Planetary gearbox capable of directly shifting gears

A planetary gear and gearbox technology, which is applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problems of excessive variation of the common normal, difficult processing of the inner gear ring, difficult processing and manufacturing, etc. To achieve the effect of easy processing, low cost, simple design and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

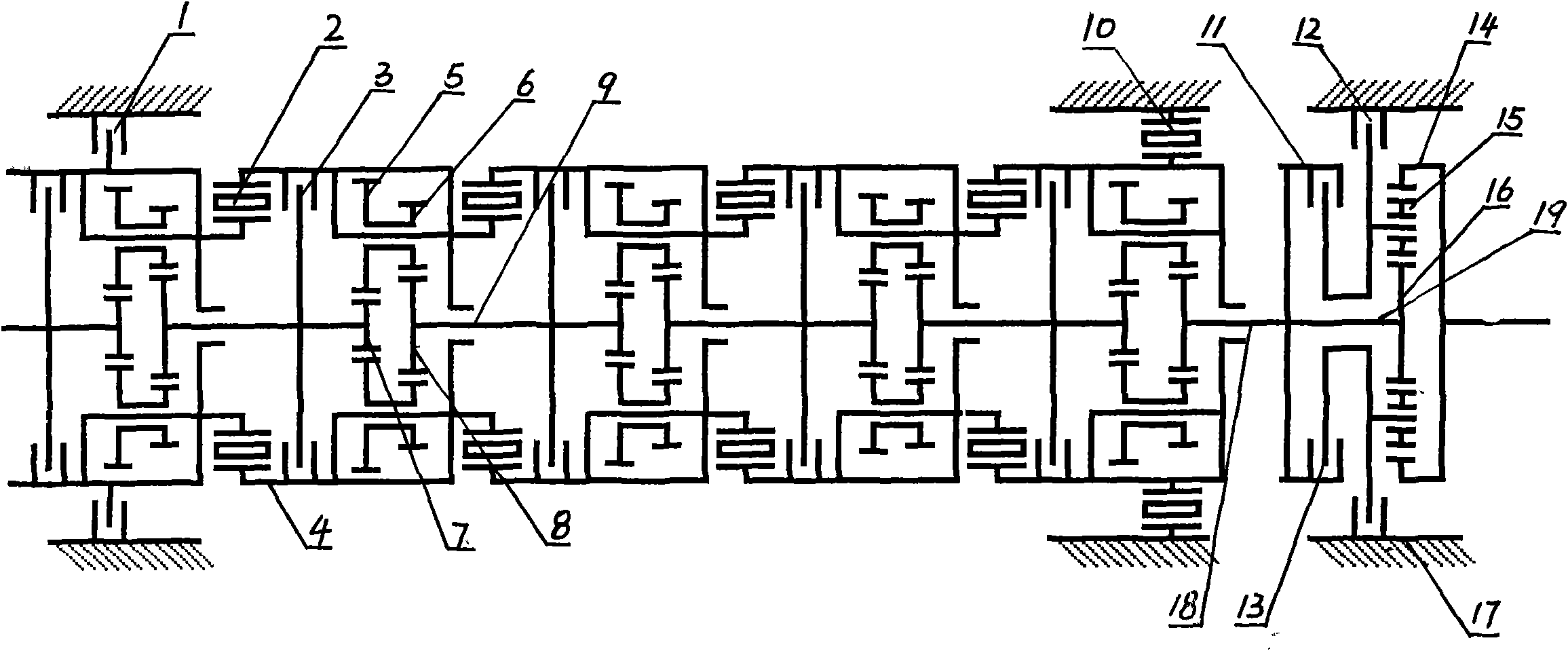

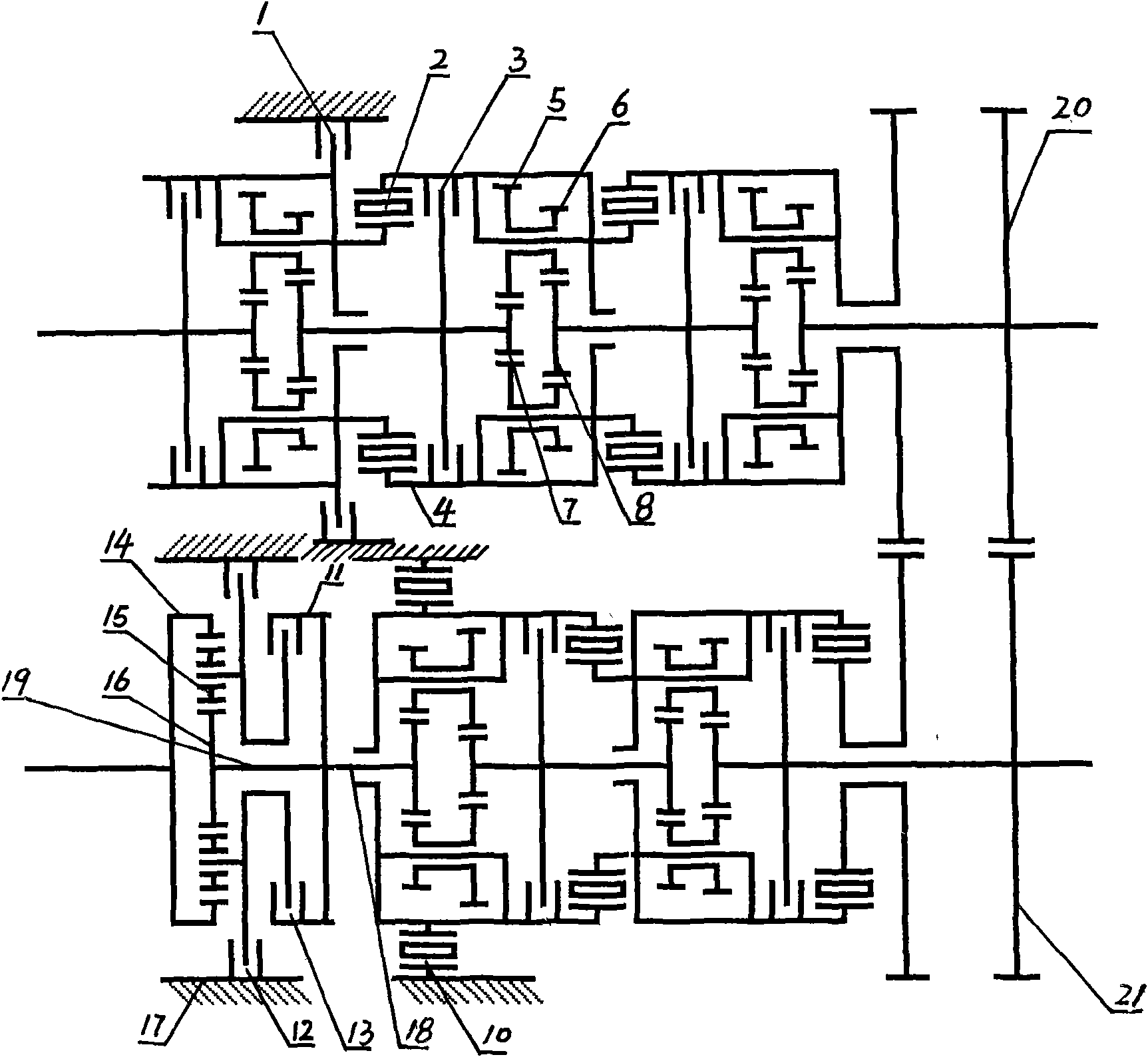

