Gear shifting fluid control device of one-control-two-gear transmission and working method of gear shifting fluid control device

A technology of fluid control device and transmission, which is applied in the direction of transmission control, clutch, one-way clutch, etc., which can solve the problems of long shift time, shift shock, frustration, and transmission damage, and achieve stable shift effect and reduce faults point, the effect of fast shifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

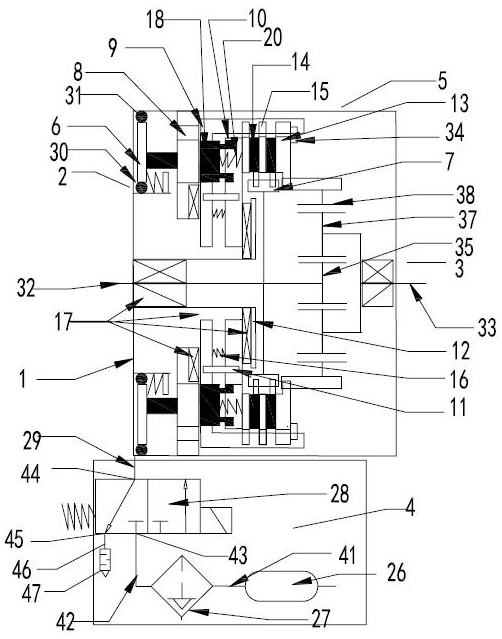

[0022] like Figures 1~5 As shown, the shifting fluid control device of a one-control two-speed transmission includes a casing 1, a driver 2, a planetary row 3, a fluid control device 4, and a clutch assembly 5. The fluid control device is outside the casing but communicates with the driver inside the casing. , the drive includes a piston 6, the pushing end of which is connected with the clutch assembly, the clutch assembly is slidably connected through the clutch drum and the ring gear of the planetary row, and is fixedly connected with the sun gear through the clutch hub.

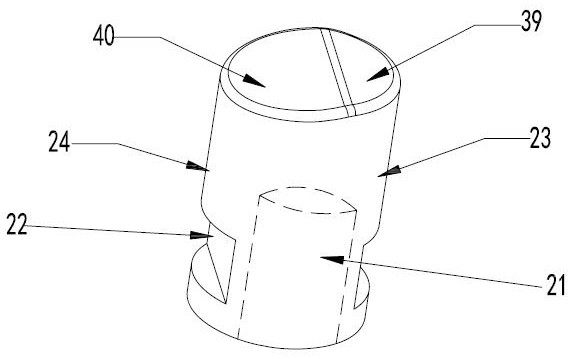

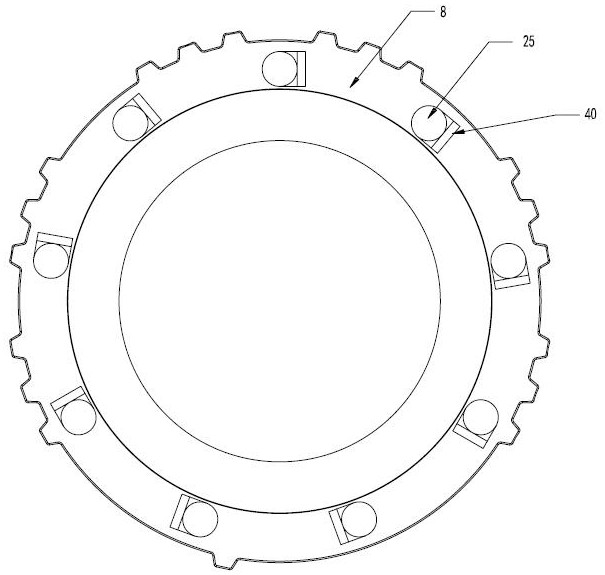

[0023] In the embodiment of the present invention, the right end of the piston is the push end, and the right end of the piston is provided with a ratchet wheel 8 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com