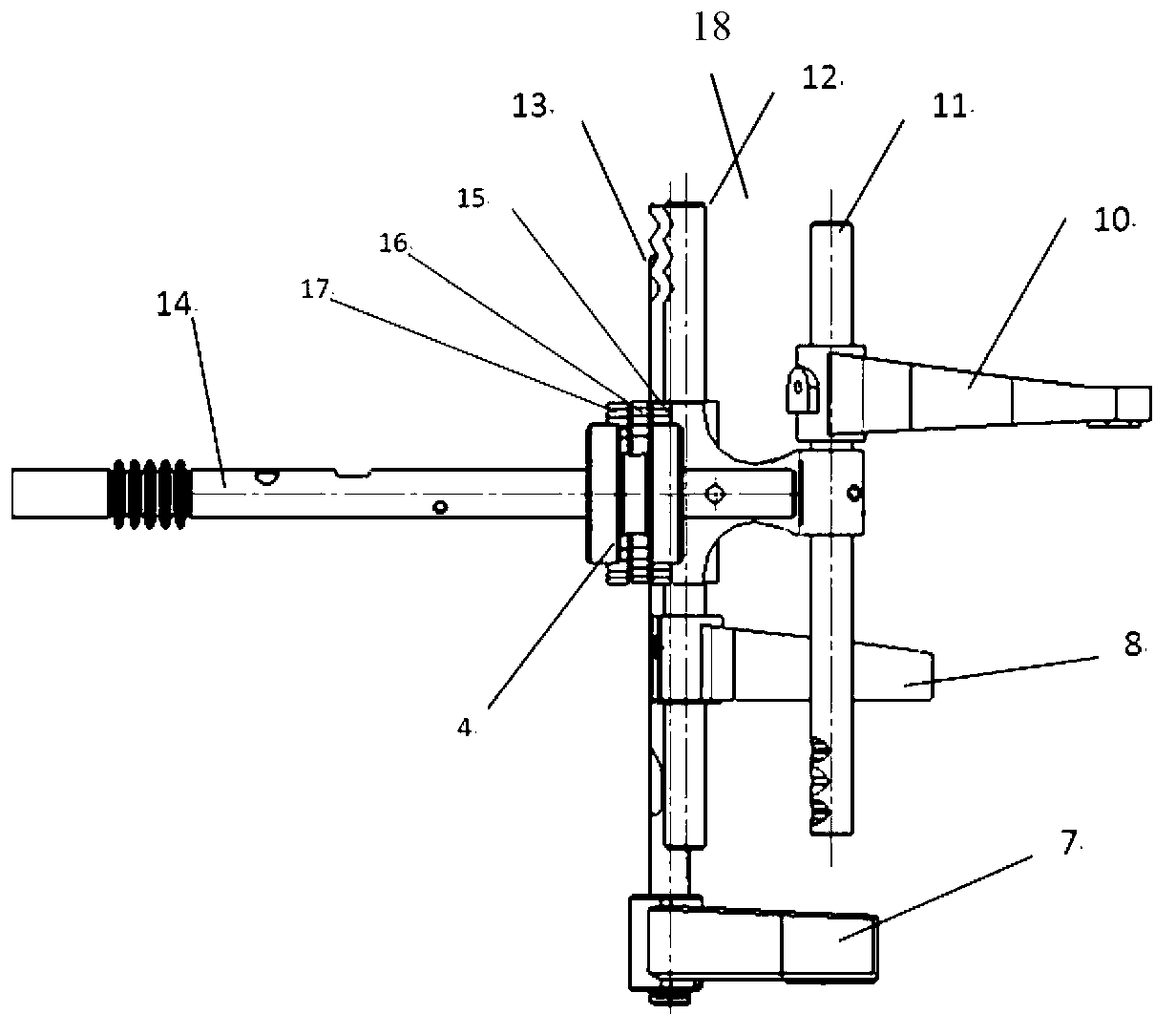

The invention relates to an automatic manual speed changer and a speed change control mechanism thereof. The speed change control mechanism of the automatic manual speed changer comprises N gear shift fork components, a rotation drum which can rotate around the longitudinal axis and is provided with an endless annular groove around the peripheral face of the rotation drum, and gear shift deflector rods with first ends and second ends, wherein the number N of the gear shift fork components is larger than or equal to 2, the groove comprises N segments constant in height, which are different in constant radial height, and segments gradually varied in height, which are spliced with the adjacent segments constant in height, at least a part of the segments constant in height are in S shape and all the segments gradually varied in height are in collinear straight line shape and vertical to the longitudinal axis of the rotation drum when looked at from an expanded view of the peripheral face of the rotation drum, the first ends of the gear shift deflector rods are sequentially connected with the N segments constant in height in sliding mode, the gear shift deflector rods pivot so as to connect the second ends of the gear shift deflector rods with the N gear shift fork components in sequence, the first ends of the gear shift deflector rods are joined with the S-shaped portions of all the segments constant in height so as to enable the gear shift deflector rods to swing back and forth and enable the second ends of the gear shift deflector rods to drive the conterminal gear shift fork components to move back and forth once, and accordingly the automatic manual speed changer is enabled to sequentially achieve at most 2N gears for transmitting machinery force.

Owner:EATON CORP

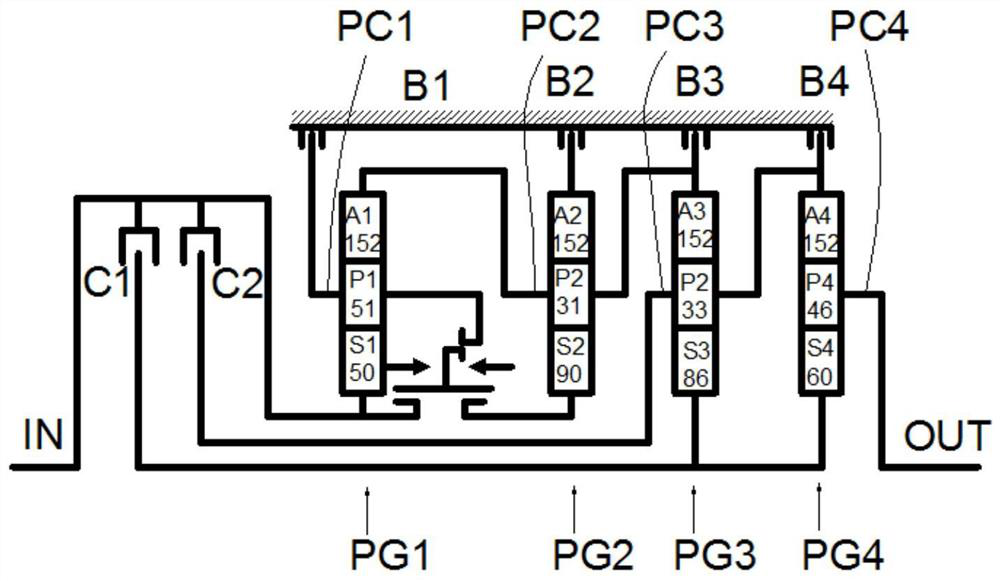

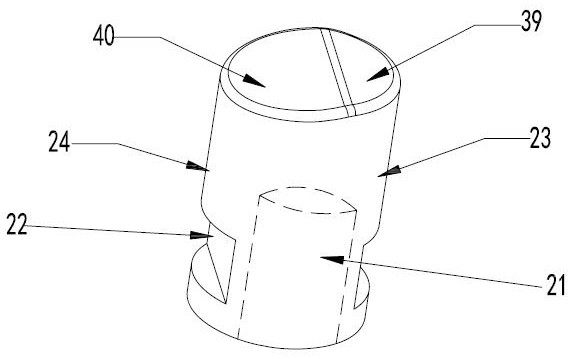

Shift control mechanism of transmission

InactiveCN103062385AImplement Shift InterlockDoes not affect the push-in functionGearing controlService efficiencyCam

The invention relates to a shift control mechanism of a transmission. The shift control mechanism comprises a first shift lever, a second shift lever, a third shift lever and a fourth shift lever, wherein a first shift fork and a first shift drive fork are matched on the upper portion of the first shift lever, a second shift fork and a second shift drive fork are matched on the lower portion of the second shift lever, the lower portions of the third shift lever and the fourth shift lever are matched with a third shift drive fork respectively, and a third shift fork is matched on the upper portion of the fourth shift lever. The shift control mechanism is characterized in that a shift block is composed of a shift finger and a shift cam, a mounting hole is arranged at the center of the shift cam, a shift shaft is perpendicular to the fourth shift lever and matched with the mounting hole on the shift cam, and the shift finger is positioned between inner sides of the first shift fork, the second shift fork and the third shift fork. The shift control mechanism is simple in structure, and capable of achieving shift interlocking and gear selection before dislocating, reducing shift time, and improving safety and service efficiency of the transmission.

Owner:CHONGQING TSINGSHAN IND

Gearbox

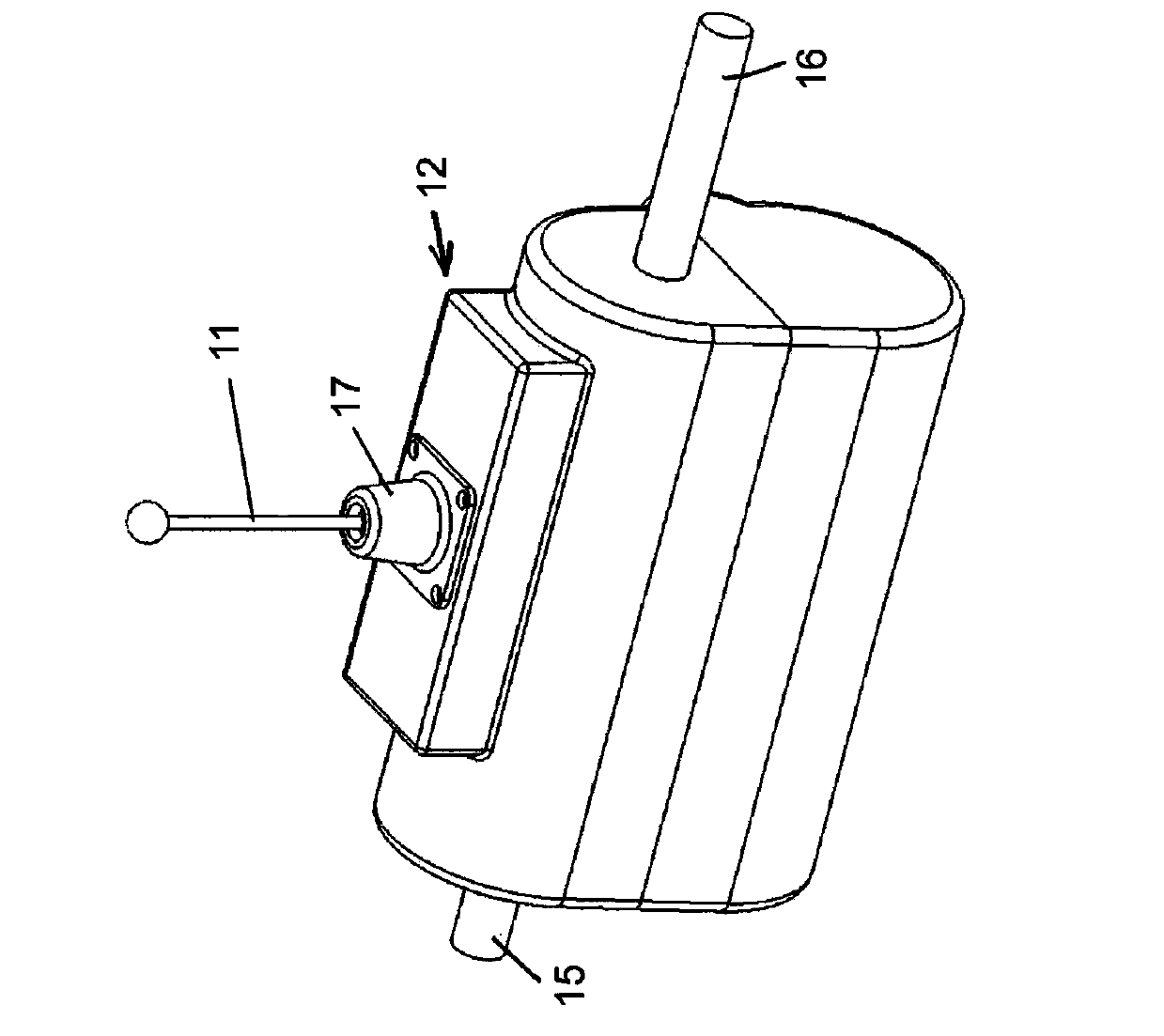

PendingCN109210177ASimple structureReduce friction lossGearing controlGearing detailsGear wheelFriction force

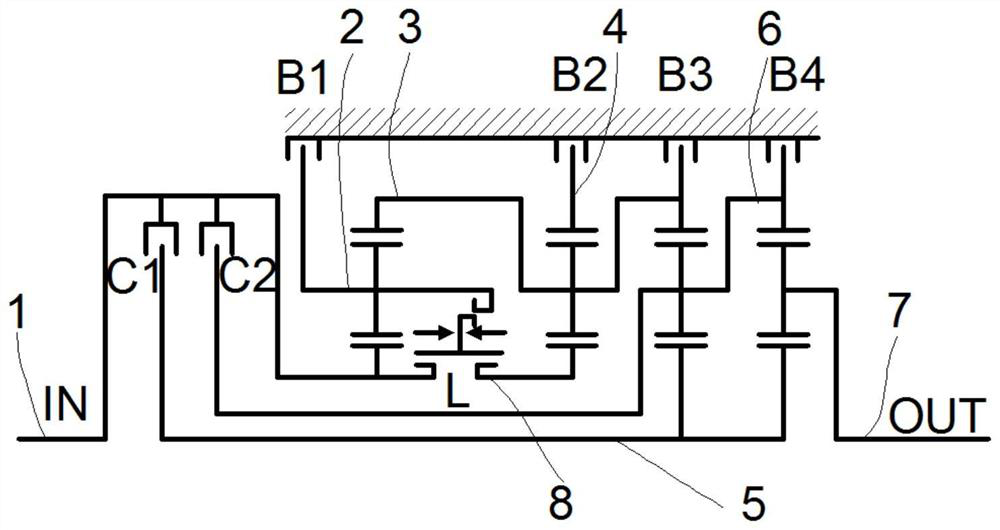

The invention discloses a gearbox. The gearbox comprises a gearbox casing, a power input shaft, an intermediate shaft and a power output shaft are arranged in the gearbox casing in a penetrated way, and each gear on the intermediate shaft is engaged with a gear on the power input shaft or gears on the power output shaft; the intermediate shaft is provided with first and second solenoids, a synchronizer is arranged between the first solenoid and the small gear of the intermediate shaft, and another synchronizer is arranged between the second solenoid and the large gear of the intermediate shaft; the gearbox casing, the power input and output shafts, the intermediate shaft and all the gears are made of non ferromagnetic materials, the synchronizers are made of permanent magnets, and the first and second solenoids control the synchronizers to move on the intermediate shaft; and a switching circuit which controls the current magnitudes and directions of the first and second solenoids is arranged outside the gearbox casing. The gearbox casing solves the problems that a present gearbox is complex in mechanical structure, large in friction force, easy to damage and not durable, and the service life of different components can be prolonged.

Owner:农初杰

Automatic manual speed changer and speed change control mechanism thereof

The invention relates to an automatic manual speed changer and a speed change control mechanism thereof. The speed change control mechanism of the automatic manual speed changer comprises N gear shift fork components, a rotation drum which can rotate around the longitudinal axis and forms an endless annular groove located around the peripheral face of the rotation drum, and N gear shift deflector rods with first ends and second ends, wherein the number N of the gear shift fork components is larger than or equal to 1, the groove comprises a linear segment which seems vertical to the longitudinal axis of the rotation drum when a person looks at an expanded view of the peripheral face of the rotation drum, and an S-shaped segment which is spliced with the linear segment and in S shape in the expanded view, the whole of the groove is the S-shaped segment when the N is equal to 1, the first ends of the gear shift deflector rods are connected with the side face of the groove in sliding mode, the second ends of each gear shift deflector rod is connected with a gear shift fork component in operation mode, the first ends of the N gear shift deflector rods are sequentially and independently connected with the S-shaped segment of the groove in sliding mode so as to enable the N gear shift deflector rods to sequentially swing back and forth and enable the second ends of the N gear shift deflector rods to drive the N gear shift fork components to move back and forth, and accordingly the automatic manual speed changer is enabled to sequentially obtain at most 2N gears for transmitting machinery force.