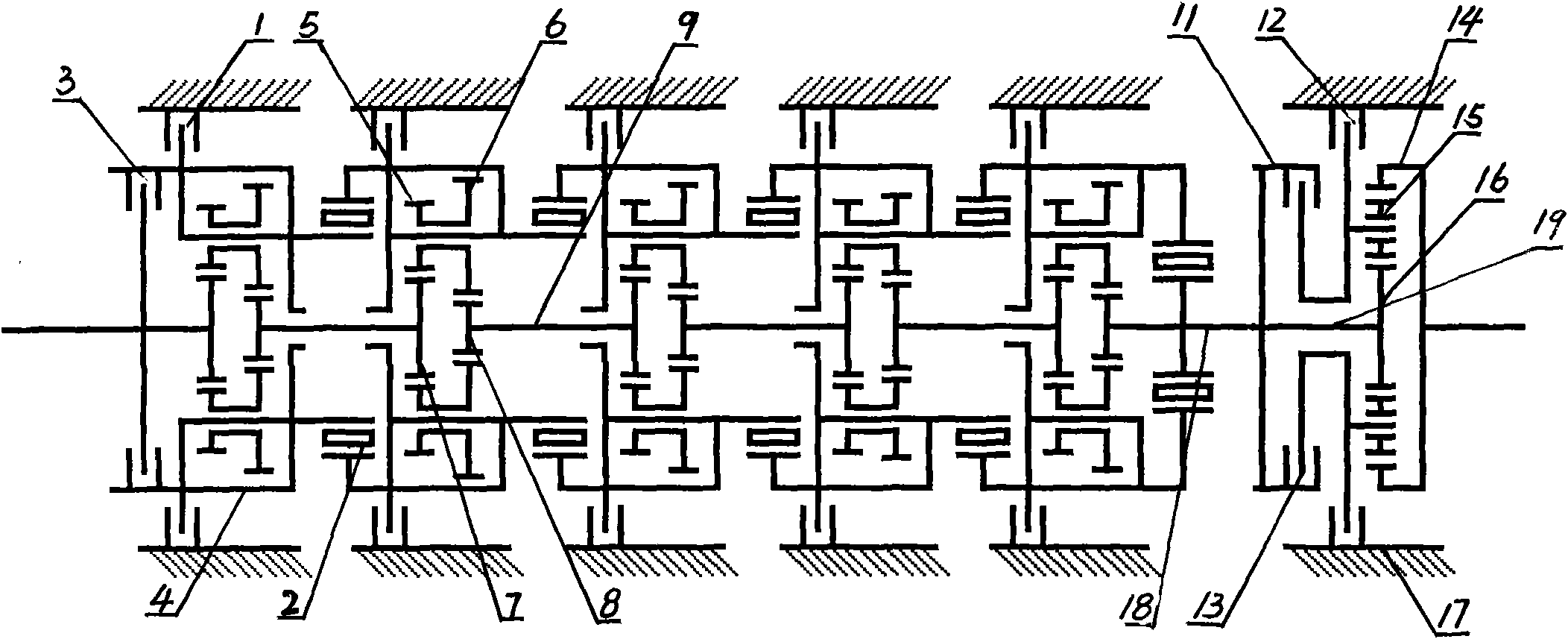

[0015] A planetary gear gearbox that can be directly shifted, including a gearbox housing, a cylindrical sun gear 7 at the input end and a cylindrical sun gear 8 at the output end that are parallel to the rotating shaft to form a sun gear system, and the sun gear 7 at the input end The sun gear 8 located at the output end is driven by the cylindrical planetary gear. The revolution axis of the cylindrical planetary gear is parallel to the sun gear 7 and the sun gear 8. The cylindrical planetary gear is installed on the planet carrier 4, and the planet carrier 4 and the sun gear 7. The sun gear 8 is coaxially installed. The cylindrical planetary gear is at least a pair consisting of a cylindrical main planetary gear 5 at the input end and a cylindrical main planetary gear 6 at the output end. The cylindrical main planetary gear 5 at the input end and the output end The cylindrical main planetary gear 6 at the end is mounted on the planetary shaft through its fixed connection shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com