Owner:EATON CORP

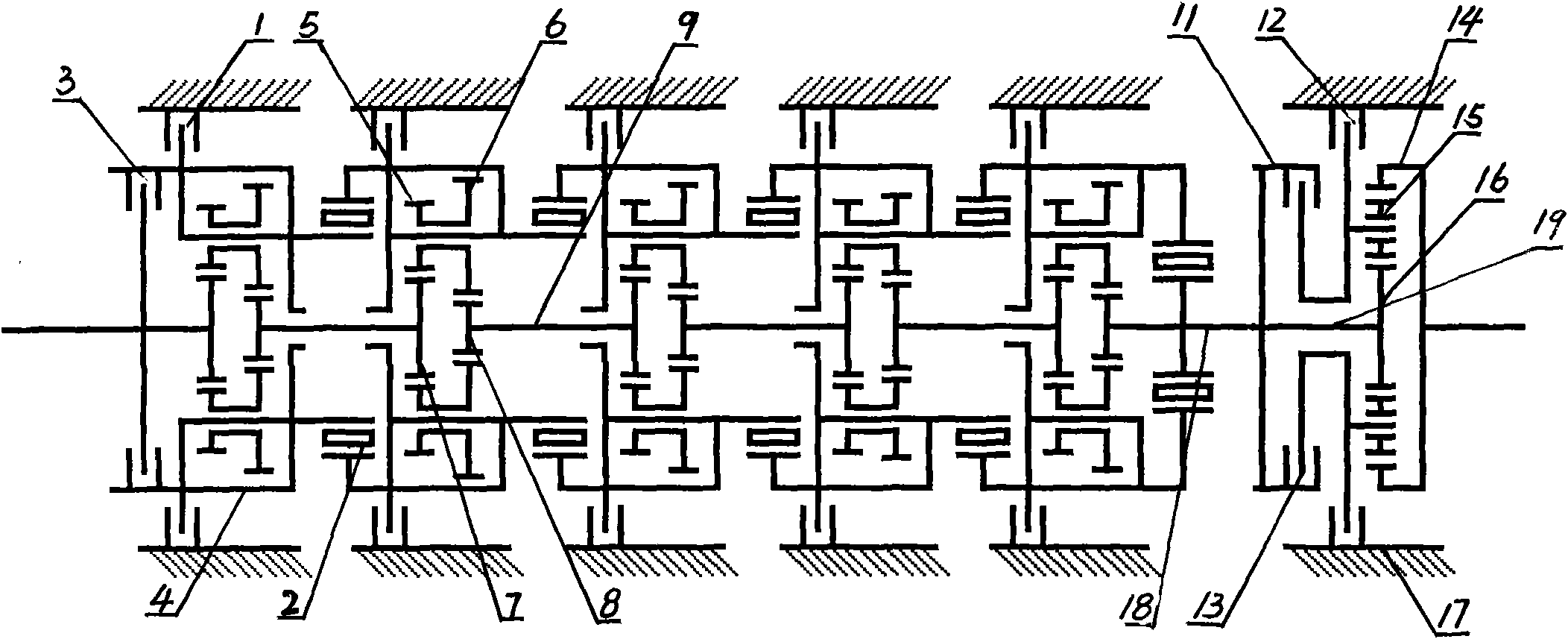

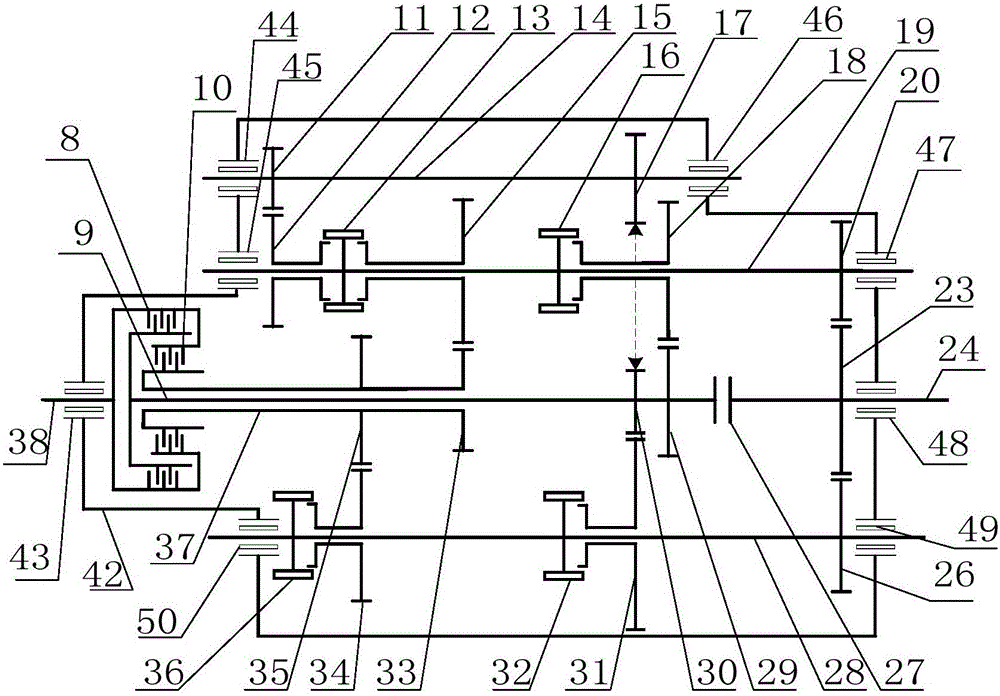

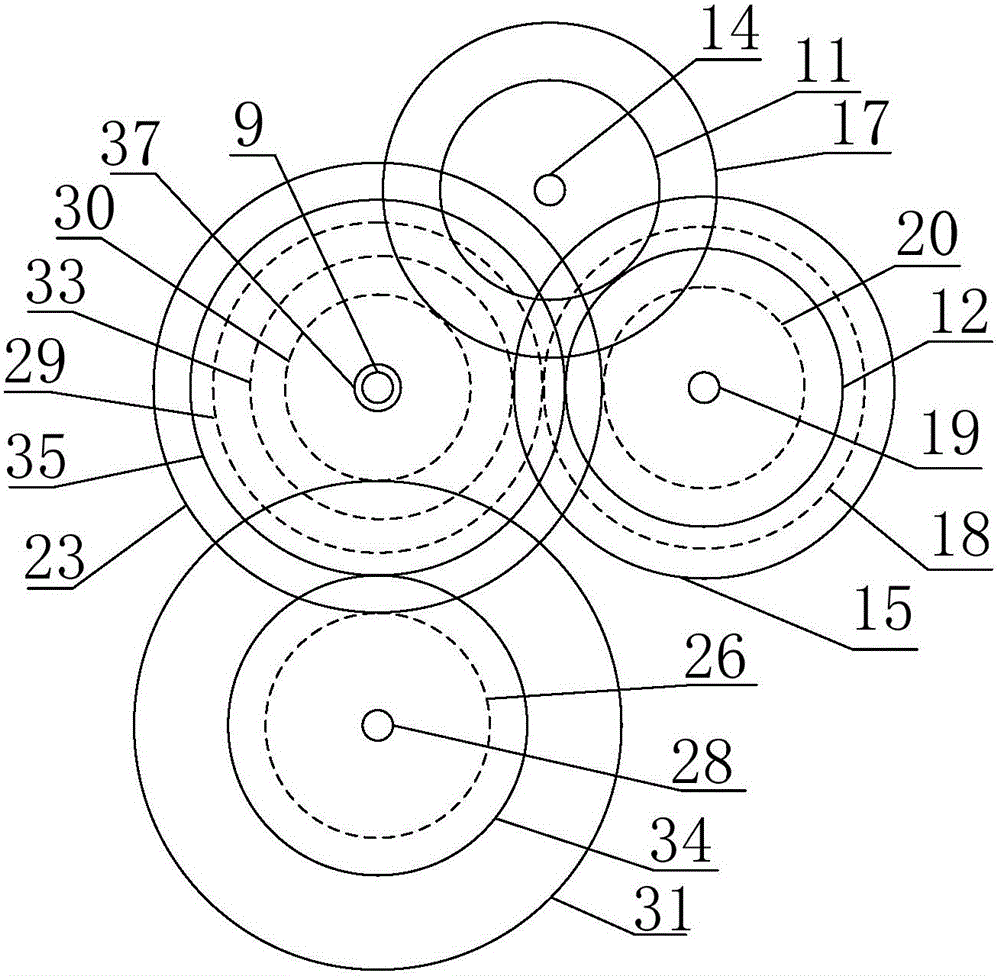

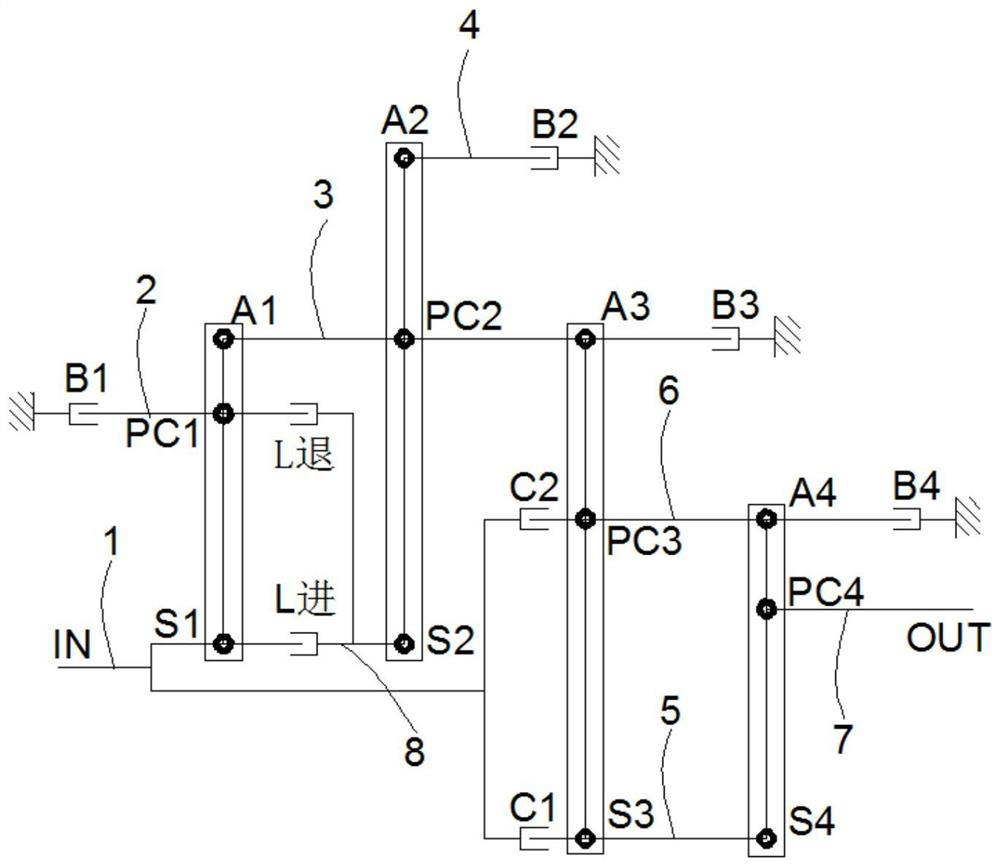

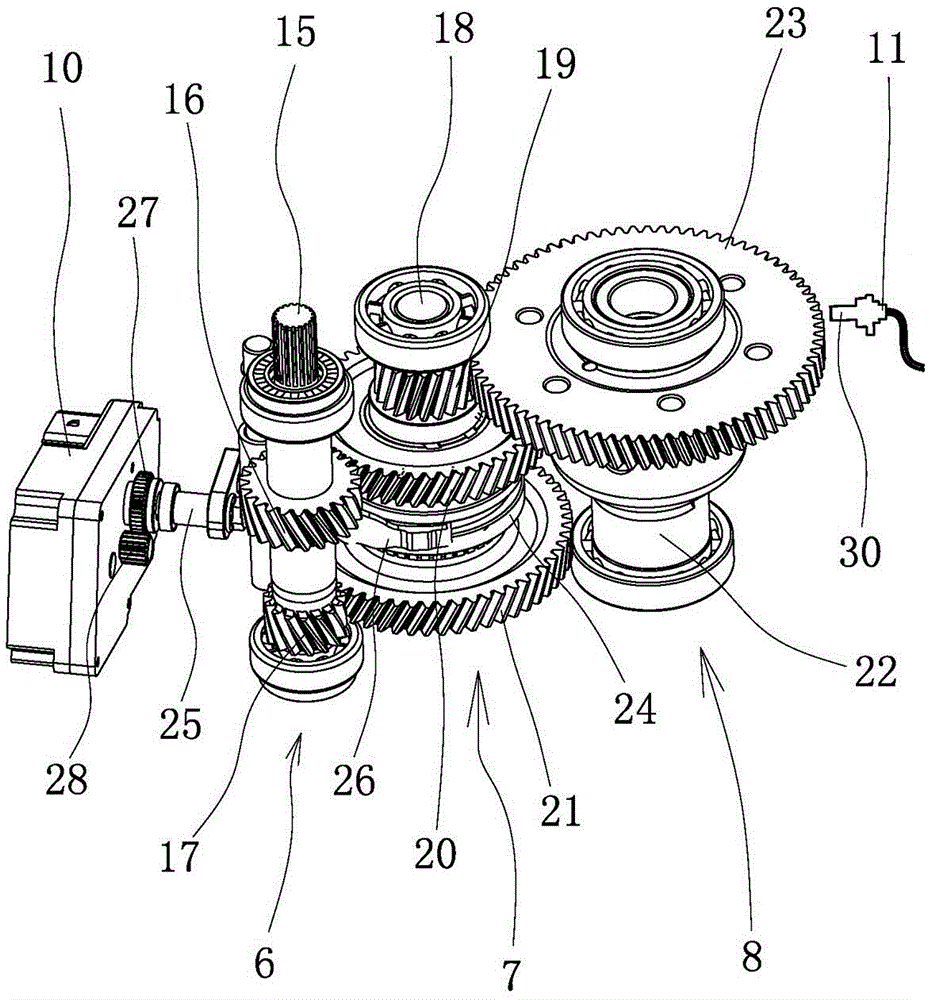

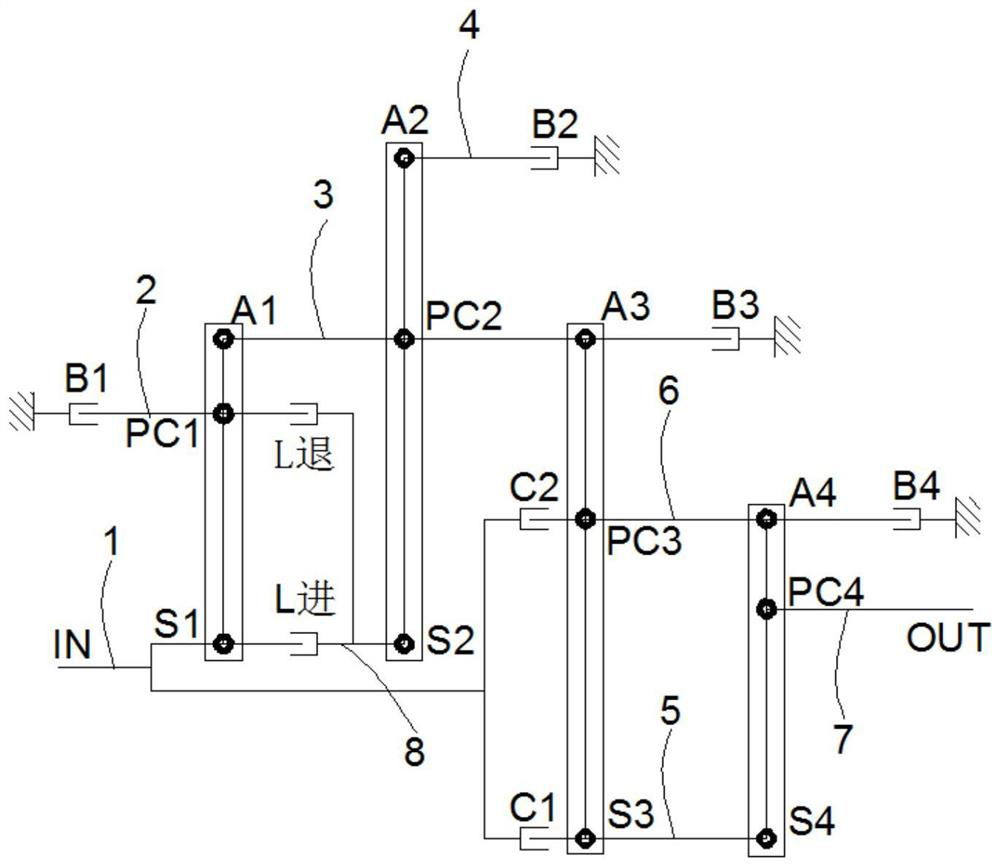

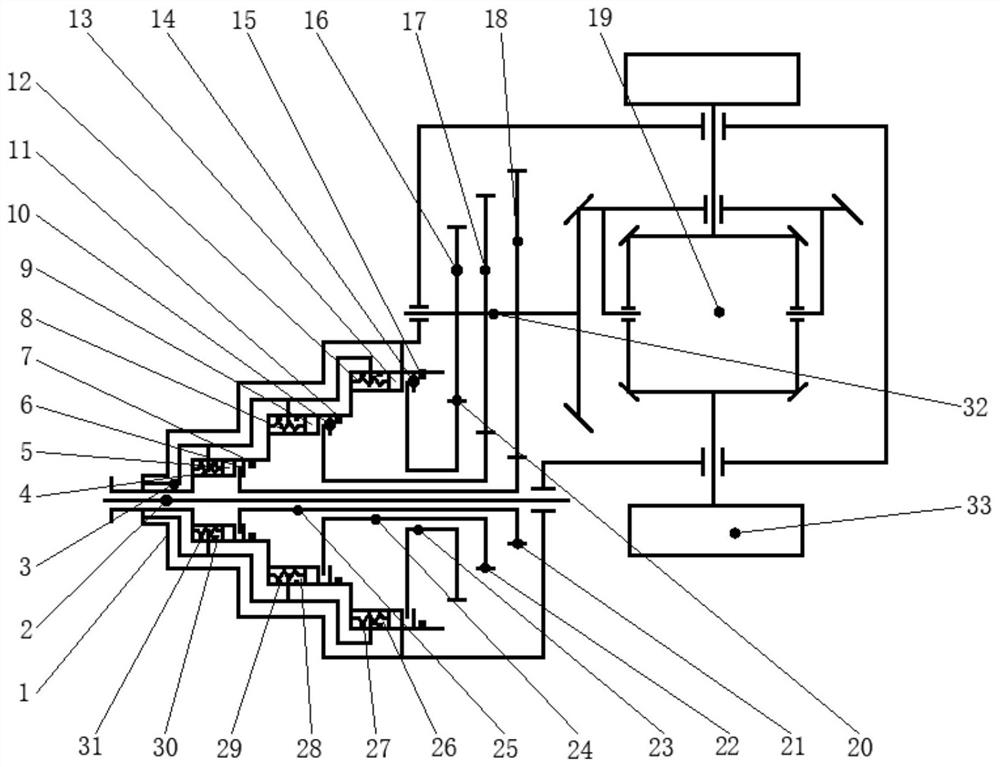

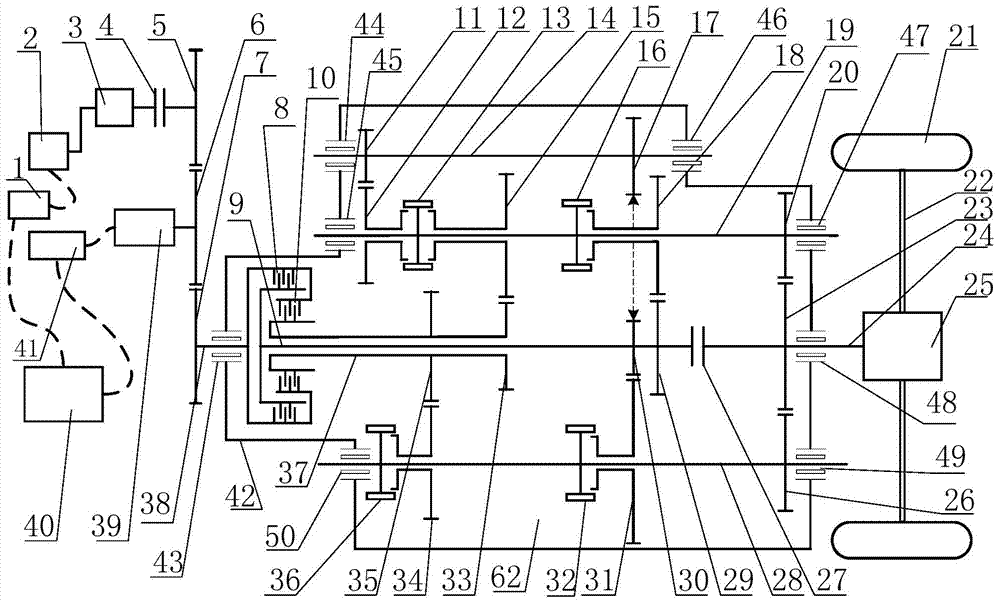

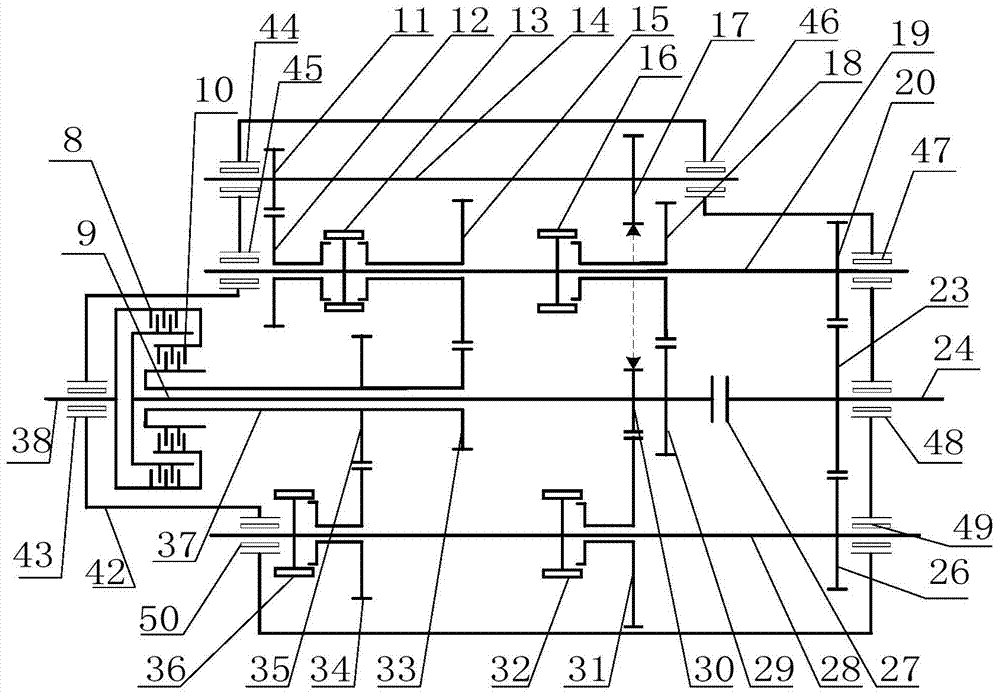

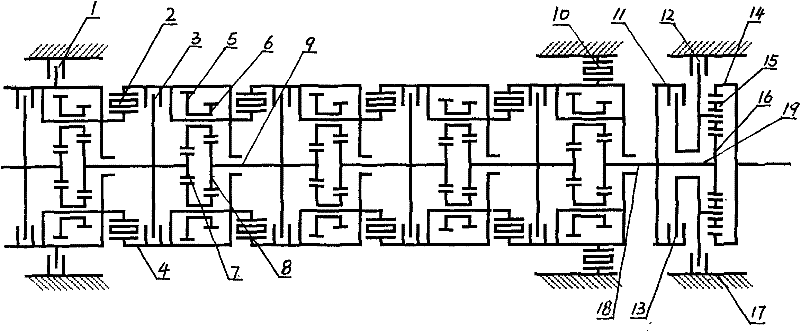

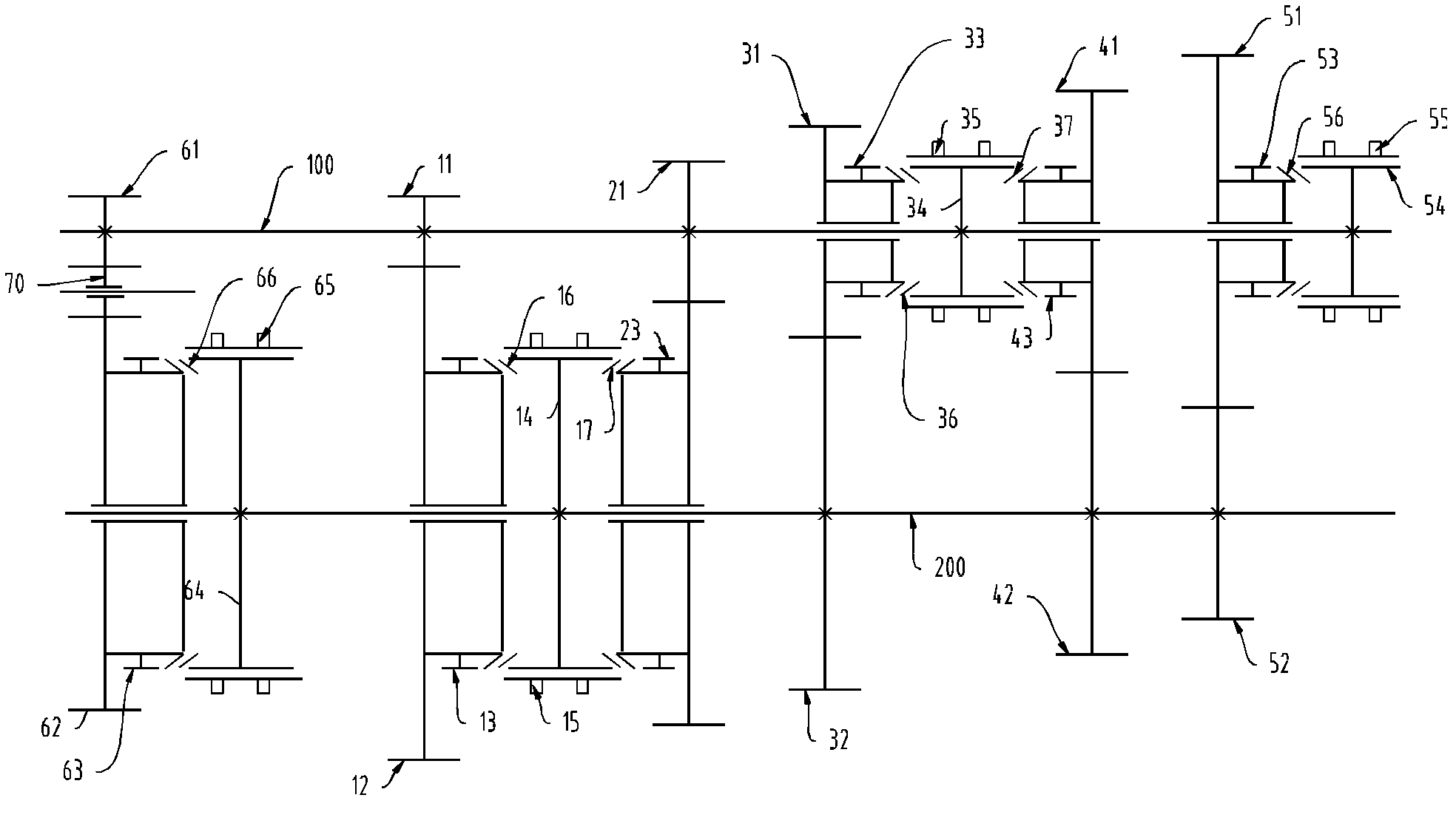

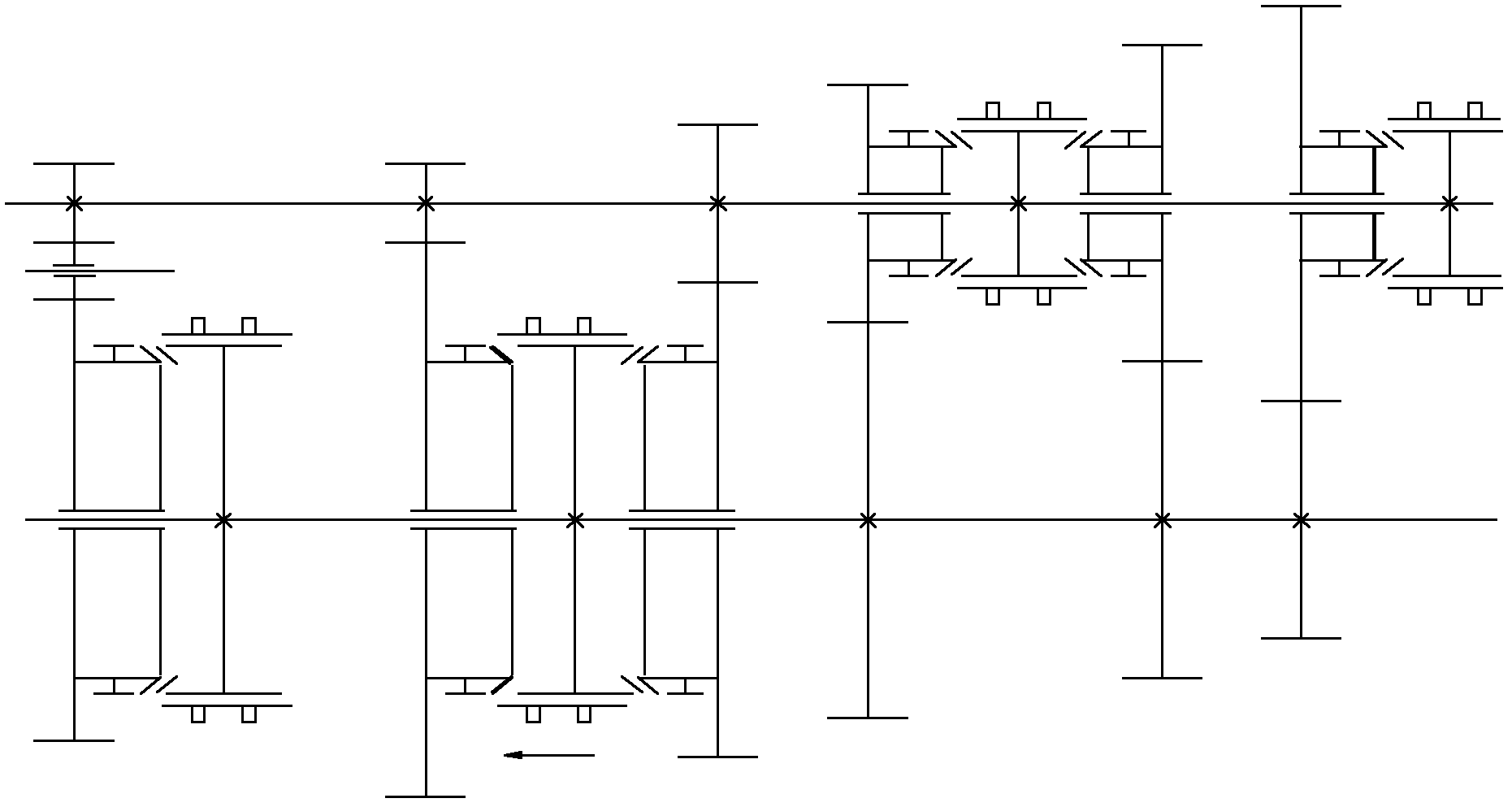

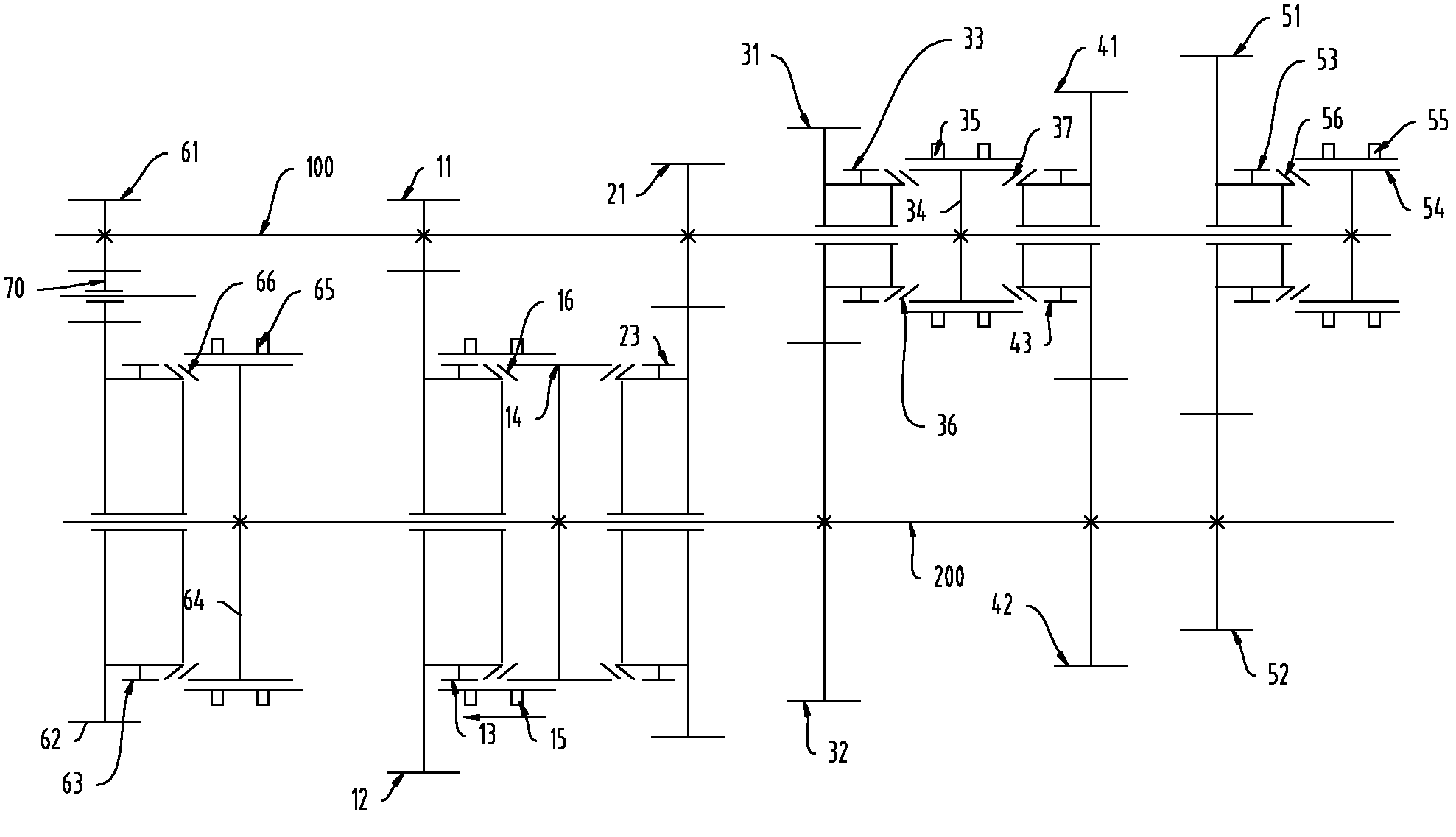

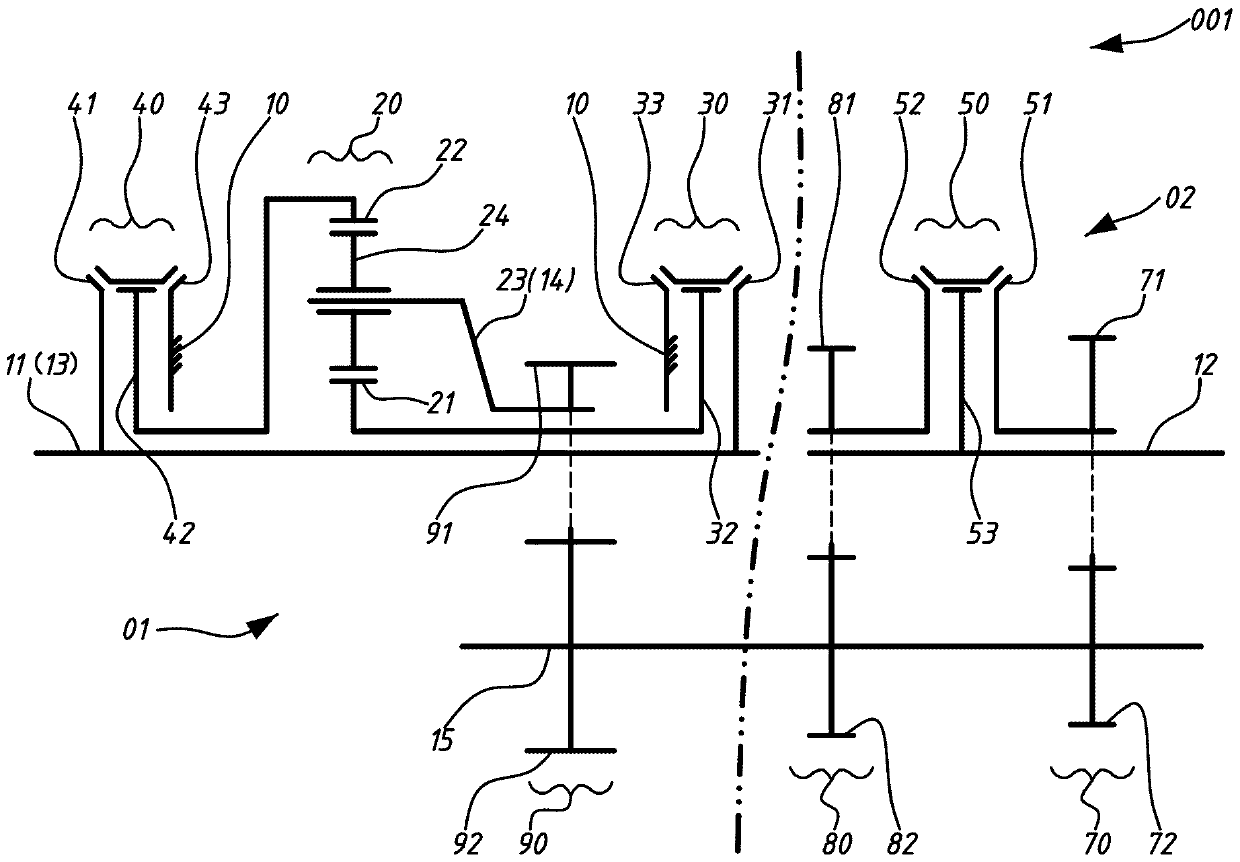

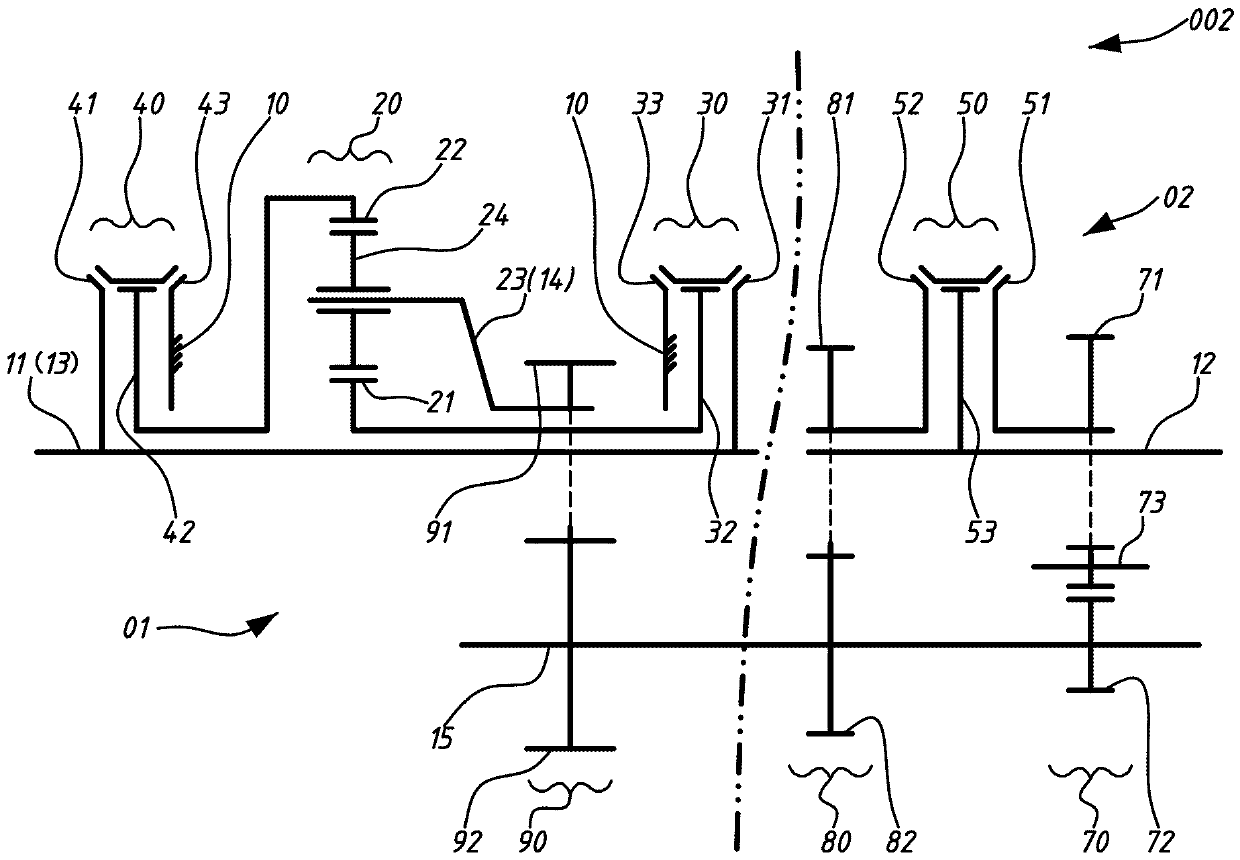

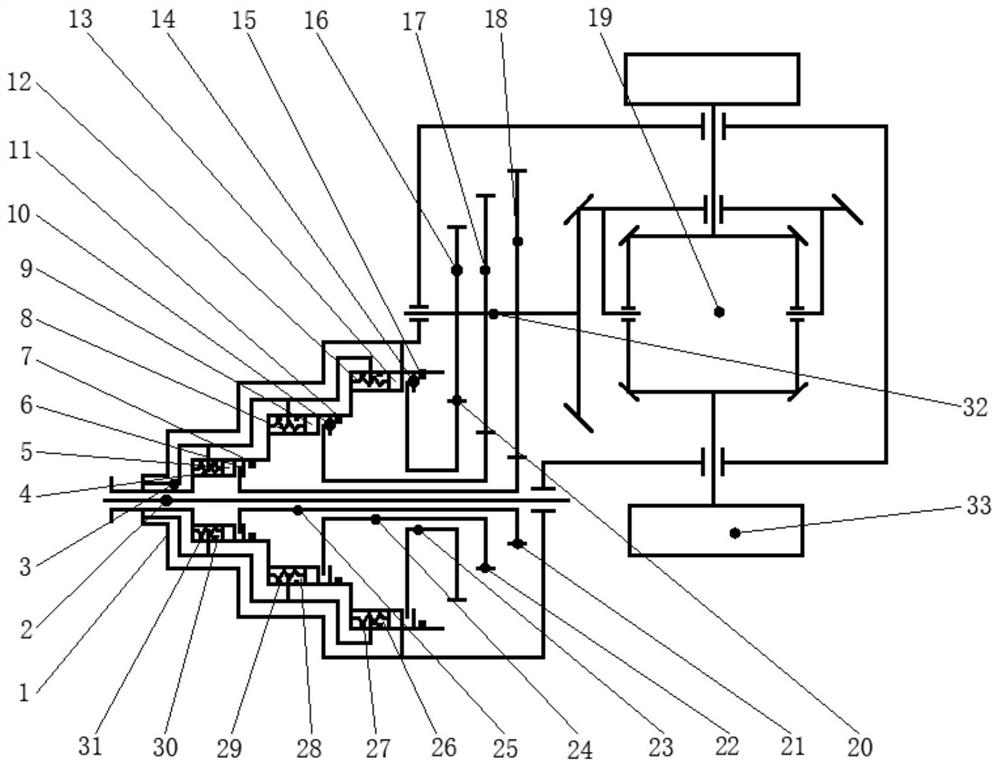

Eleven-gear transmission based on planetary gear train

ActiveCN112081884AExtended service lifeMany gearsToothed gearingsTransmission elementsClutchGear transmission

The invention relates to a transmission, and particularly relates to an eleven-gear transmission based on a planetary gear train. The eleven-gear transmission based on the planetary gear train solvesthe technical problem that an existing four-speed transmission and an existing six-speed transmission have limitations in the aspects of fuel economy, response power performance, stability and the like. The eleven-gear transmission based on the planetary gear train comprises a transmission shell and the planetary gear train. The planetary gear train comprises four planetary rows and seven gear shifting assemblies, wherein the four planetary rows and the seven gear shifting assemblies are arranged on the same shaft system; eight rotating bodies are formed among the four planetary row assembliesthrough connecting components such as rotating shafts; the gear shifting assemblies change the degree of freedom of the planetary gear train through clutches and brake; and different speed ratio transmission between an input shaft and an output shaft can be achieved through combination and separation of the different assemblies, and finally the gear shifting speed of at least eleven forward gearsand at least two reverse gears can be obtained. The eleven-gear transmission based on the planetary gear train has a more optimized speed ratio, and the power transmission performance and fuel economy of a vehicle are remarkably improved.

Owner:SHAANXI FAST GEAR CO

Three-wheeled automobile circulating type gear shifting conjoined rear axle

The invention discloses a three-wheeled automobile circulating type gear shifting conjoined rear axle which comprises a gearbox body. A power input shaft, a first power transmission shaft, a second power transmission shaft and a third power transmission shaft are installed in the gearbox body; a gear shifter is installed on the power input shaft and the first power transmission shaft in a slidingmode; a shifting fork shaft is installed in the gearbox body; a shifting fork for pushing the gear shifter to slide is installed on the shifting fork shaft in an axial sliding mode; and a circulatingtype speed changing control mechanism for driving the shifting fork is further installed in the gearbox body. Gear-up or gear-down can be completed only by pushing and pulling a gear lever forwards and backwards: the gear lever is pulled forward to add one gear and pushed backward to subtract one gear, and the gear-up and gear-down gear-shifting mechanism is similar to a manual-automatic integrated manual part. By means of the design, the gear shifting speed is increased, the possibility of wrong gear shifting is greatly reduced, and revolutionary upgrading of a three-wheeled automobile control mode is achieved. The rear axle further has the advantages of compact structure, reasonable design, convenience in user operation, effective reduction of gear shifting errors and the like.

Owner:WUZHENG

Double-clutch transmission

InactiveCN111520446AAchieve rotationFast gear shiftToothed gearingsGearing controlGear wheelControl theory

The invention belongs to the technical field of transmissions, and discloses a double-clutch transmission. The double-clutch transmission comprises a rack, wherein an input device, a shifting device and an output device are arranged on the rack; the input device comprises a first clutch, a second clutch, a first input shaft, a first input gear, a second input shaft and a second input gear; a plurality of shift gears are distributed on the periphery circumference of the first input gear, and a plurality of shift gears are also distributed on the periphery circumference of the second input gear;the output device comprises an output shaft and a plurality of shift gear sets connected with the output shaft, and the shift gears and the shift gear sets are arranged in one-to-one correspondence;and the shifting device is used for connecting a single shift gear with the input gear. When one clutch is hung in one gear, the other clutch and the corresponding downshift gear are already in a preparation state, and the next gear can be connected as long as the front gear is separated, so that the gear shifting speed is very high, and the smoothness is better.

Owner:雷兵

Lever-controlled clutch and speed change device

PendingCN111059168AAchieve power transmissionReduce friction lossFluid actuated clutchesGearing controlPlate pressureGear wheel

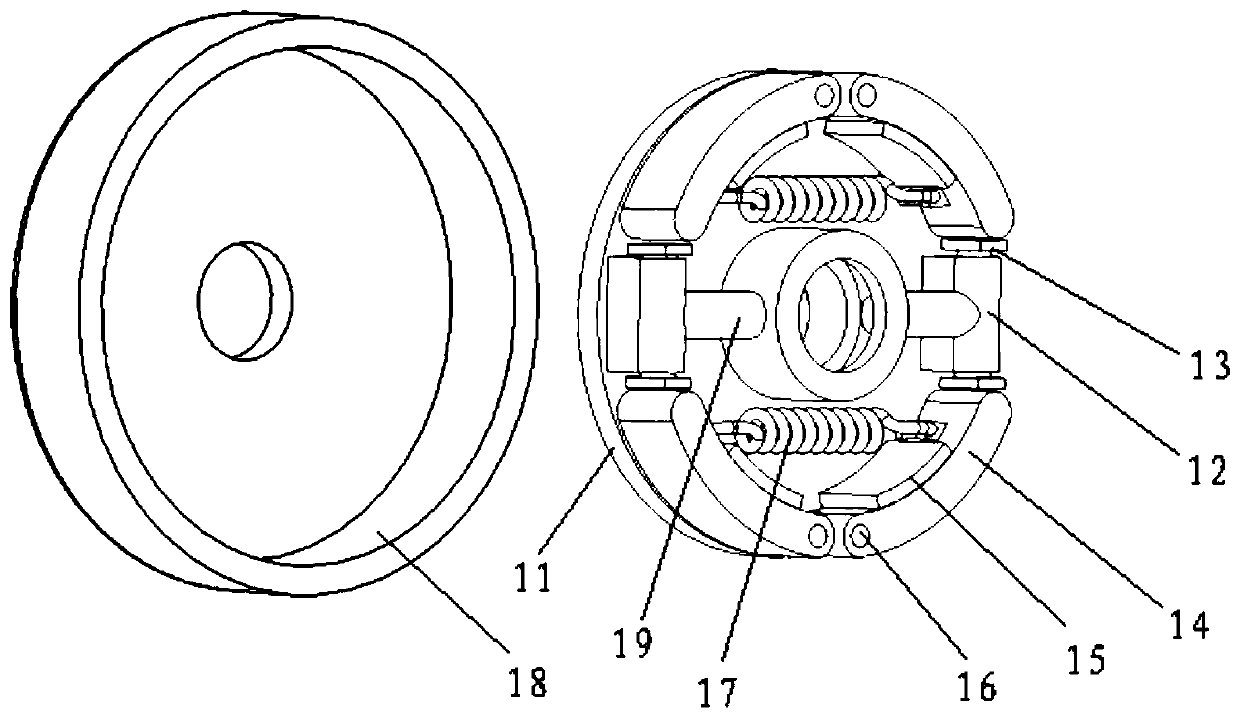

The invention provides a lever-controlled clutch and a speed change device. The clutch is arranged on a shaft body; the clutch comprises a gear, a clutch shell, a spline body, a friction plate pressure plate, a pressure plate bearing and a pressure plate which sequentially sleeve the shaft body; the gear is fixed with the clutch shell; the spline body is fixed with the shaft body; a first frictionplate and a second friction plate sleeve the spline body; the outer circumference of the first friction plate is clamped with the clutch shell; the inner circumference of the second friction plate isclamped with the spline body; a return spring is arranged in the axial direction of the spline body; the return spring is used for returning of the friction plate pressure plate; one side of the pressure plate is provided with a lever mechanism; the lever mechanism comprises a clutch push rod and a support column; the clutch push rod is in pivot joint with the support column; and one end of the clutch push rod is pressed against the pressure plate. The clutch provided by the invention can realize large-torque transmission between the shaft body and the gear, and transmission efficiency is improved at the same time.

Owner:尚尔航

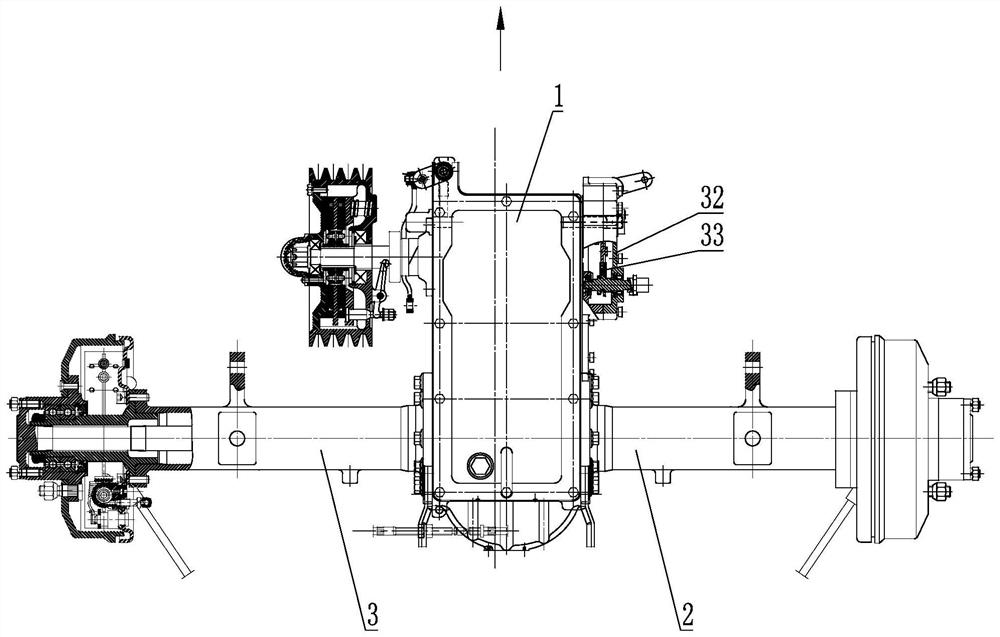

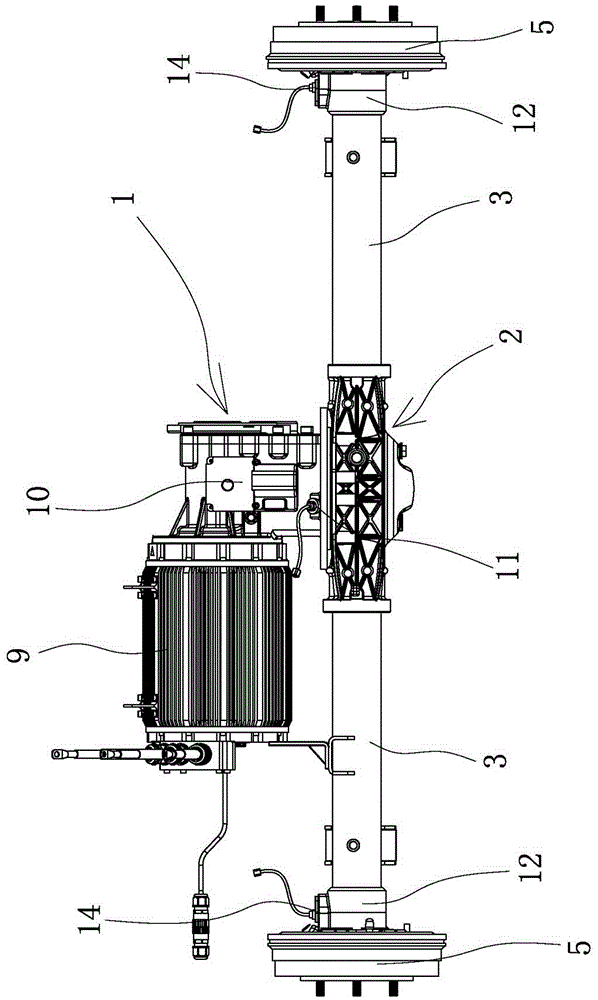

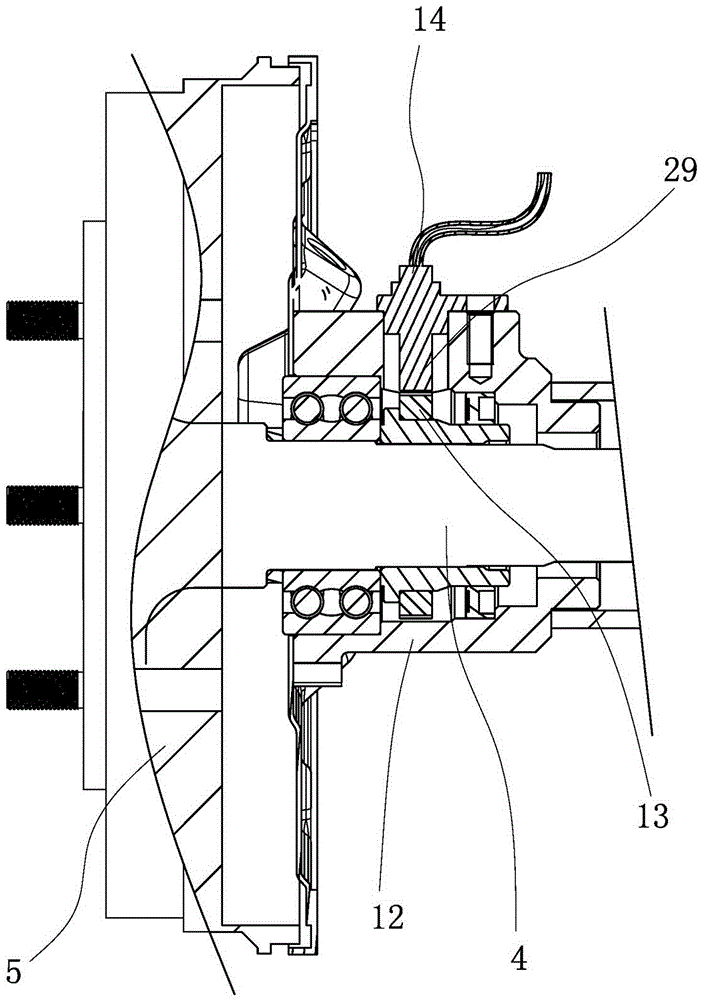

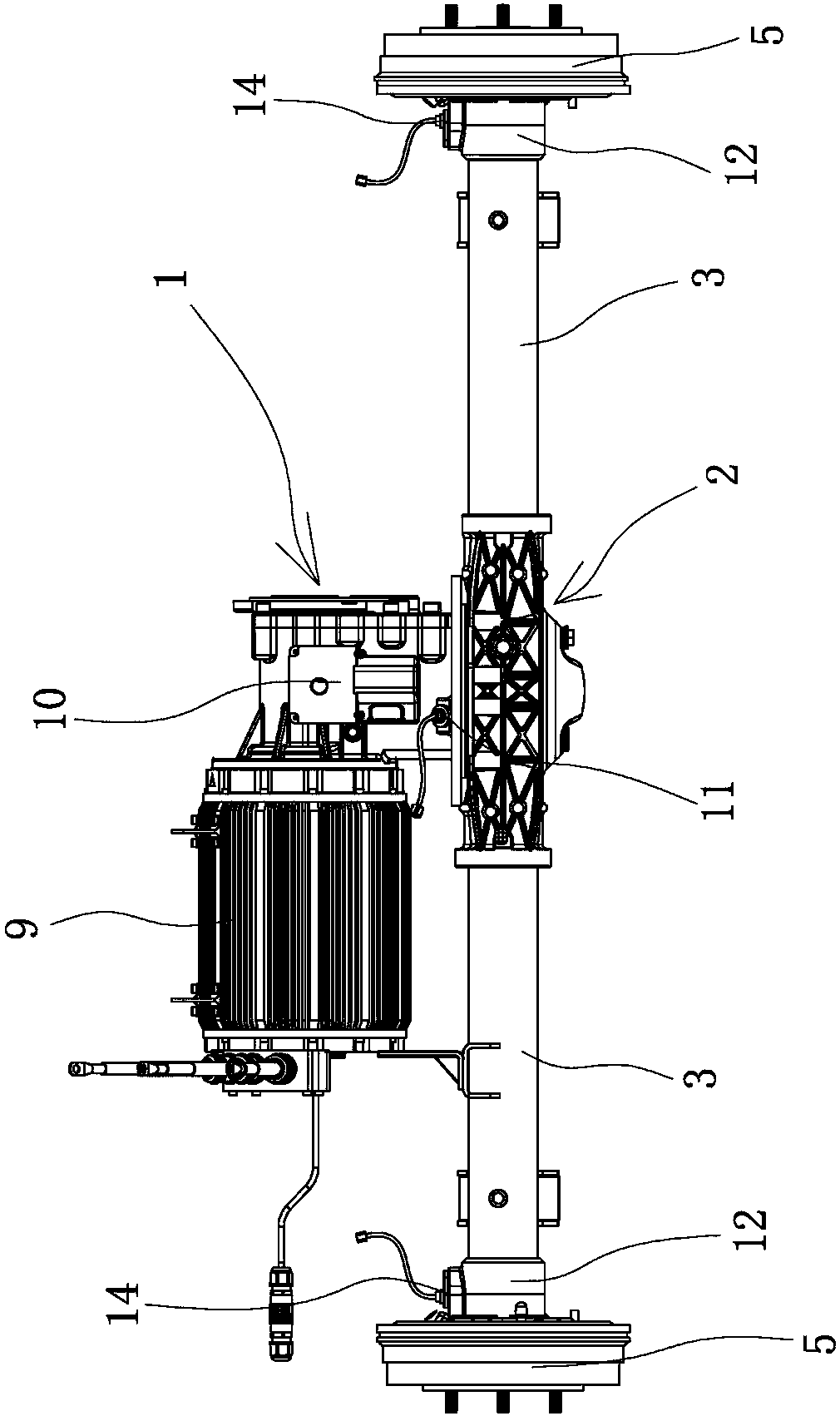

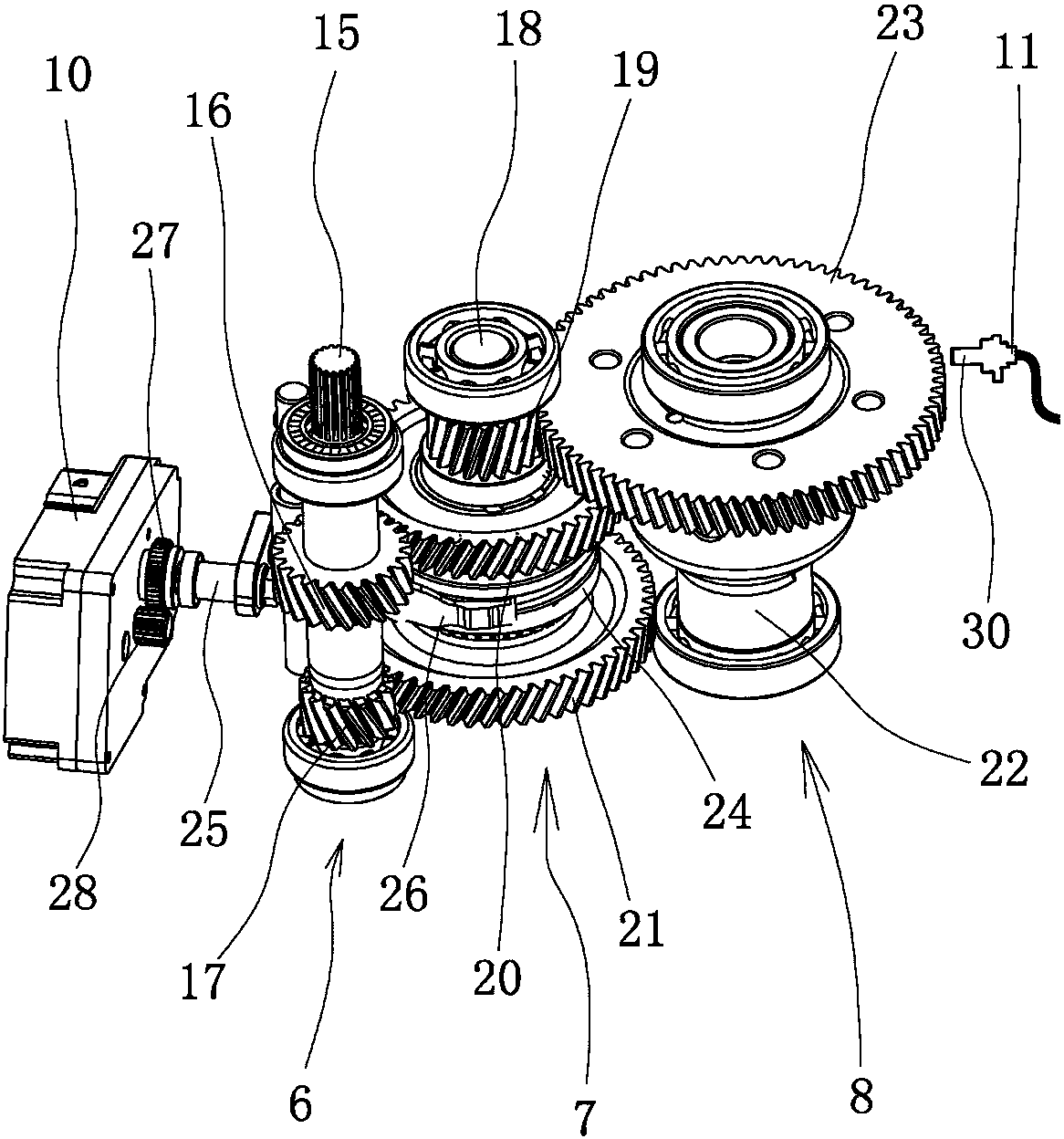

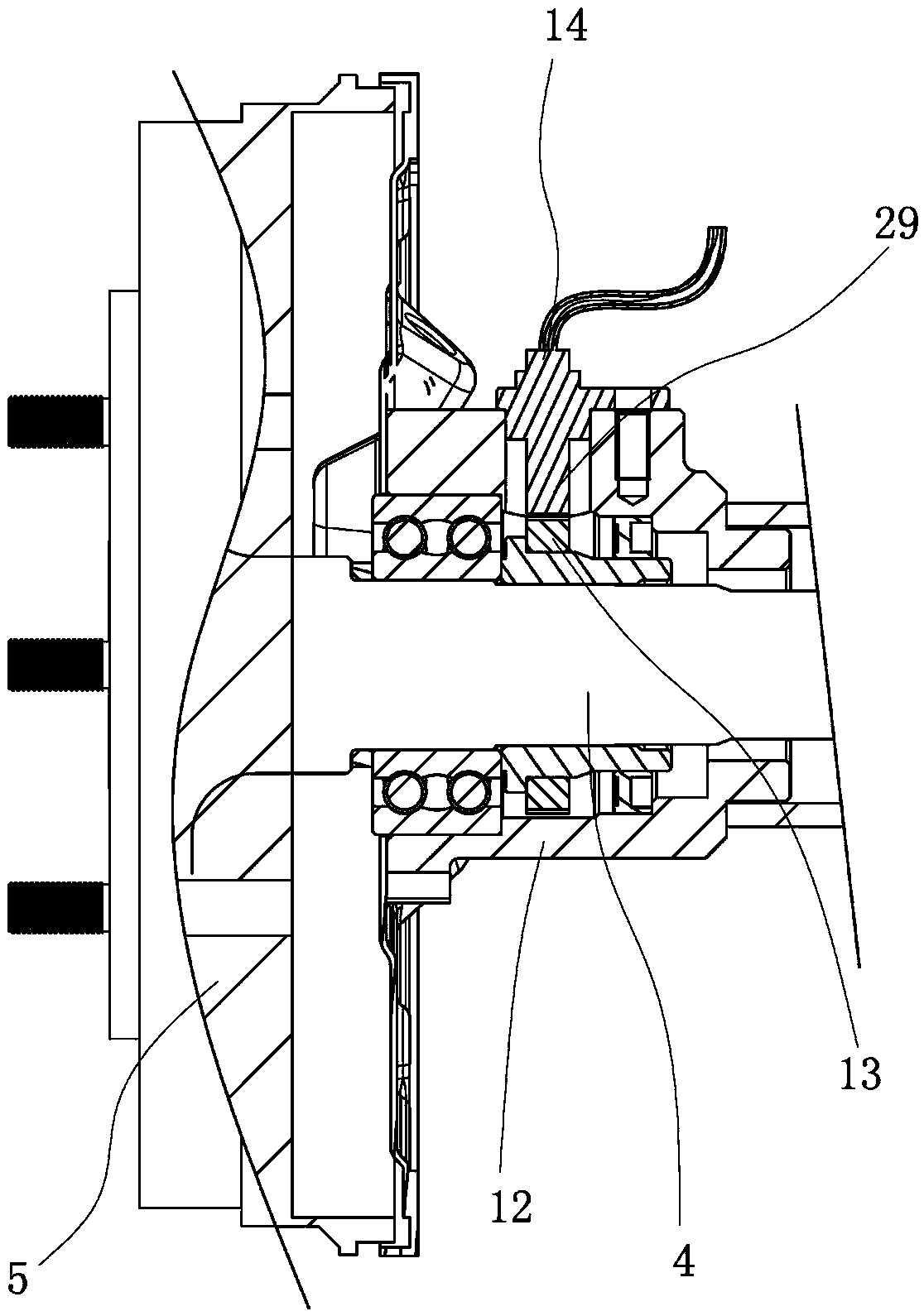

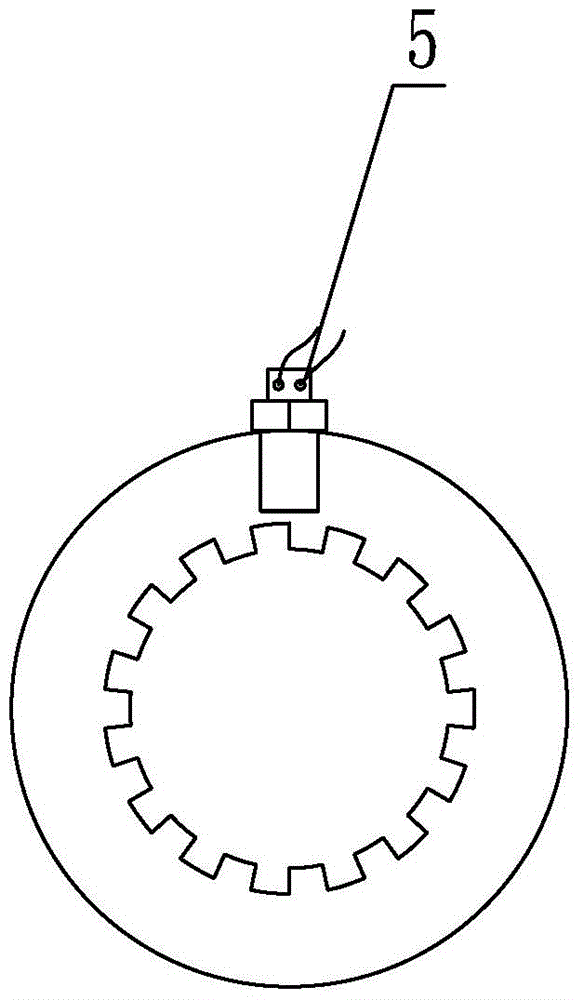

Electric automobile rear axle assembly with an ABS automatic shifting function

PendingCN106585348AFast gear shiftAccurate gear shiftElectric propulsion mountingGearing controlMotor driveElectric machine

The invention provides an electric automobile rear axle assembly with an ABS automatic shifting function, and belongs to the technical field of electric automobiles. According to the electric automobile rear axle assembly, the problems that energy consumption of an existing electric automobile rear axle is high and shifting cannot be conducted automatically are solved. The electric automobile rear axle comprises a decelerator, a differential mechanism and two bridge tubes connected on the differential mechanism. Half shafts penetrate through the bridge tubes, and braking drum plates driven to rotate by the half shafts are arranged at the outer ends of the bridge tubes. The decelerator is composed of an input gear assembly, a shifting gear assembly and an output gear assembly; a shell of the decelerator is connected to a main motor driving the input gear assembly to work, and a shifting motor capable of driving the shifting gear assembly to shift; and the shell of the decelerator is further provided with a speed sensor capable of monitoring the speed of the output gear assembly, signals monitored by the speed sensor are transmitted to a trip computer, and the trip computer sends shifting commands to the shifting motor after analyzing the signals. The electric automobile rear axle assembly with the ABS automatic shifting function has the advantages of high degree of automation, low energy consumption and accurate shifting.

Owner:TAIZHOU HENGYUE IND & TRADE CO LTD

Rear axle assembly of electric automobile

InactiveCN109795299AFast gear shiftAccurate gear shiftElectric propulsion mountingToothed gearingsReduction driveElectric machine

The invention provides a rear axle assembly of an electric automobile, and belongs to the technical field of electric automobiles. The assembly solves the problems that the rear axle of the existing electric automobile has high energy consumption and cannot automatically shift gears. The rear axle of the electric automobile comprises a speed reducer, a differential and two bridge tubes connected to the differential, wherein half shafts are arranged in the bridge tubes in a penetrating manner; brake drum discs driven to rotate by the half shafts are arranged at the outer end parts of the bridgetubes; the speed reducer consists of an input gear assembly, a shift gear assembly and an output gear assembly; a main motor capable of driving the input gear assembly to work is connected to an outer shell of the speed reducer; a shift motor capable of driving the shift gear assembly to shift gears is arranged on the outer shell of the speed reducer; a speed sensor capable of monitoring the output gear assembly is arranged on the outer shell of the speed reducer; a signal monitored by the speed sensor is transmitted to a traveling computer; and the traveling computer analyzes the signal andsends a shift instruction to the shift motor. The assembly has the advantages of high automation degree, low energy consumption and accurate gear shifting.

Owner:TAIZHOU HENGYUE IND & TRADE CO LTD

Central overrunning clutching synchronizer gearbox for electric bicycle

PendingCN110406623AGuaranteed reliabilityFast gear shiftWheel based transmissionAutomotive engineeringElectric bicycle

The invention discloses a central overrunning clutching synchronizer gearbox for an electric bicycle. The gearbox comprises a dead axle and a moving axle, wherein the dead axle and the moving axle areindependently provided with multiple levels of gears; the gears on the dead axle and the gears on the moving axle are subjected to constant meshing arrangement one by one; the gears on the moving axle can be rotatably sheathed to the moving axle relative to the moving axle; a spline which carries out axial movement along the moving axle and synchronously operates with the moving axle is installedin the moving axle; the spindle is pulled and driven by a steel wire to move; the gears on the moving axle are independently provided with a spline groove which synchronously operates after the gearsare cooperated with the spline. Each gear on the moving axle corresponds to a tap position, the tap position is changed through the movement of the spline, tap position can be realized through pulling a steel wire even if parking is carried out, and tap position change speed is high. Meanwhile, a constant meshing way is adopted to enable the structure of the gearbox to be compact, small in spaceand convenient in use.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

An eleven-speed transmission based on a planetary gear train

ActiveCN112081884BImprove power transmission performanceImprove fuel economyToothed gearingsTransmission elementsRotational axisGear wheel

The present invention relates to a transmission, in particular to an eleven-speed transmission based on a planetary gear train, which solves the limitations of existing four-speed and six-speed transmissions in terms of fuel economy, responsiveness, and stability. question. The eleven-speed transmission based on the planetary gear system of the present invention includes a transmission housing and a planetary gear system. The planetary gear system includes four planetary rows and seven shifting assemblies arranged on the same shaft system. The four planetary row assemblies pass through The rotating shaft and other connecting components form eight rotating bodies. The shifting component uses clutches and brakes to change the degree of freedom of the planetary gear train. The shifting speed of at least eleven forward gears and at least two reverse gears is obtained, with a more optimized speed ratio, which significantly improves the power transmission performance and fuel economy of the vehicle.

Owner:SHAANXI FAST GEAR CO

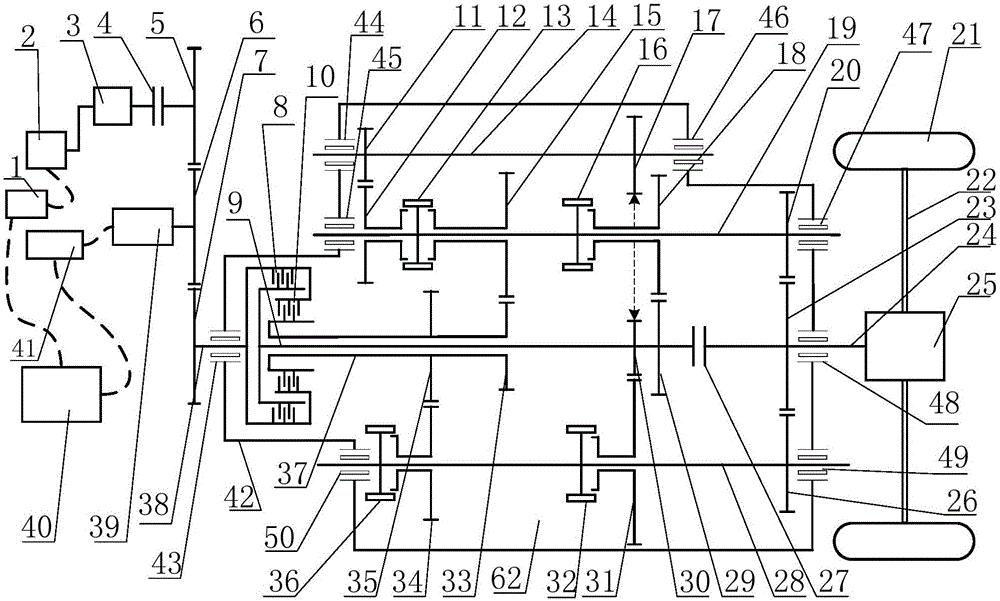

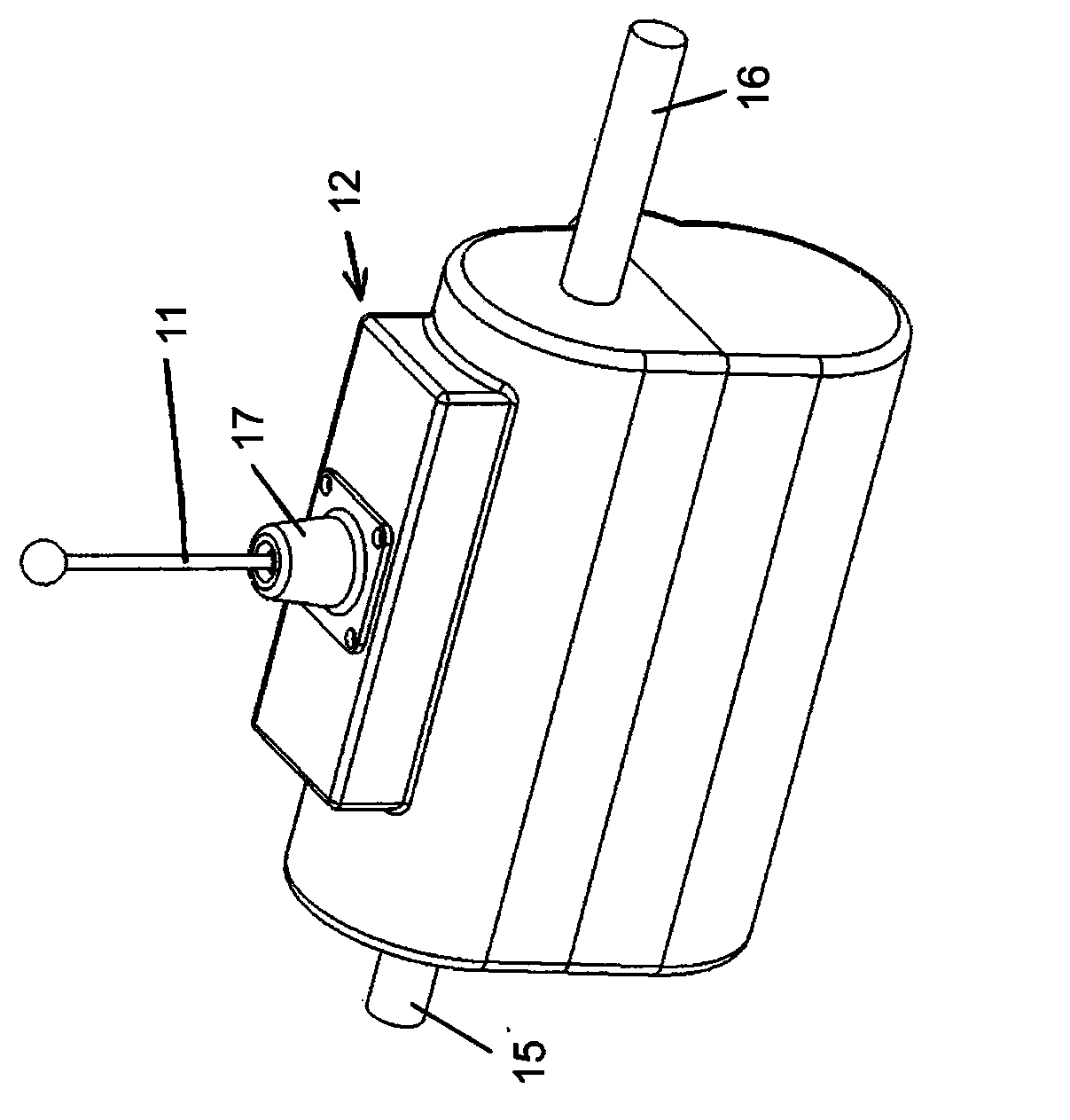

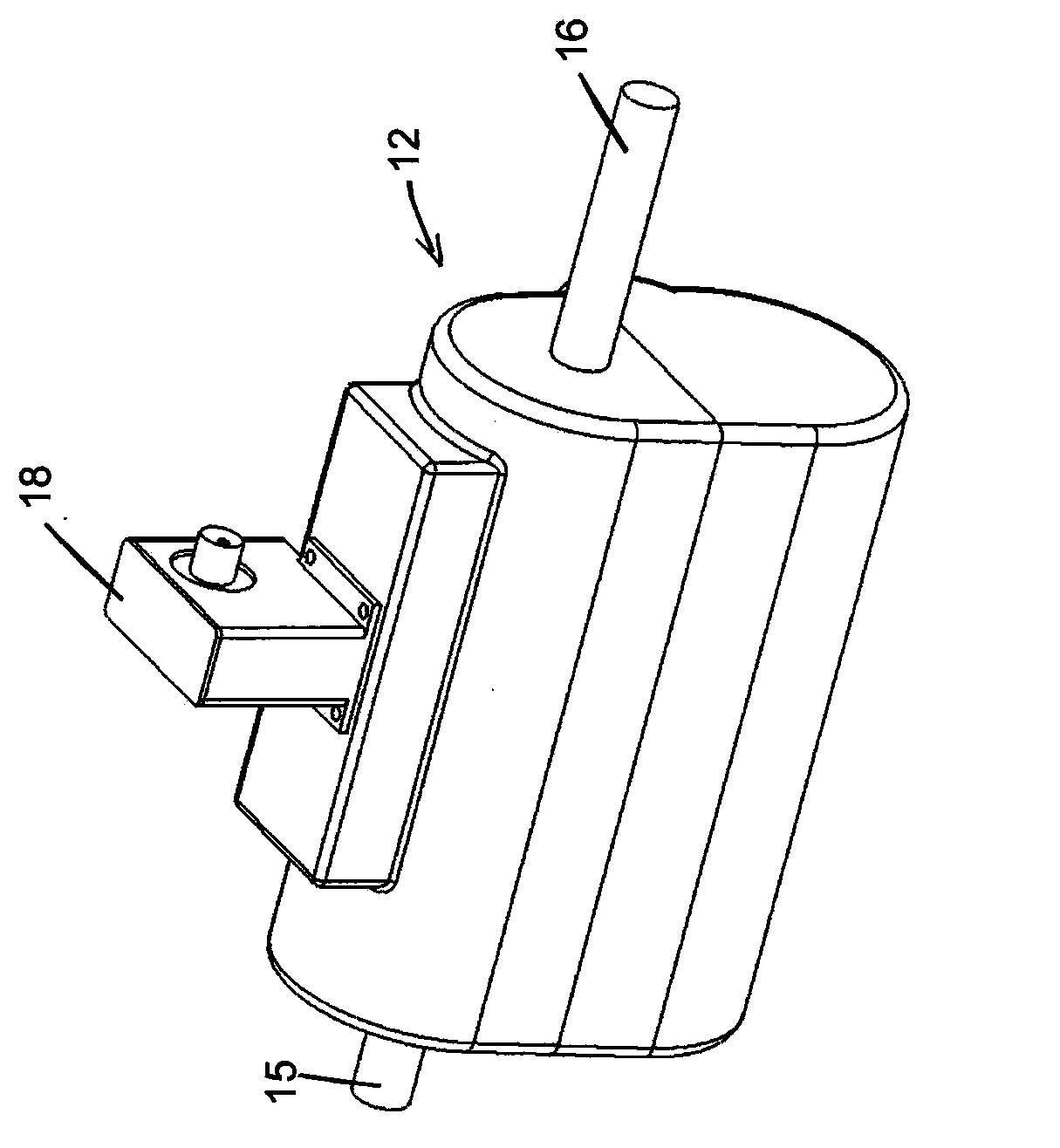

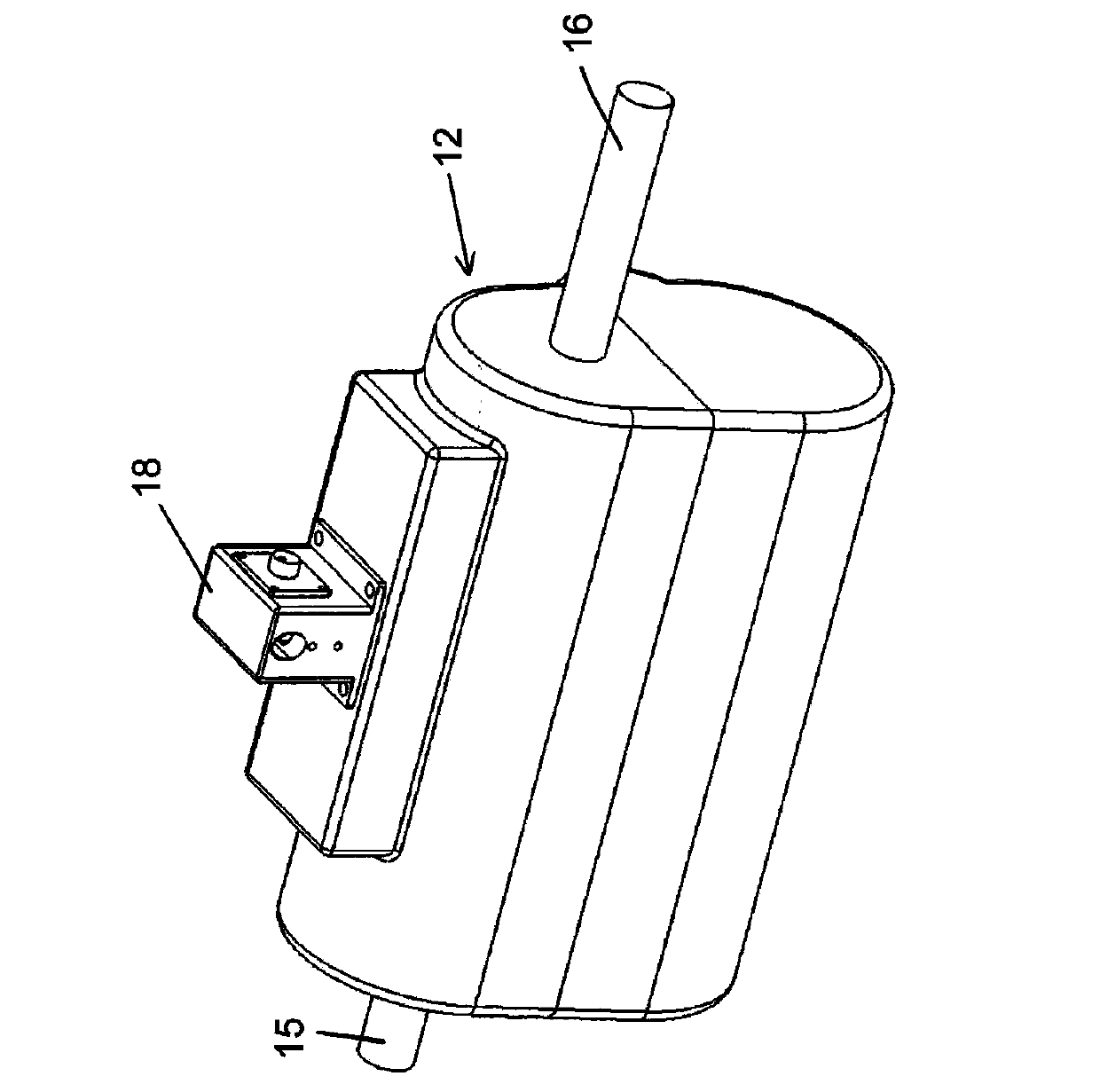

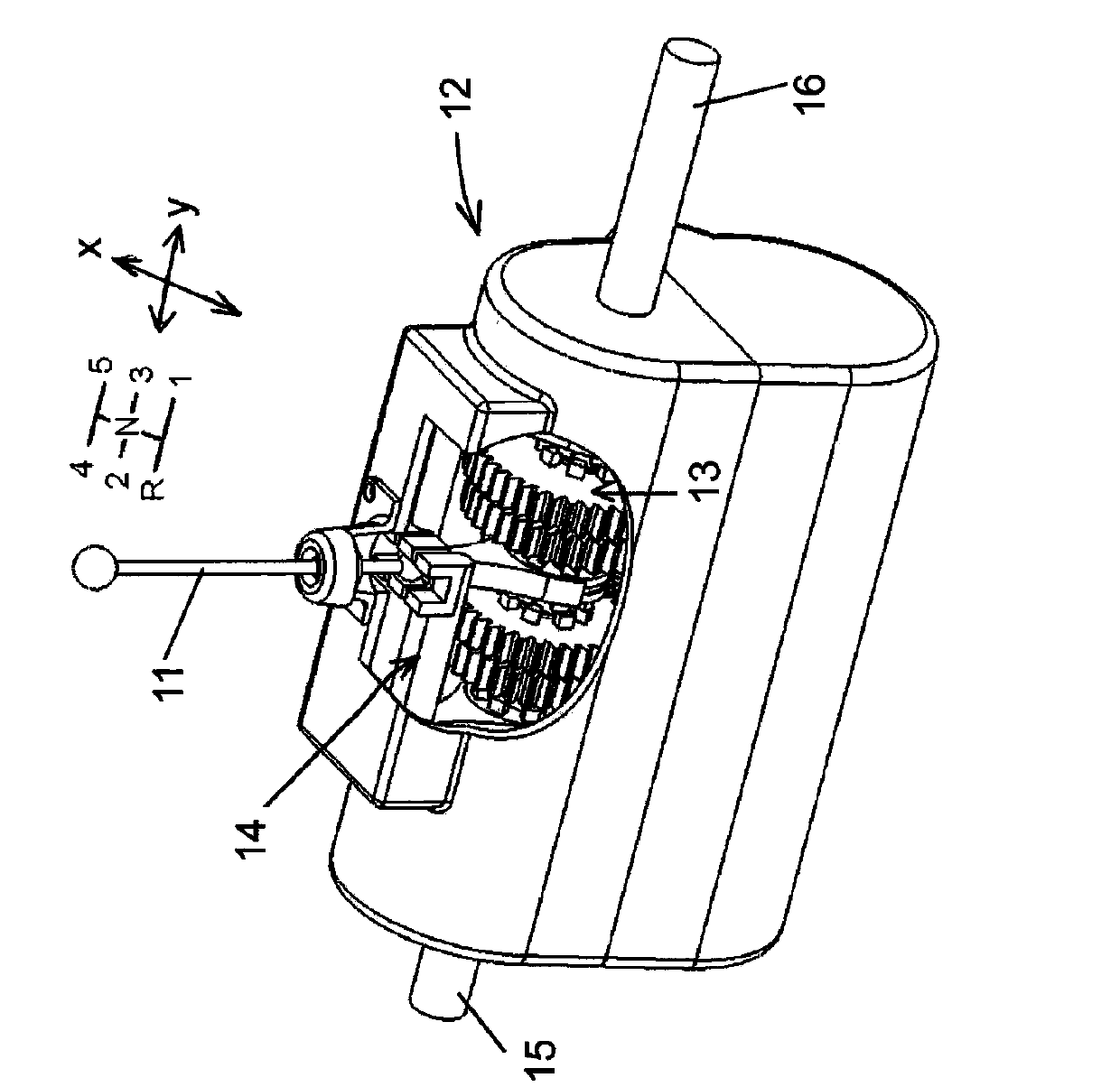

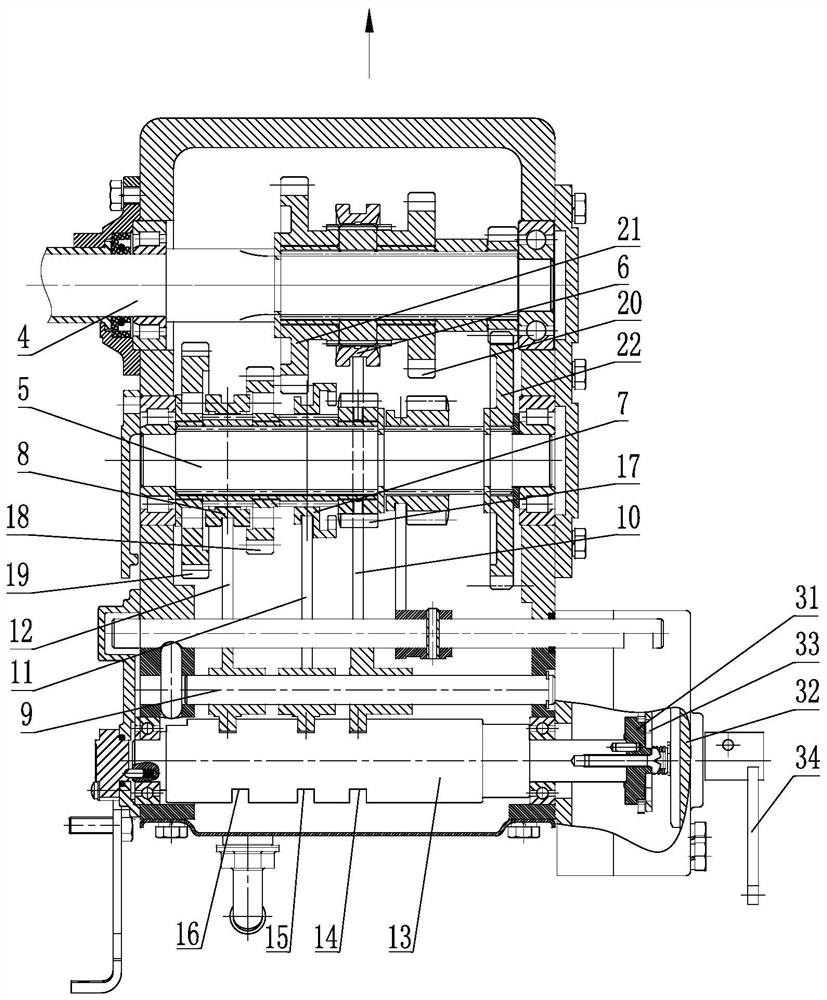

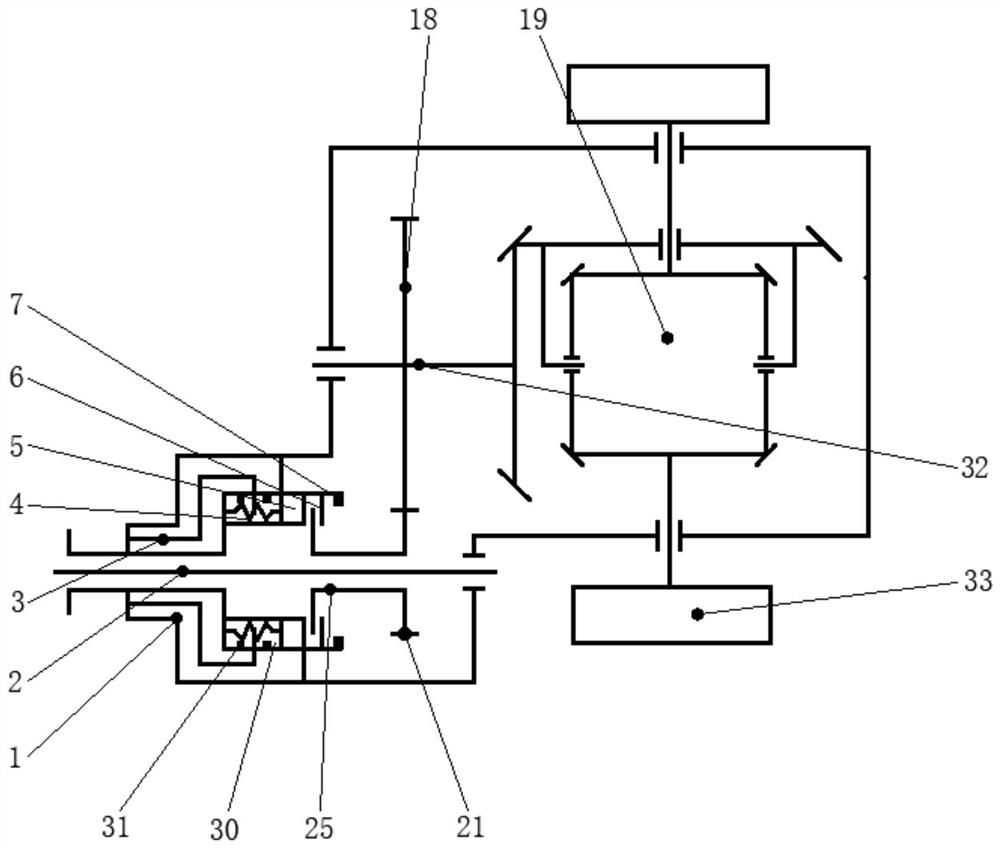

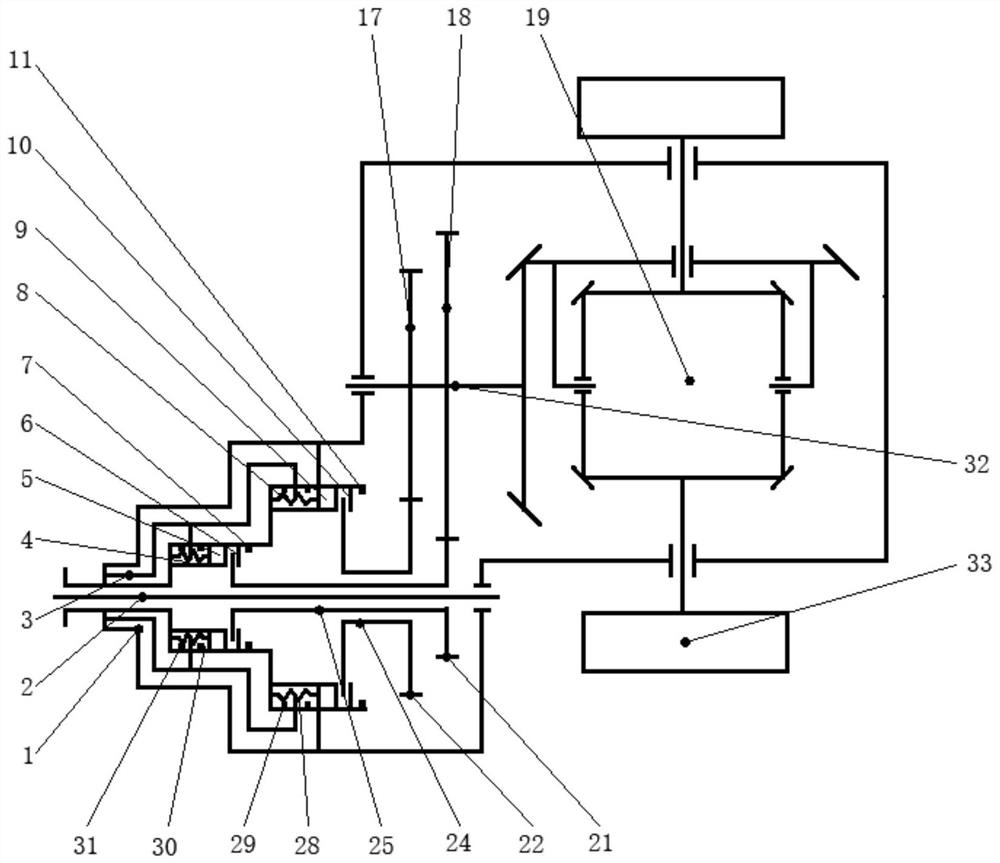

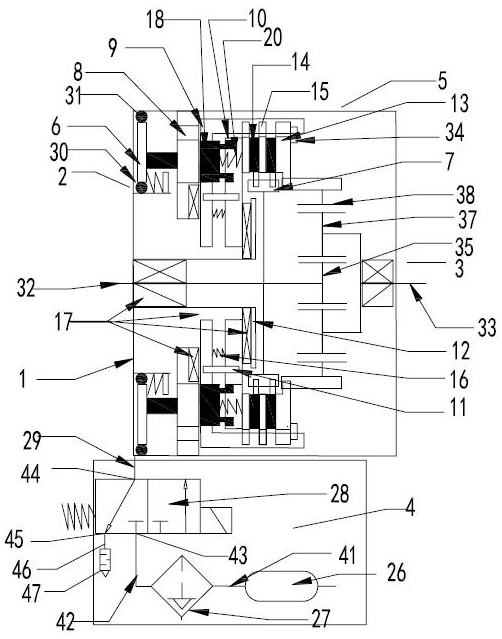

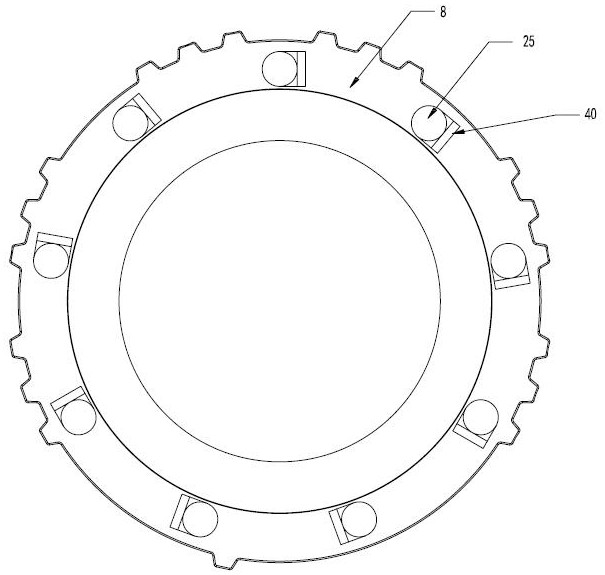

A stepped n-speed wet clutch structure

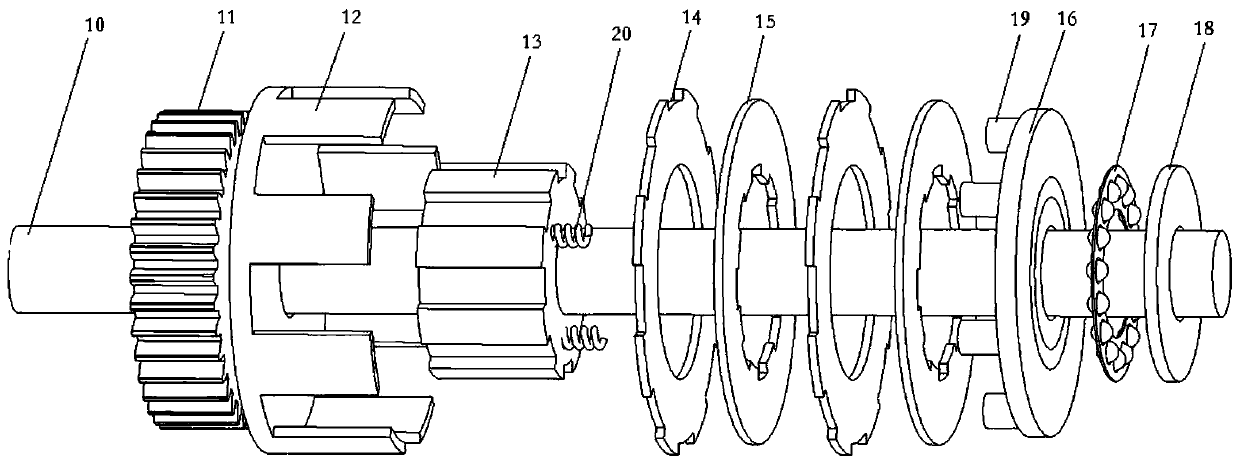

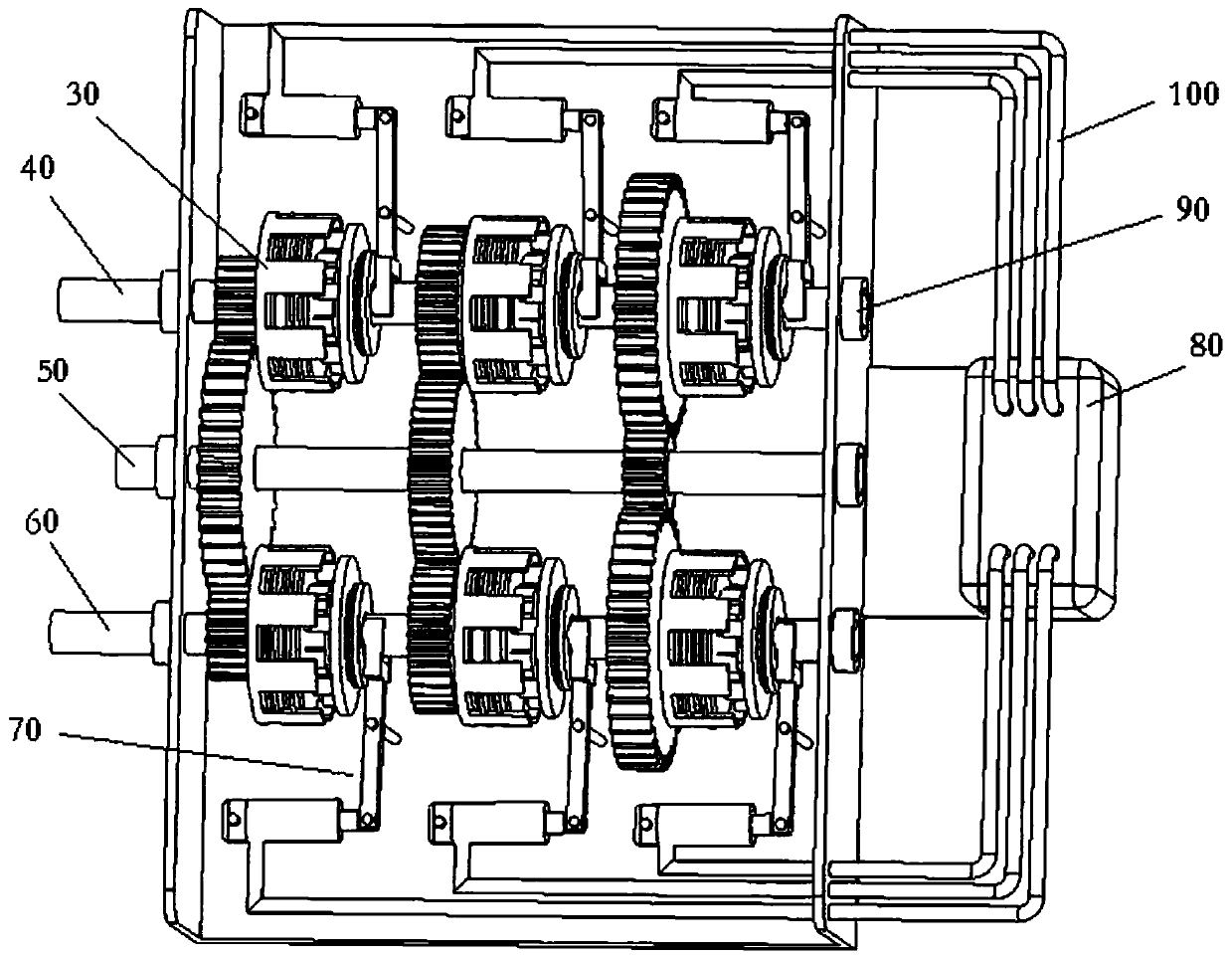

ActiveCN111810552BImprove carrying capacityImprove cooling effectFluid actuated clutchesToothed gearingsGear driveGear wheel

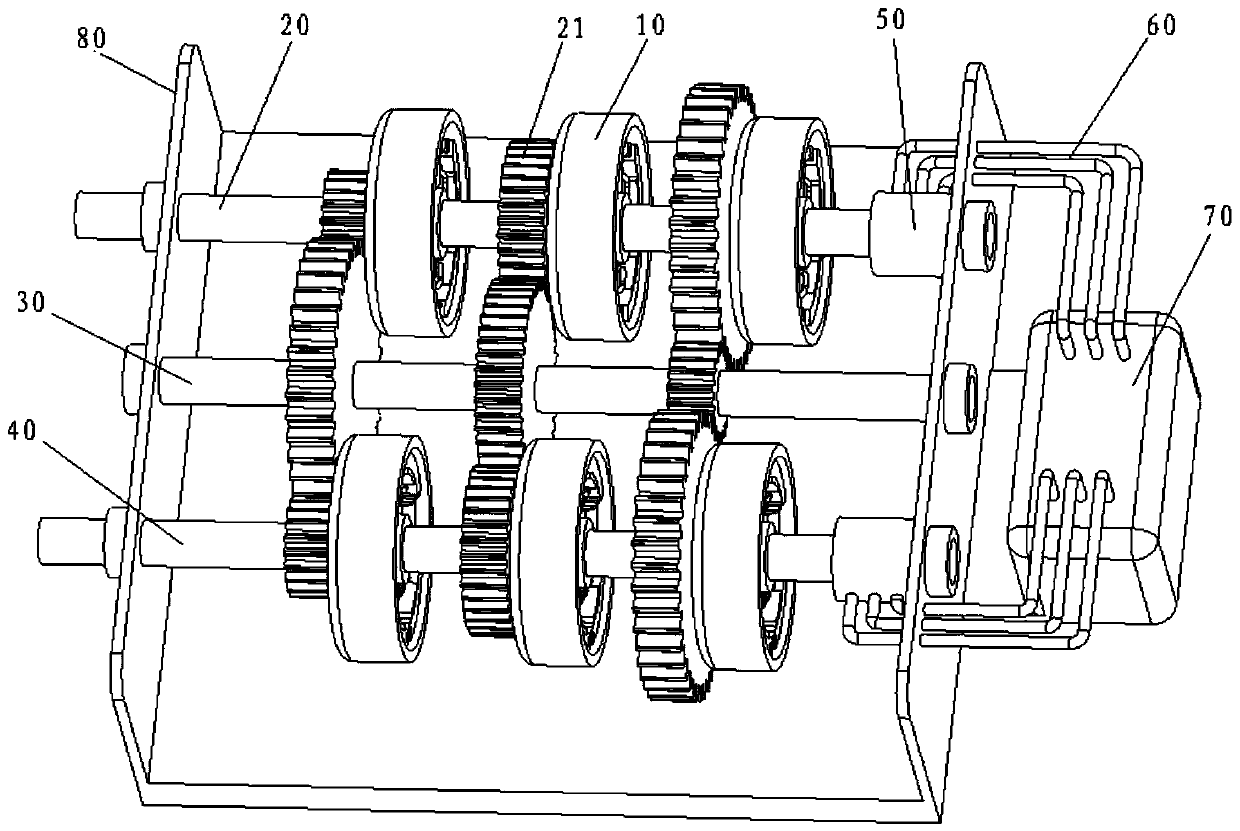

The invention discloses a stepped n-gear wet clutch structure, which is characterized by comprising a casing, an oil delivery pipe, a piston, a sealing ring, a stop washer, a return spring, a clutch plate, a gear shaft, a gear ring gear and a gear transmission structure, The movement of the piston is controlled by the hydraulic pressure, the return spring accelerates the return speed of the piston, the sealing ring prevents the leakage of hydraulic oil, the stop washer fixes the position of the clutch plate, the gear shafts are all hollow shafts, and are nested layer by layer. Circle solid connection. The structure of the invention has large bearing capacity, good heat dissipation performance and wide application range; the stepped shell design shape saves space and is compact in structure; adopts the concept of modularization, can be extended continuously and has wide application prospects.

Owner:HEFEI UNIV OF TECH

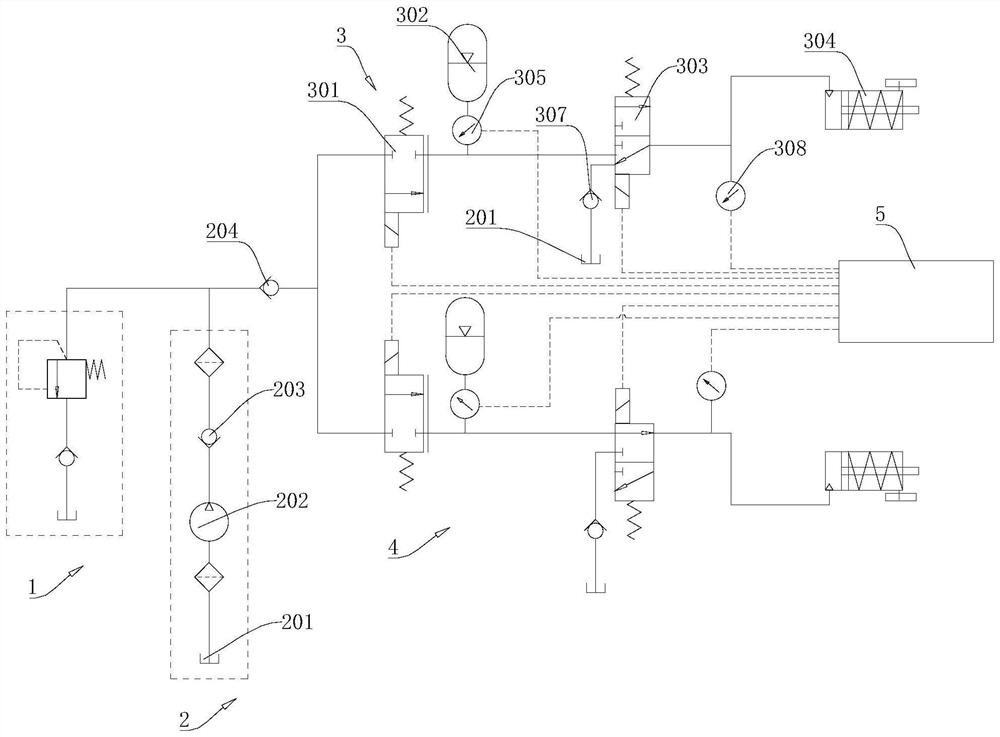

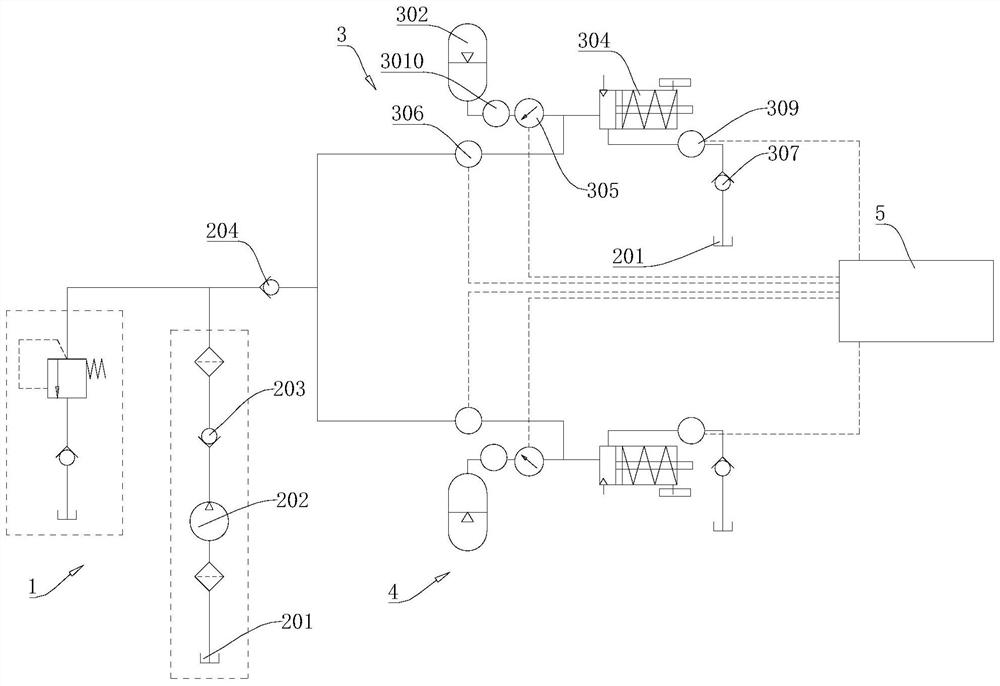

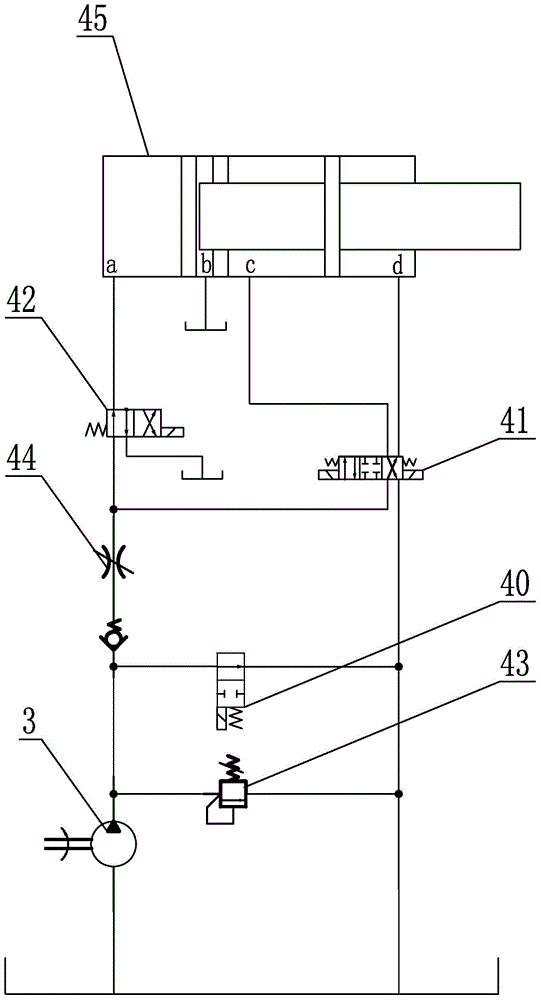

Hydraulic gear shifting system of dual-clutch transmission

PendingCN114688246AAvoid running continuouslyReduce energy consumptionGearing controlFluid-pressure actuator componentsHydraulic cylinderClutch

The invention provides a double-clutch transmission hydraulic gear shifting system which comprises an oil supply device, a first oil way, a second oil way and a controller. The first oil way and the second oil way are connected to the oil outlet end of the oil supply device in parallel. Each of the first oil way and the second oil way comprises an energy accumulator and a hydraulic cylinder which are connected with the oil outlet end of the oil supply device, and further comprises a first detector connected with the energy accumulator, the first detector is in communication connection with the controller, and the oil outlet end of the hydraulic cylinder is connected with the oil inlet end of the oil supply device. According to the hydraulic gear shifting system of the double-clutch transmission, energy consumption generated in the gear maintaining and gear shifting process of an oil supply device of the double-clutch transmission is reduced.

Owner:HEBEI UNIV OF TECH

Mechanical automatic shift control

The invention relates to a mechanical and automatic gear shifting control device. The mechanical and automatic gear shifting control device comprises a gear shifter, a controller, at least one gear shifting execution mechanism and a hydraulic pump, wherein the controller is connected with the gear shifter and is used for comparing rotating speed signals of an input shaft and an output shaft and sending a gear shifting instruction; the gear shifting execution mechanism is used for executing gear shifting; the hydraulic pump is connected to an oil tank and is used for providing hydraulic oil for the gear shifting execution mechanism; the gear shifting execution mechanism, the hydraulic pump and the controller are connected with one another. A clutch is not needed, the optimum gear shifting time is automatically calculated, the gear shifting speed is high, and the manufacturing cost is low.

Owner:SUZHOU DAFANG SPECIAL VEHICLE

Hybrid drive system with three-clutch automatic transmission and control method

InactiveCN104999902BAdapt to the requirements of different power demandsGive full play to the total powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingAutomatic transmissionElectric machine

The invention discloses a hybrid drive system with a three-clutch automatic transmission and a control method. In order to overcome the problems in the existing hybrid drive system that the total power of the engine and the drive motor cannot be fully utilized or the drive motor cannot always operate at its optimum Problems within the speed range of output characteristics, a hybrid drive system with a three-clutch automatic transmission includes a first power converter, a starter / generator integrated machine, an engine, a fourth clutch, a drive motor, an energy storage device, a second power converter, The three-clutch automatic transmission, the differential, the fourth clutch output shaft gear, the drive motor output shaft gear and the transmission input shaft gear; the transmission input shaft gear is installed on the transmission input shaft in the three-clutch automatic transmission, the fourth The clutch output shaft end gear, the drive motor output shaft end gear and the transmission input shaft end gear are meshed and connected sequentially. The invention also provides a control method of the three-clutch automatic transmission.

Owner:JILIN UNIV

Fast slewing pseudorandom noise sequence generator and executing method thereof

InactiveCN1210648CFast gear shiftRandom number generatorsMultiplex code generationOffset distanceCommand and control

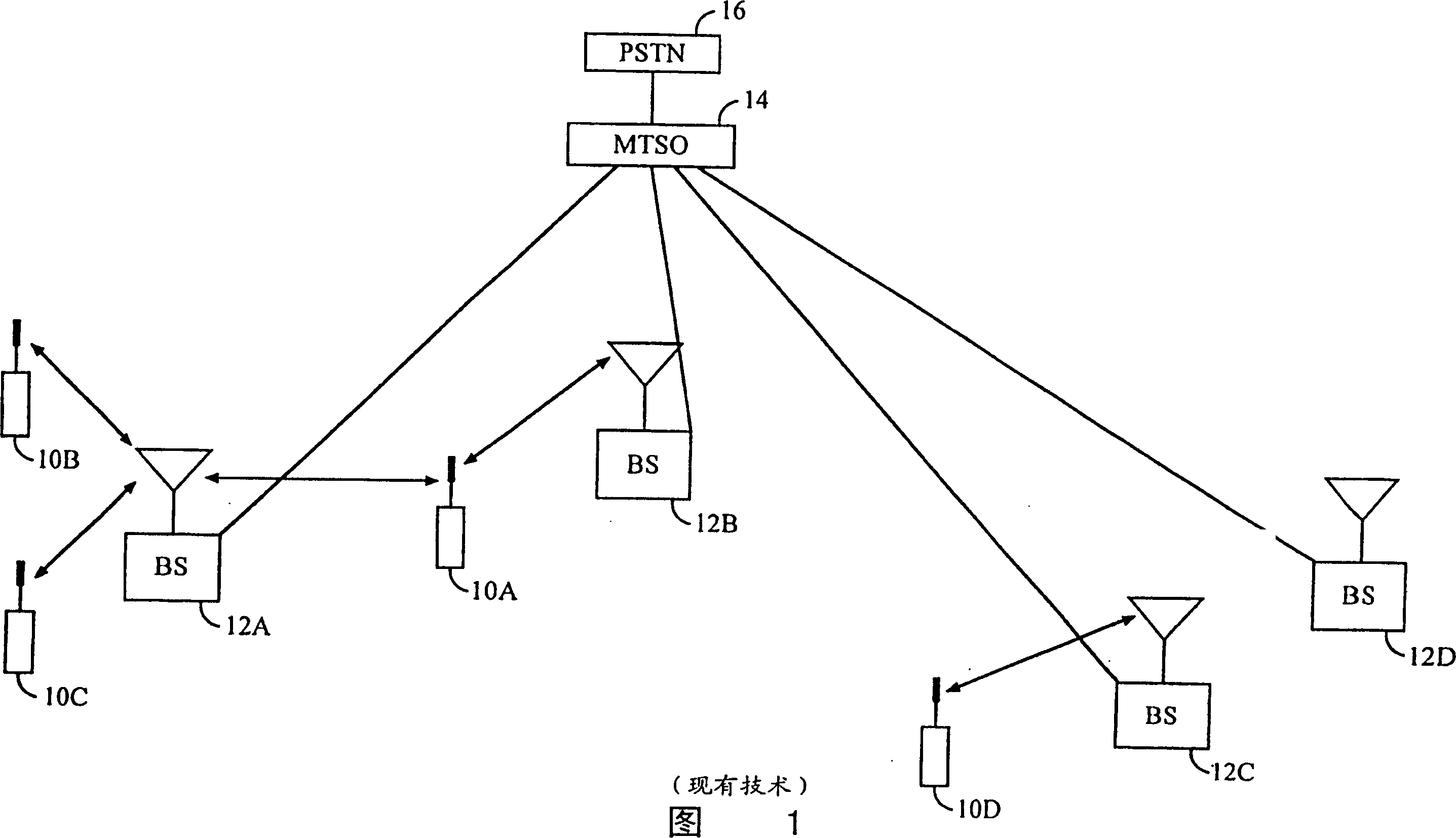

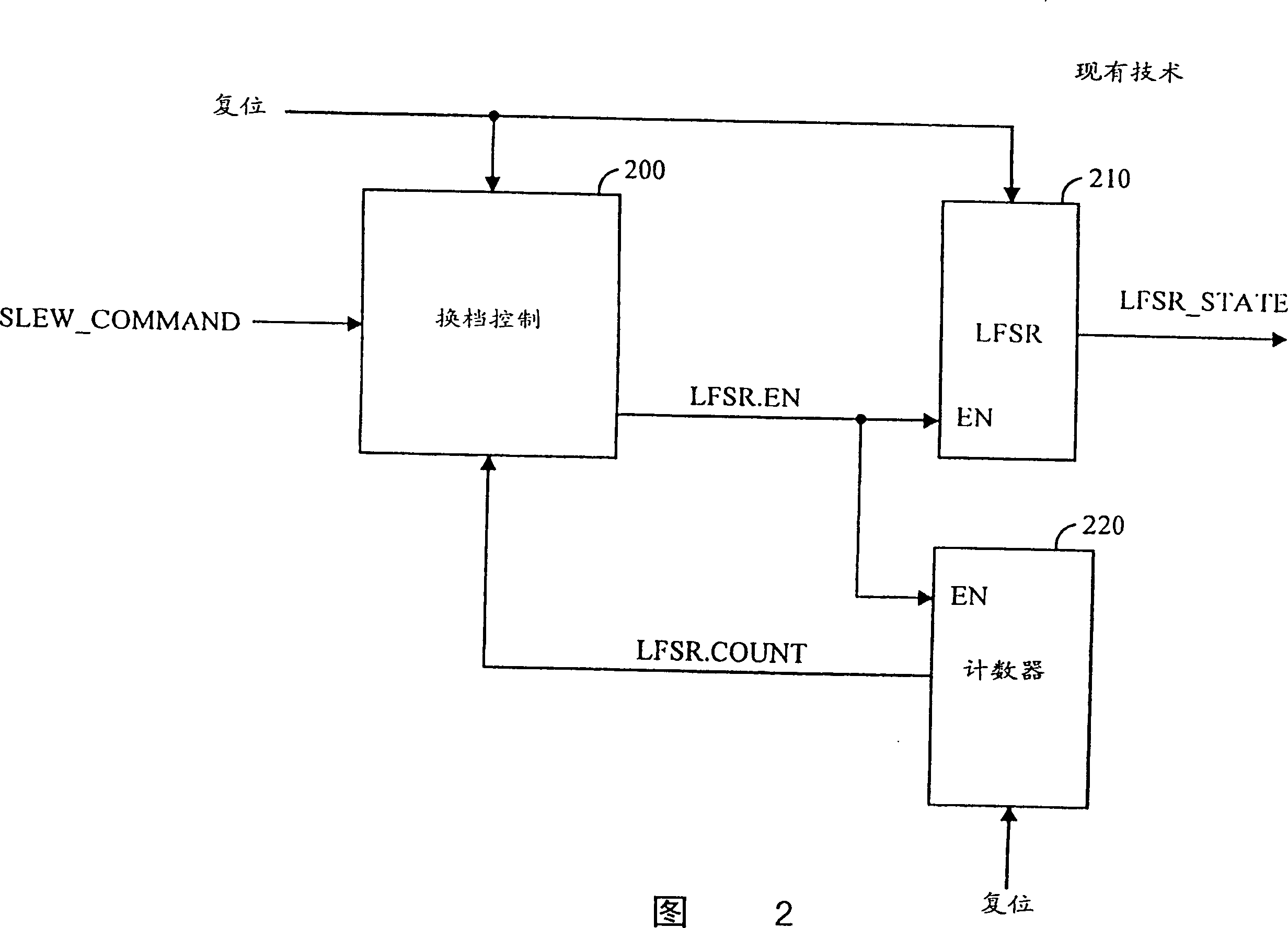

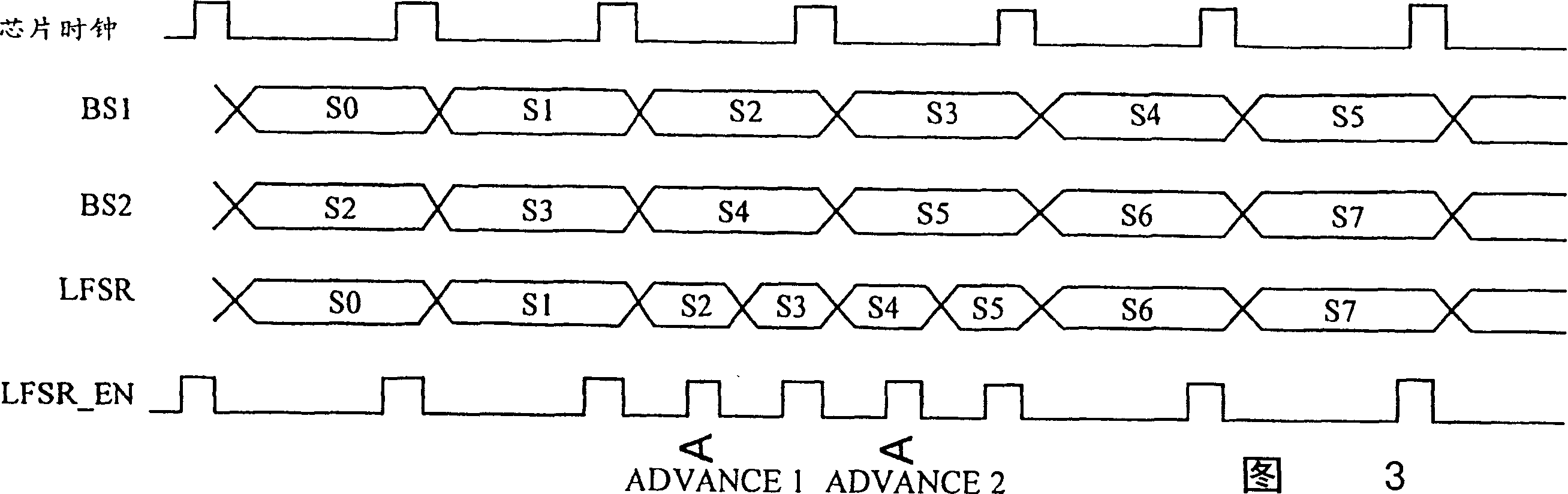

A novel and improved method and apparatus for a fast-slewing pseudorandom noise sequence generator is described. One or more loadable PN generators are controlled by a DSP or microprocessor in conjunction with a free-running counter which maintains a reference offset count. The PN generator will typically be part of a finger or searcher. The DSP or microprocessor may assist in other finger or searcher functions as well as the slew function, and can control one or more fingers and / or searchers. Each PN generator is comprised of a loadable linear feedback shift register (LFSR) or its equivalent, a loadable counter for maintaining an index of the state of that particular PN generator, and a slew control device capable of receiving a slew command and controlling the LFSR and index counter to enact an advance or a retard of a certain offset distance.

Owner:QUALCOMM INC

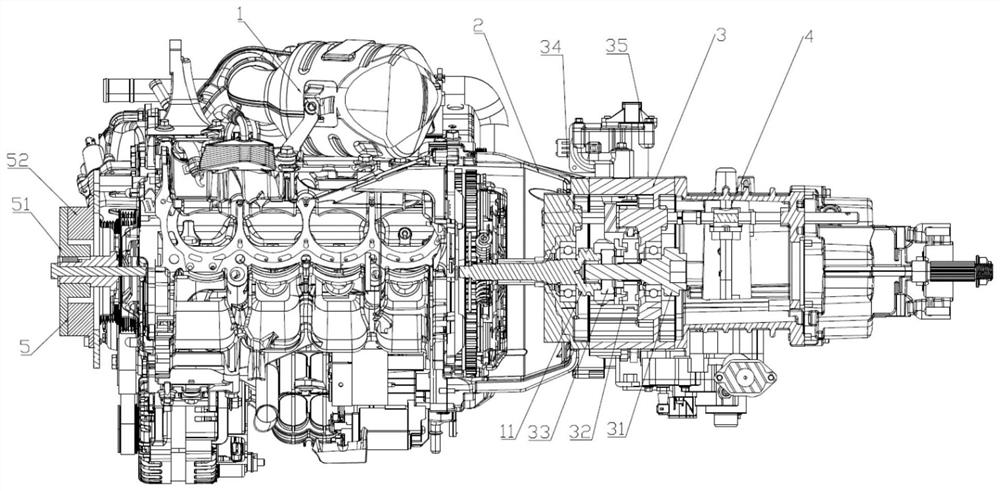

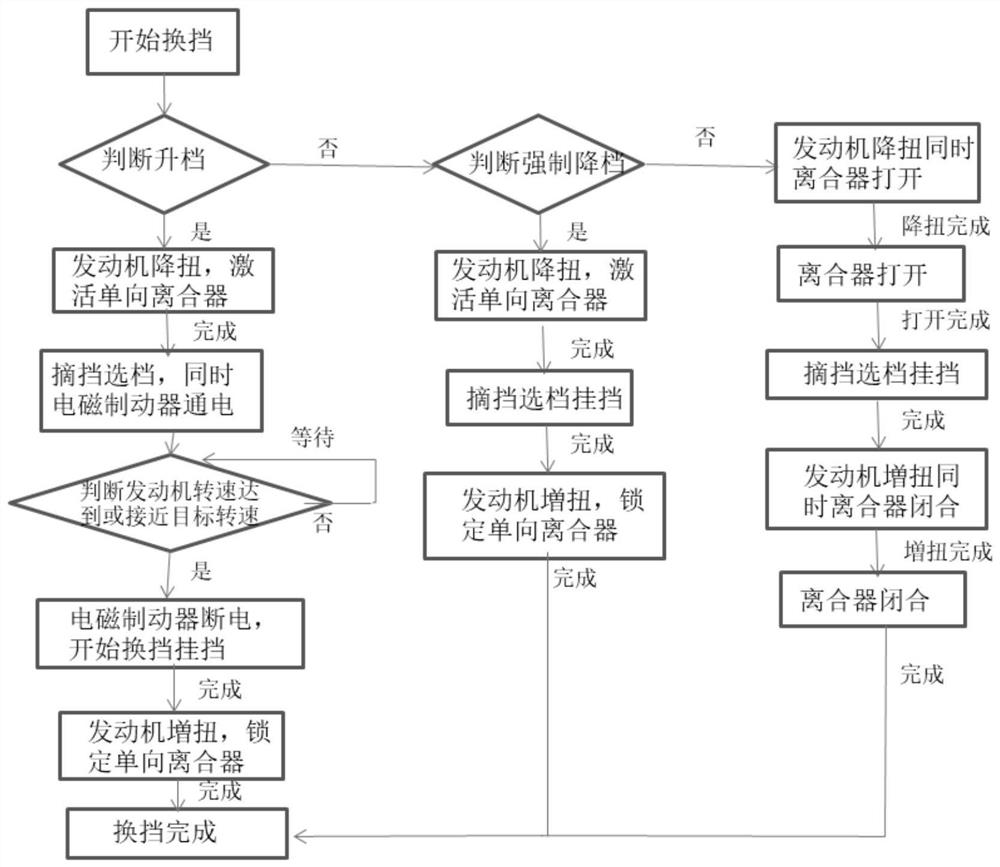

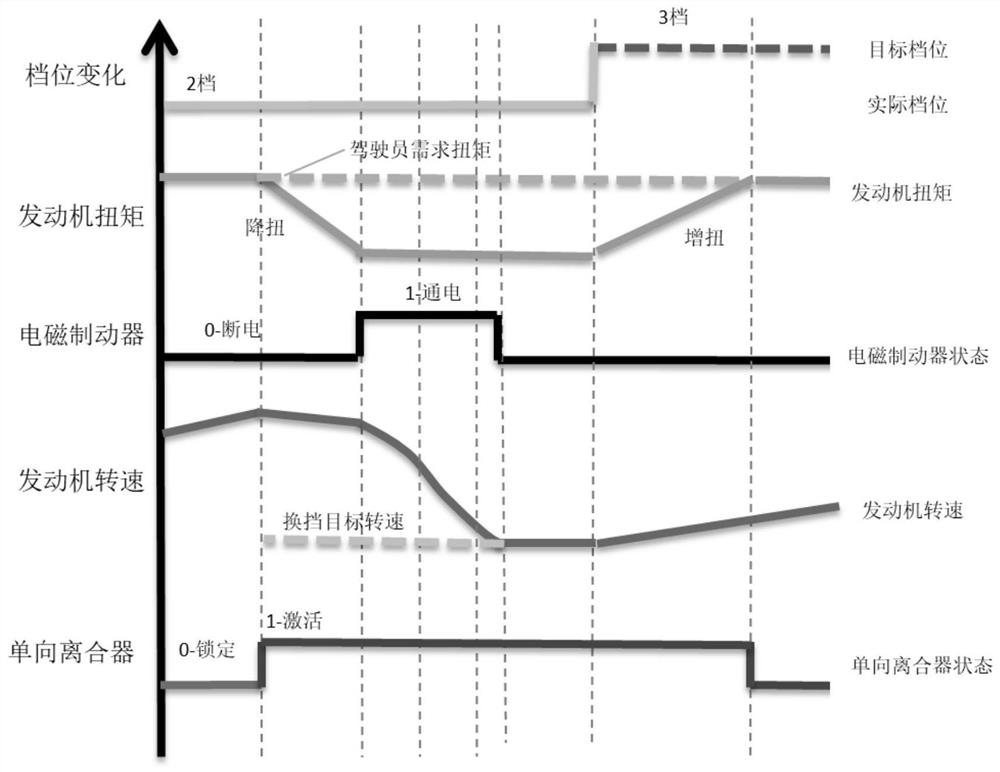

AMT gearbox gear shifting control system and control method

The invention provides an AMT gearbox gear shifting control system and a control method. The system comprises an electromagnetic brake, and an engine, a clutch assembly, an engine output shaft, an auxiliary gearbox and an AMT gearbox which are connected in sequence; the auxiliary gearbox comprises a one-way clutch and a gearbox input shaft; and the engine output shaft is connected with a gearbox input shaft in a co-rotating mode or connected with the gearbox input shaft through the one-way clutch. When an AMT gearbox needs to be upshifted or forcibly downshifted, the engine output shaft is connected with the gearbox input shaft through the one-way clutch, then gear shifting operation is conducted, in the gear shifting operation process, a clutch of the clutch assembly is kept in a closed state, and in the upshifting gear shifting process, the rotating speed of an engine crankshaft is adjusted in an auxiliary mode through the electromagnetic brake. According to the AMT gearbox gear shifting control system provided by the invention, the frustration caused by power interruption during gear shifting of a traditional AMT gearbox is eliminated, the gear shifting power interruption time of the AMT gearbox is greatly shortened, the gear shifting speed is increased, and the driving comfort is improved.

Owner:海博瑞德(北京)汽车技术有限公司

Planetary gearbox capable of directly shifting gears

InactiveCN101769365BFast gear shiftSimple designToothed gearingsGearing detailsModular unitGear wheel

The invention relates to a planetary gearbox capable of directly shifting gears. A cylindrical principal planetary gear at the input end and a cylindrical principal planetary gear at the output end are installed on a planetary rotating shaft through a connection rotating shaft which are fixedly connected with the cylindrical principal planetary gears at the input end and the output end; the cylindrical principal planetary gear at the input end is meshed with a cylindrical sun gear at the input end; the cylindrical principal planetary gear at the output end is meshed with a cylindrical sun gear at the output end; and the planet carrier of the mth planetary transmission modular unit at the front-half transmission mechanism is matched and connected with the planet carrier of the (m+1)th planetary transmission modular unit at the rear-half transmission mechanism through a one-way clutch, or a driving gear fixed on the planet carrier of the mth planetary transmission modular unit and a driven gear fixed on the planet carrier of the (m+1)th planetary transmission modular unit form a mesh transmission. The planetary gearbox are formed by connecting independent planetary transmission modular unit mechanisms in series, can obtain a high transmission ratio, can directly shift gears, and has the advantages of simple structure, low manufacturing cost and easy maintenance.

Owner:陈国庆

Gear shifting fluid control device of one-control-two-gear transmission and working method of gear shifting fluid control device

PendingCN114576348ASave installation spaceSmooth shiftingRoad transportGearing controlFluid controlControl engineering

The invention relates to a one-control-two-gear transmission gear shifting fluid control device and a working method thereof.The one-control-two-gear transmission gear shifting fluid control device comprises a shell, a driver, a planet row, a fluid control device and a clutch assembly, the fluid control device is arranged outside the shell and communicated with the driver in the shell, the driver comprises a piston, and the pushing end of the piston is connected with the clutch assembly; according to the gear shifting fluid control device of the one-control-two-gear transmission, complex TCU, sensors and proportional valves do not need to be matched, the influence of the response time of an air path control element is avoided, and the gear shifting speed is high.

Owner:福建中青传动科技有限公司

Quickly synchronized shifting method of gearbox

InactiveCN102330794AFast gear shiftReduce sync timeToothed gearingsControl engineeringControl theory

Owner:SUZHOU AMTF ROBOTS CO LTD

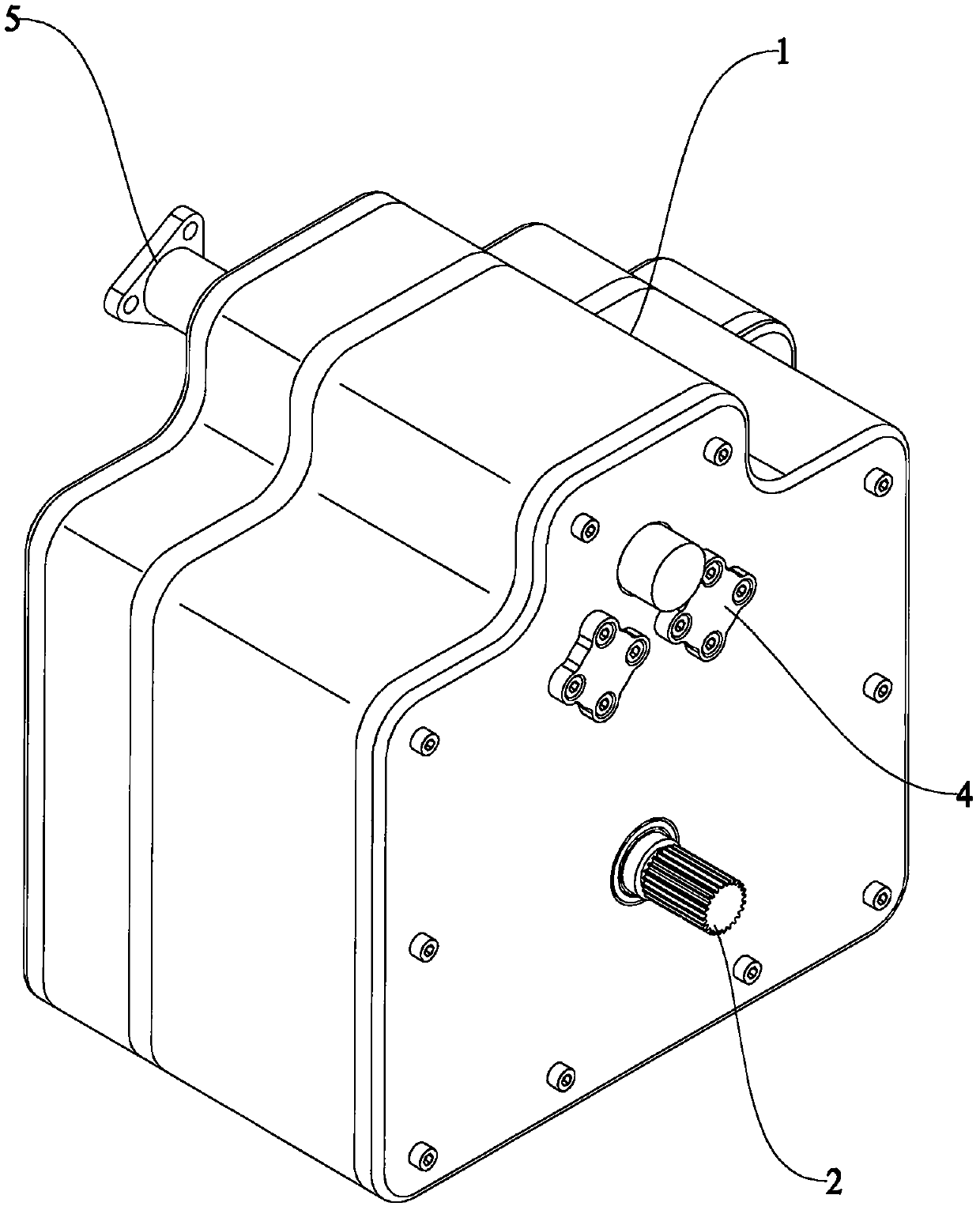

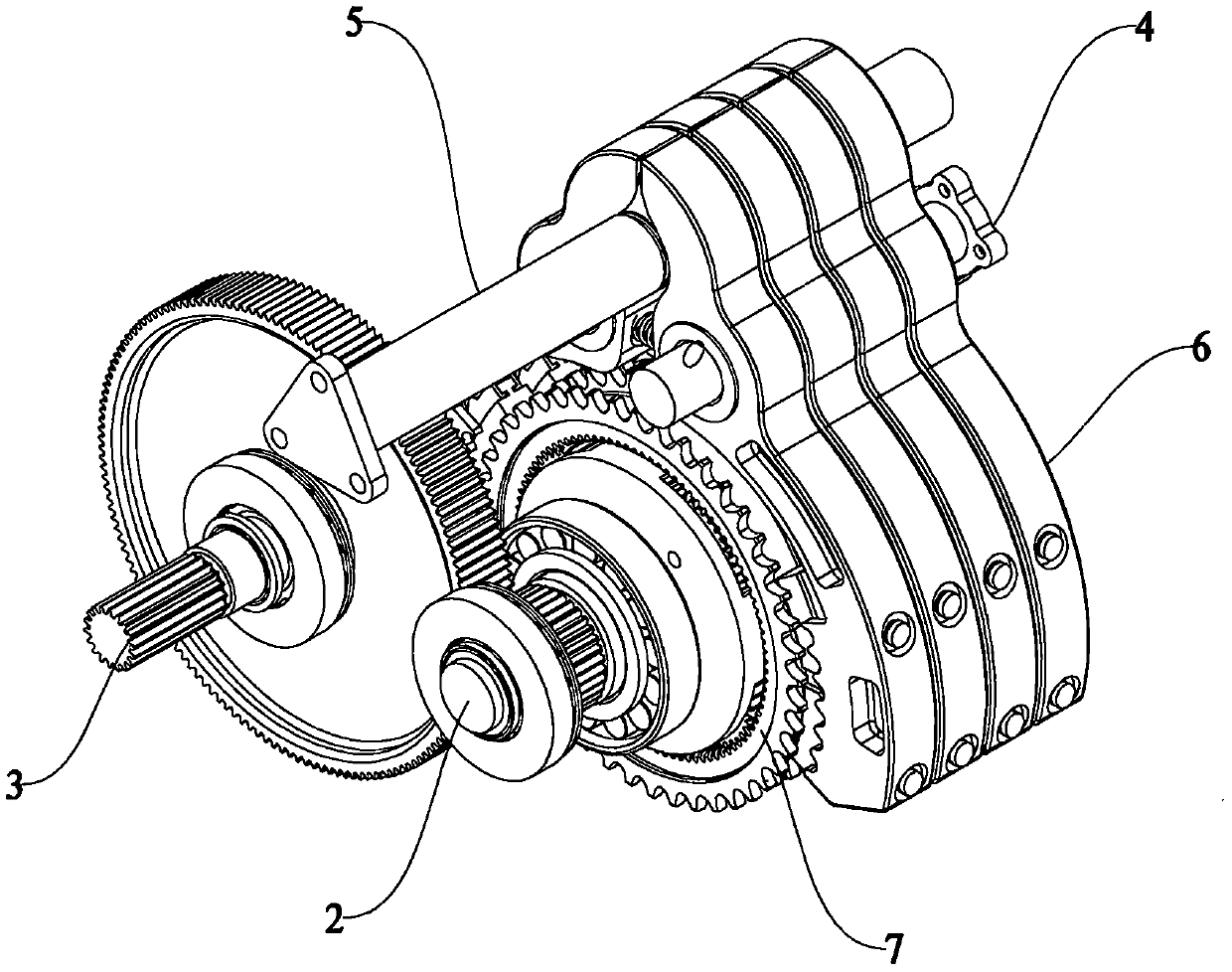

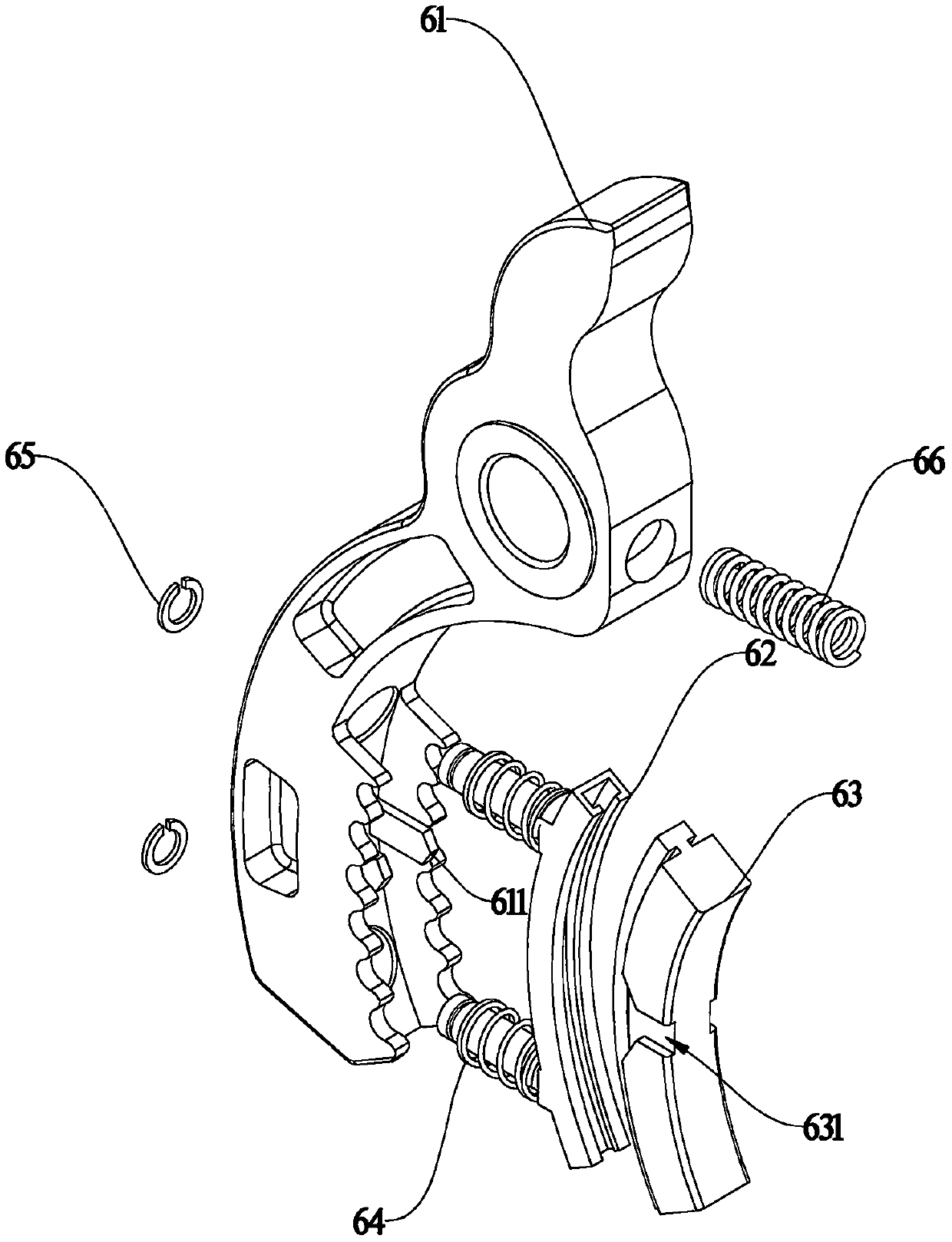

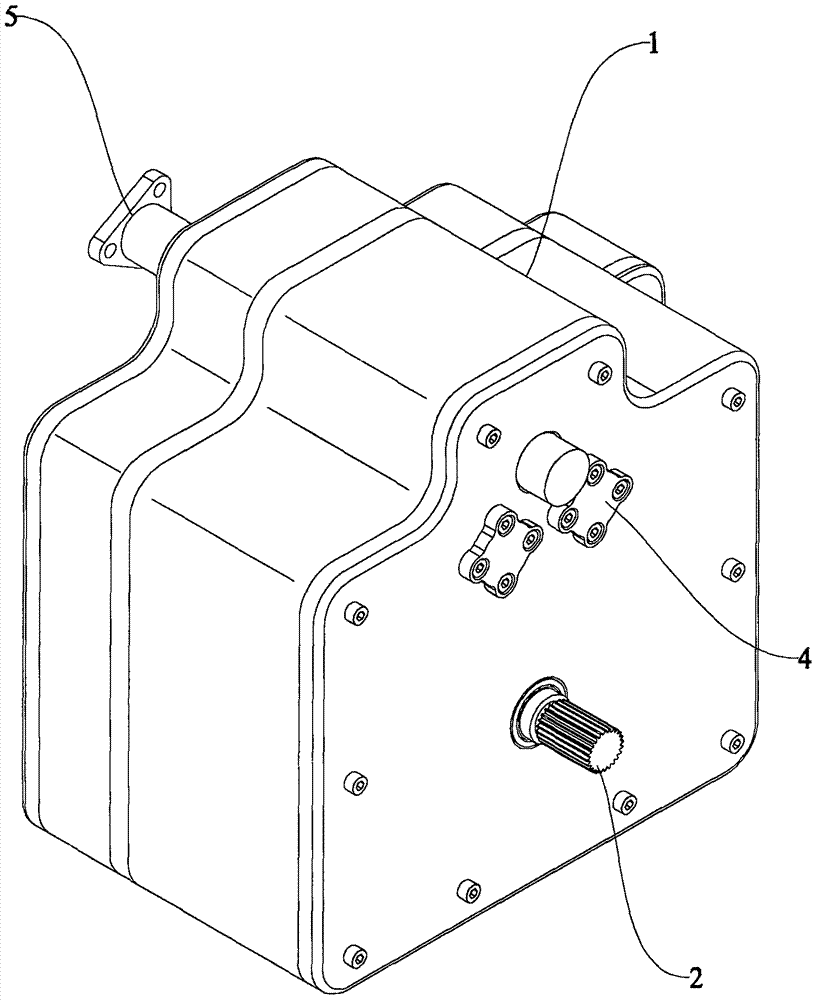

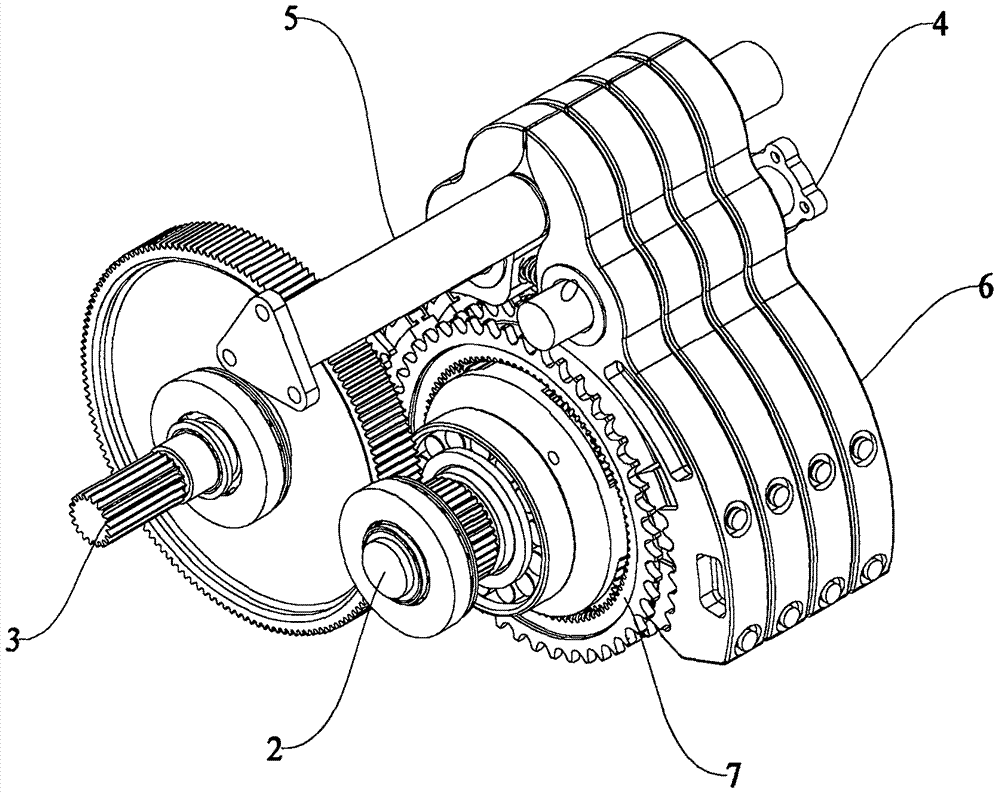

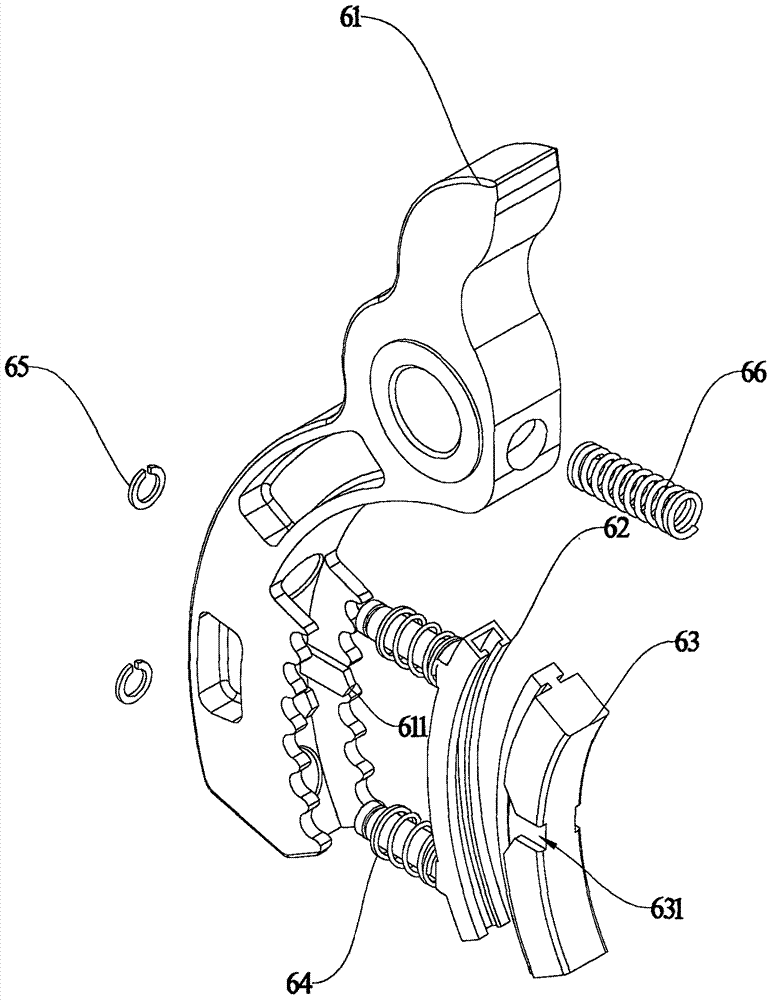

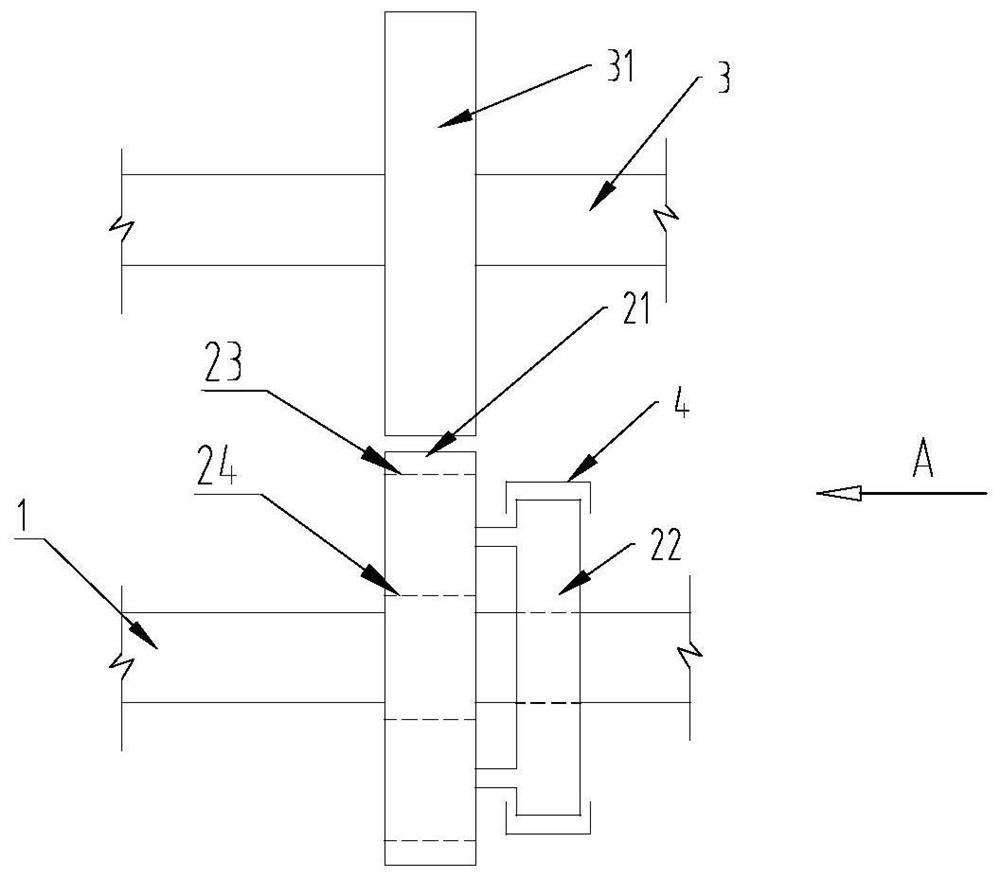

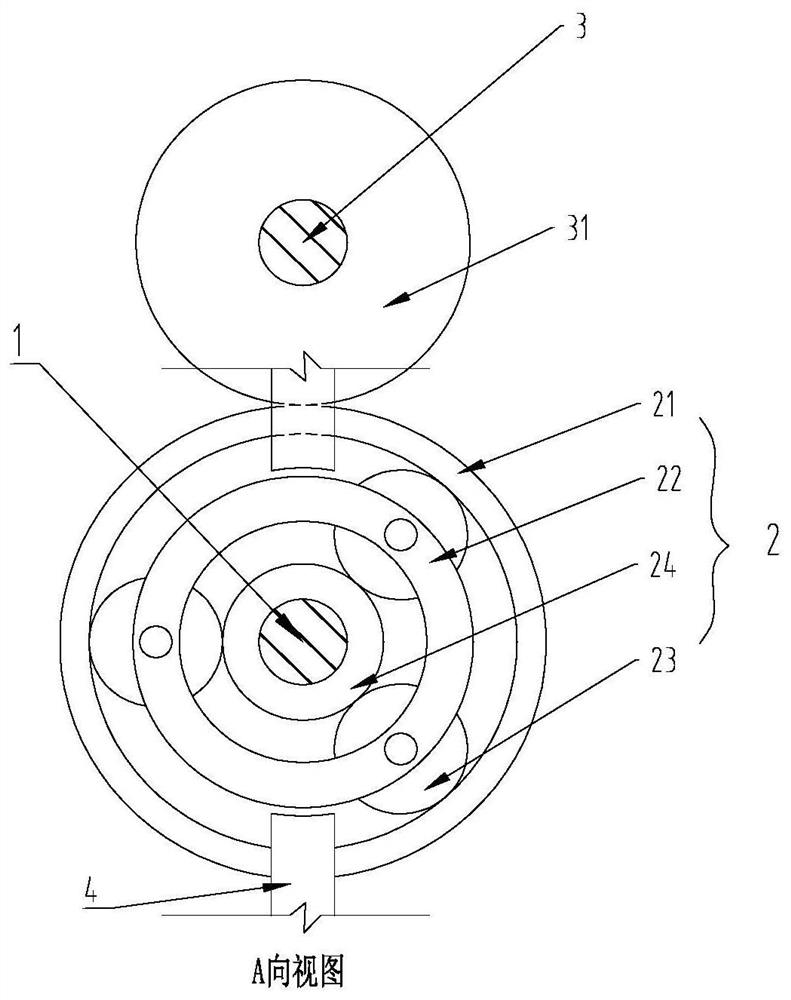

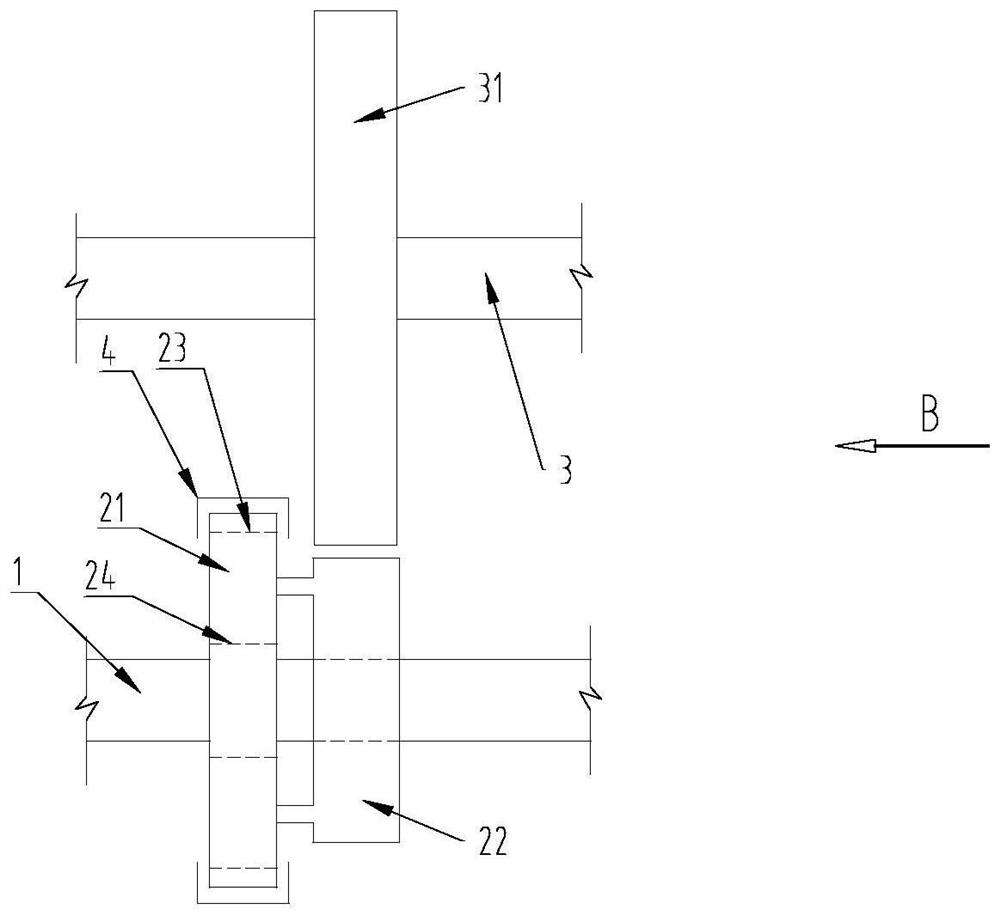

A transmission mechanism for a tractor

The invention discloses a speed change mechanism for a tractor. The speed change mechanism is characterized by comprising a shell, an input shaft, an output shaft, a clamp shaft, a gear shifting lever, a clamp assembly and a planet carrier assembly; the input shaft and the output shaft are respectively rotatably connected to the shell, and the input shaft drives the output shaft to rotate; the planet carrier assembly is arranged on the outer side of the input shaft and used for controlling the rotation speed of the input shaft; the clamp shaft is fixed to the shell; the clamp assembly is rotatably connected to the clamp shaft. The speed change mechanism which is simple in structure and stable in gear shifting is provided in order to solve problems of existing gear shifting mechanisms.

Owner:NINGBO BEIYE TRACTOR MFG

Variable speed mechanism for tractor

InactiveCN108006171ASimple structureReduce volumeToothed gearingsGearing controlCalipersControl theory

The invention provides a variable speed mechanism for a tractor. The variable speed mechanism for the tractor is characterized in that the variable speed mechanism comprises a shell body, an input shaft, an output shaft, a caliper shaft, a shift lever, a caliper assembly and a planet carrier assembly; the input shaft and the output shaft are correspondingly connected with the shell in a rotatablemode, and the input shaft drives the output shaft to rotate; the planet carrier assembly is arranged on the outside of the input shaft to control the rotation speed of the input shaft. The caliper shaft is fixedly arranged on the shell body. The caliper assembly is connected with the caliper shaft in a rotatable mode. The existing problem in the current shift variable speed mechanism is solved, and a variable speed mechanism with simple structure and stable shifting is provided.

Owner:余姚市奥祥轴承有限公司

A double-input-shaft five-speed ratio transmission mechanism

ActiveCN108223744BCompact structureReduce weightToothed gearingsTransmission elementsGear driveGear wheel

Owner:重庆红岭动力技术有限公司

Hydraulic controlled clutch and speed variator

PendingCN110630653AEasy to separateAchieve disengagement/engagementFluid actuated clutchesToothed gearingsBrake shoePiston

The invention provides a hydraulic controlled clutch and a speed variator. The clutch comprises a brake drum and brake assemblies, wherein the brake assemblies are placed inside the brake drum, and the brake assemblies comprise a brake base disc, brake branch pumps, a hydraulic pipeline, brake shoes, brake shoe baffles, support pins and return springs; four brake shoes are provided which are correspondingly connected with the supporting pins along the edge of the brake base disc in a pivoted mode, the brake shoe baffles are fixed on the brake base disc and make contact with the inner side faces of the brake shoes to limit the brake shoes; and the outer side faces of the brake shoes are separated from / make contact with the inner side face of the brake drum so as to realize the separation / connection between the brake shoes and the brake drum, each brake branch pump is provided with two pistons, the end parts of the pistons abut against the end parts, far away from one ends of the supporting pins, of the brake shoes, the pistons are moved through the hydraulic driving in the hydraulic pipeline, and the pistons push the brake shoes to expand outwards to realize the separation / connection between the brake assemblies and the brake drum. According to the technical scheme, the transmission stability of the clutch can be improved.

Owner:尚尔航

Ladder-like n-gear wet clutch structure

ActiveCN111810552AImprove carrying capacityImprove cooling effectFluid actuated clutchesToothed gearingsGear driveGear wheel

The invention discloses a ladder-like n-gear wet clutch structure. The ladder-like n-gear wet clutch structure is characterized in that the ladder-like n-gear wet clutch structure comprises a shell, an oil conveying pipe, a piston, a sealing ring, a stop washer, a reset spring, a clutch disc, gear shafts, gear tooth rings and a gear transmission structure; and movement of the piston is hydraulically controlled, the reset speed of the piston is increased through the reset spring, the sealing ring prevents leakage of hydraulic oil, the position of the clutch disc is fixed through the stop washer, the gear shafts are all hollow shafts and are nested layer by layer, and the gear shafts are fixedly connected with the gear tooth rings. The ladder-like n-gear wet clutch structure is large in structural-load-carrying capacity, good in heat-dissipating property and wide in application range; by adopting the ladder-like shell for shape design, the adopted space is saved, and the structure is compact; and by adopting a modular thought, sustainable extension is achieved, and application prospects are wide.

Owner:HEFEI UNIV OF TECH

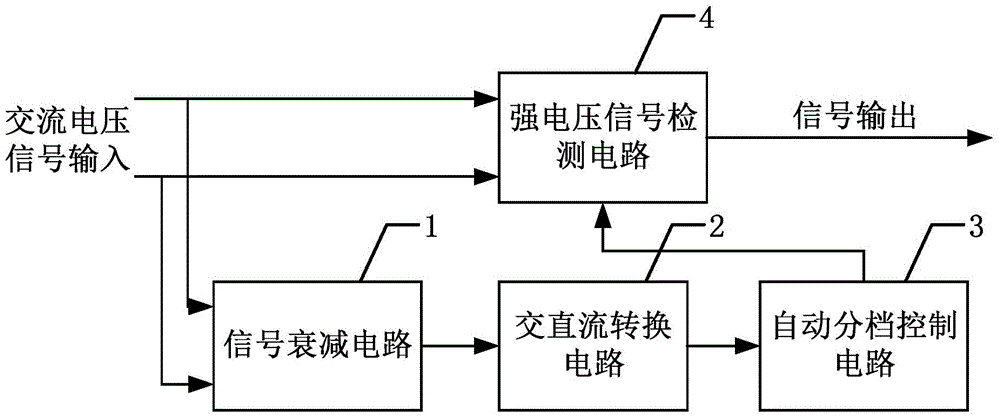

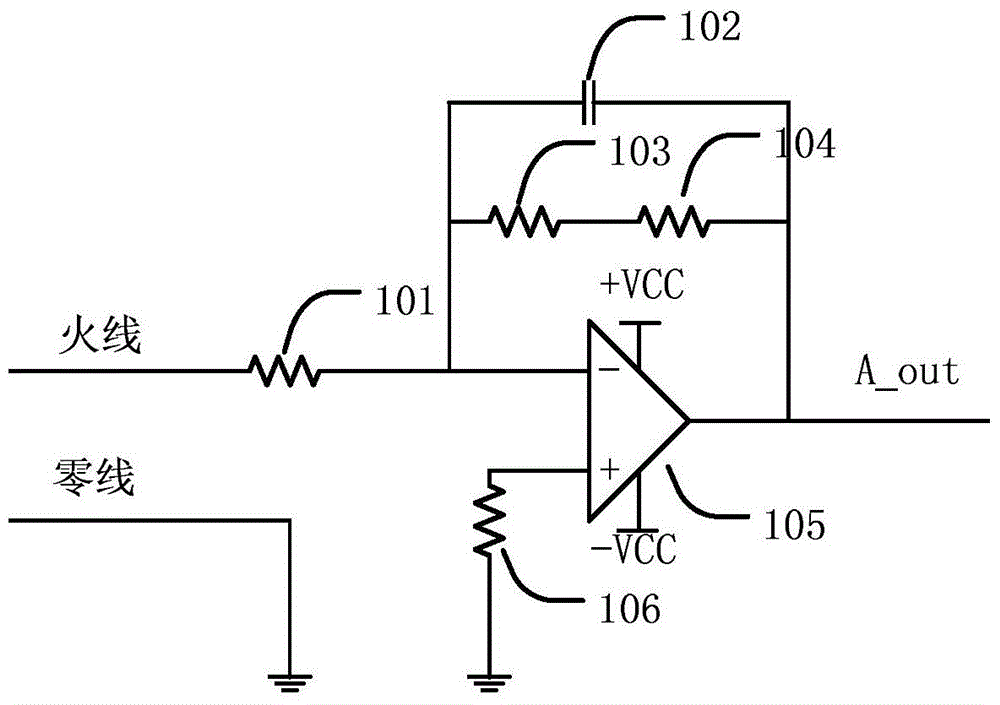

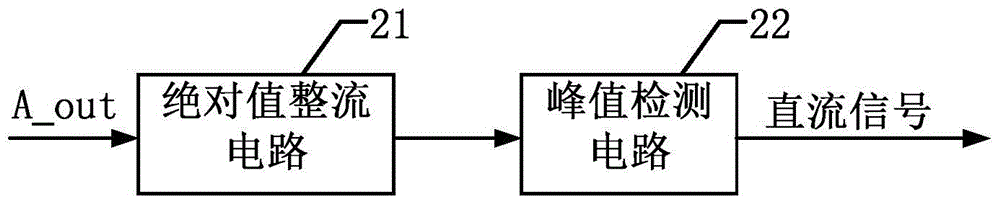

A wide voltage power signal voltage detection device

InactiveCN104316755BRealize detectionFast gear shiftMeasurement using ac-dc conversionUltrasound attenuationControl signal

The invention discloses a wide-voltage power signal voltage detection device, which includes a signal attenuation circuit, an AC-DC conversion circuit, an automatic classification control circuit and a strong voltage signal detection circuit, and the AC voltage signal is passed through the signal attenuation circuit and the AC-DC conversion circuit. After attenuation, it is converted into a DC signal. The automatic stepping control circuit includes N-1 groups of amplification / attenuation devices and voltage comparators. Each amplification / attenuation device is amplified / attenuated according to the reference voltage value of the corresponding voltage comparator and the corresponding voltage range. Multiples, each amplification / attenuation device receives the DC signal for amplification / attenuation processing, the voltage comparator compares the attenuated DC signal with the reference voltage signal, outputs the control signal, and realizes classification, and the strong voltage signal detection circuit is based on the control signal. Set the current gear, and detect the AC voltage signal to obtain the voltage value. The invention can realize voltage detection of wide voltage, adopts pure hardware shifting, has fast shifting speed and high reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

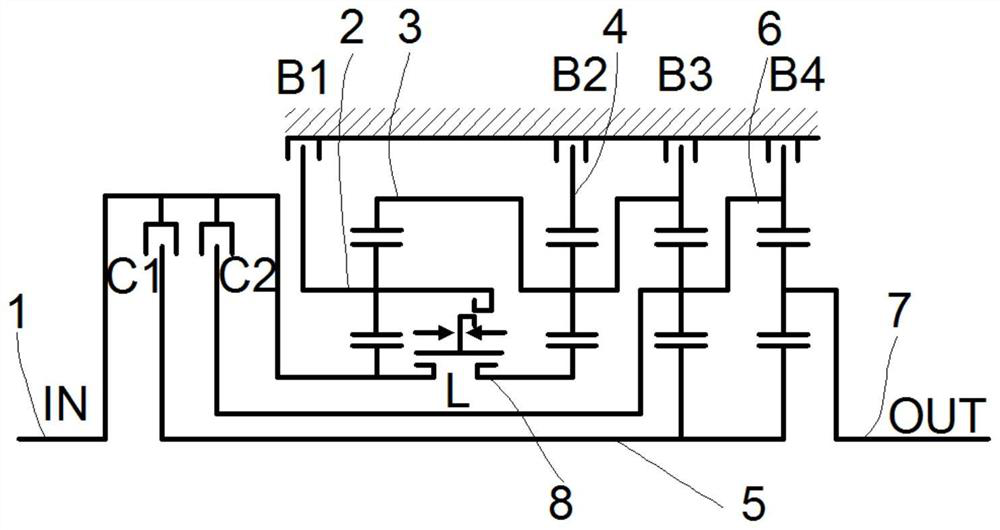

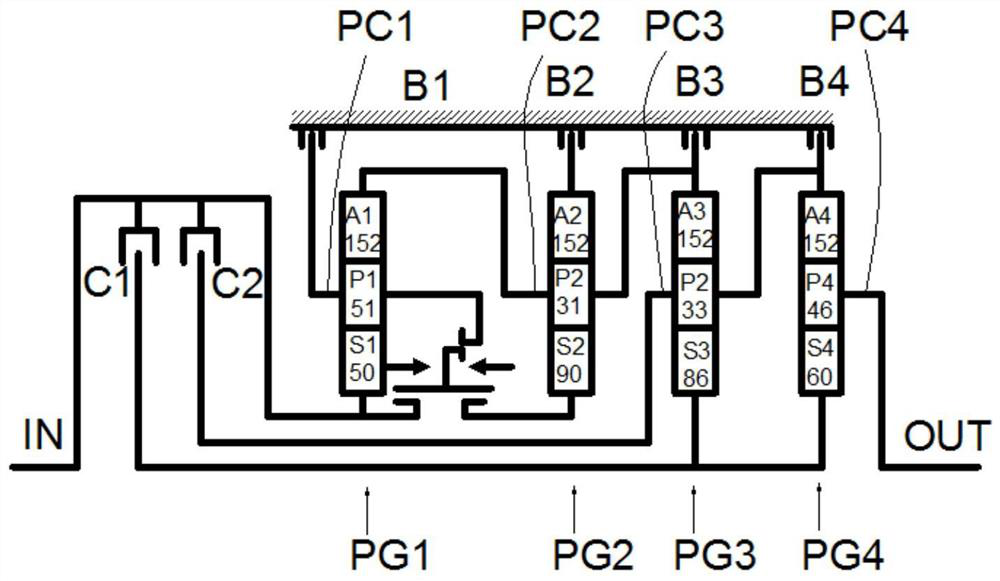

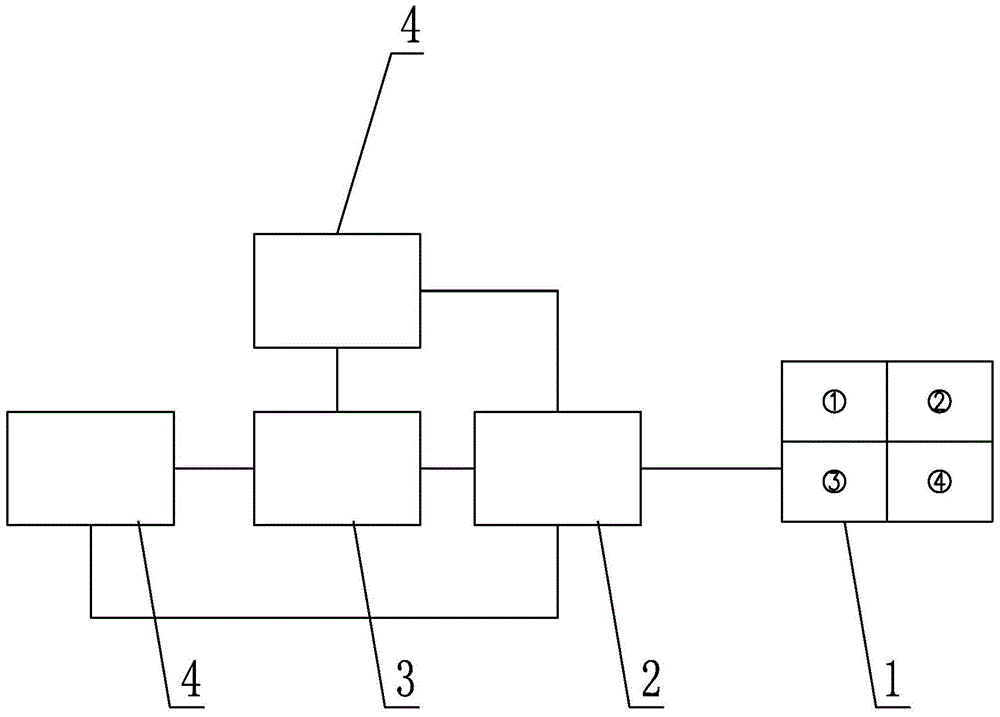

Modularized speed control system

PendingCN113007294AAchieve smoothnessEasy to slipToothed gearingsTransmission elementsSpeed control systemGear wheel

A modularized speed control system belongs to the technical field of automobile speed control systems and comprises a planet wheel assembly. The planet wheel assembly is coupled with a brake mechanism, an input shaft, an output shaft and an output gear to form a module unit. The input shaft of the module unit is coupled with the output gear through the planet wheel assembly, power is transmitted to the output shaft by controlling the action of the brake mechanism, power transmission is achieved, and speed transmission is achieved. The planet wheel assembly in the module unit is coupled with the brake mechanism, the input shaft and the output gear in various manners to form different modules for different combinations, so that a whole with a simple structure is formed, the purposes of transmitting power and increasing or decreasing torque are achieved, and then speed transmission and reversing are achieved. The system is stable and reliable in performance, can realize time linear adjustment in the process of synchronizing the rotating speed of the output shaft to the rotating speed of the input shaft by controlling the action time of the brake mechanism, can also realize rapid switching between forward and reverse rotation, and has the characteristic of large transmission torque.

Owner:杨阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com