Gearbox

A gearbox and box technology, which is applied to transmission parts, components with teeth, belts/chains/gears, etc. Effect of reaction time, reduced friction loss, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

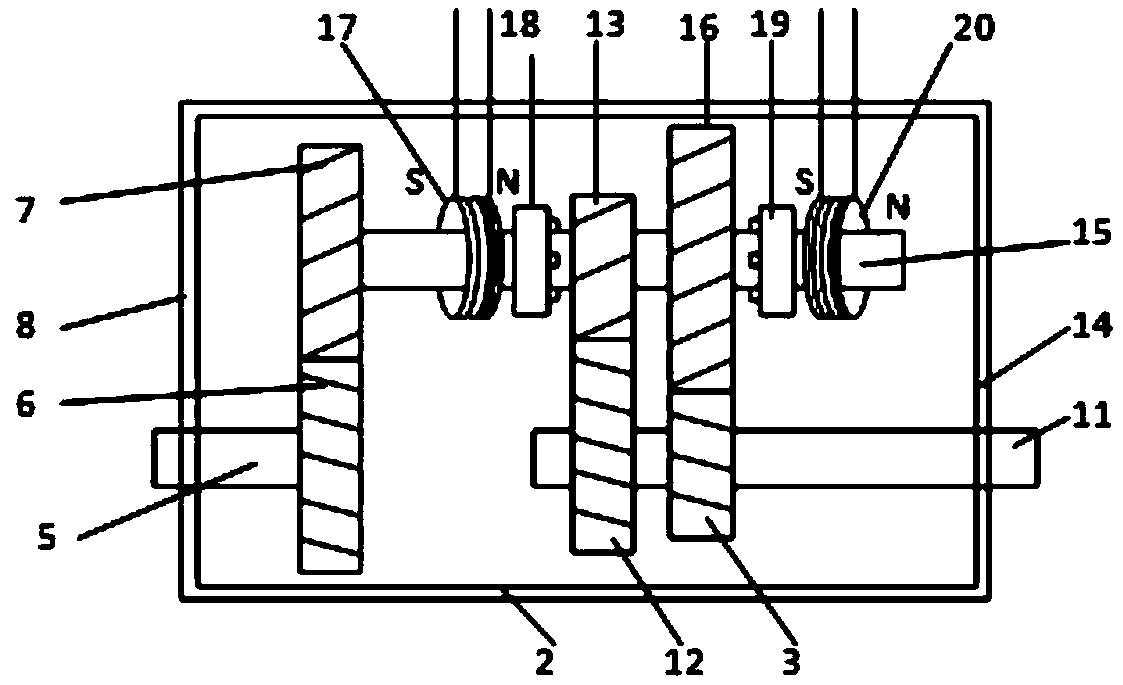

Embodiment 1

[0034] A gearbox, comprising a gearbox case 2, a power input shaft 5, an intermediate shaft 15 and a power output shaft 11 are pierced inside the gearbox case, and the gears on the intermediate shaft 15 are respectively connected to the gears of the power input shaft 5 and the power The high gear 3 of the output shaft 11 meshes with the low gear 12, the first solenoid 17 and the second solenoid 20 are arranged on the intermediate shaft 15, and the first solenoid 17 and the intermediate shaft pinion 18, between the second solenoid 20 and the intermediate shaft gear 16, a synchronizer is respectively arranged;

[0035] Described gearbox housing 2, power input shaft 5, intermediate shaft 15, power output shaft 11 and all gears are all made of non-ferromagnetic materials, and the synchronizer is made of permanent magnets, consisting of the first solenoid 17 and the second The two solenoids 20 control the synchronizer to move on the intermediate shaft 15 , and a switch circuit for ...

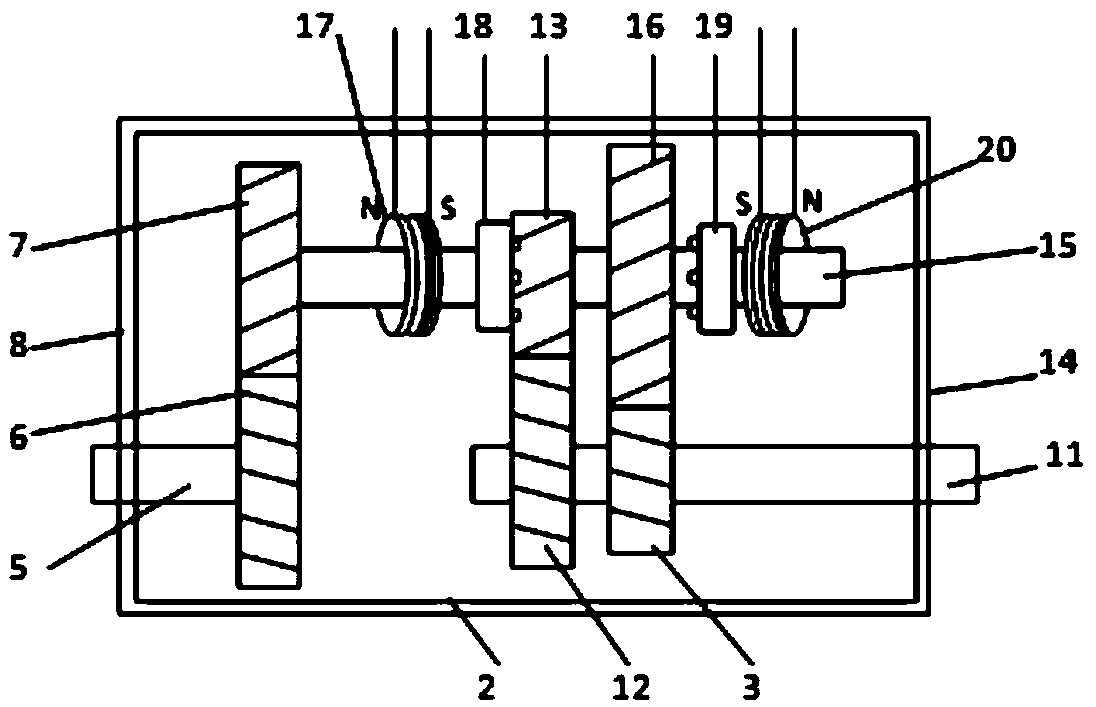

Embodiment 2

[0039] A gearbox, comprising a gearbox case 2, a power input shaft 5, an intermediate shaft 15 and a power output shaft 11 are pierced inside the gearbox case, and the gears on the intermediate shaft 15 are respectively connected to the gears of the power input shaft 5 and the power The high gear 3 of the output shaft 11 meshes with the low gear 12, the first solenoid 17 and the second solenoid 20 are arranged on the intermediate shaft 15, and the first solenoid 17 and the intermediate shaft pinion 18, between the second solenoid 20 and the intermediate shaft gear 16, a synchronizer is respectively arranged;

[0040] Described gearbox housing 2, power input shaft 5, intermediate shaft 15, power output shaft 11 and all gears are all made of non-ferromagnetic materials, and the synchronizer is made of permanent magnets, consisting of the first solenoid 17 and the second The two solenoids 20 control the synchronizer to move on the intermediate shaft 15 , and a switch circuit for ...

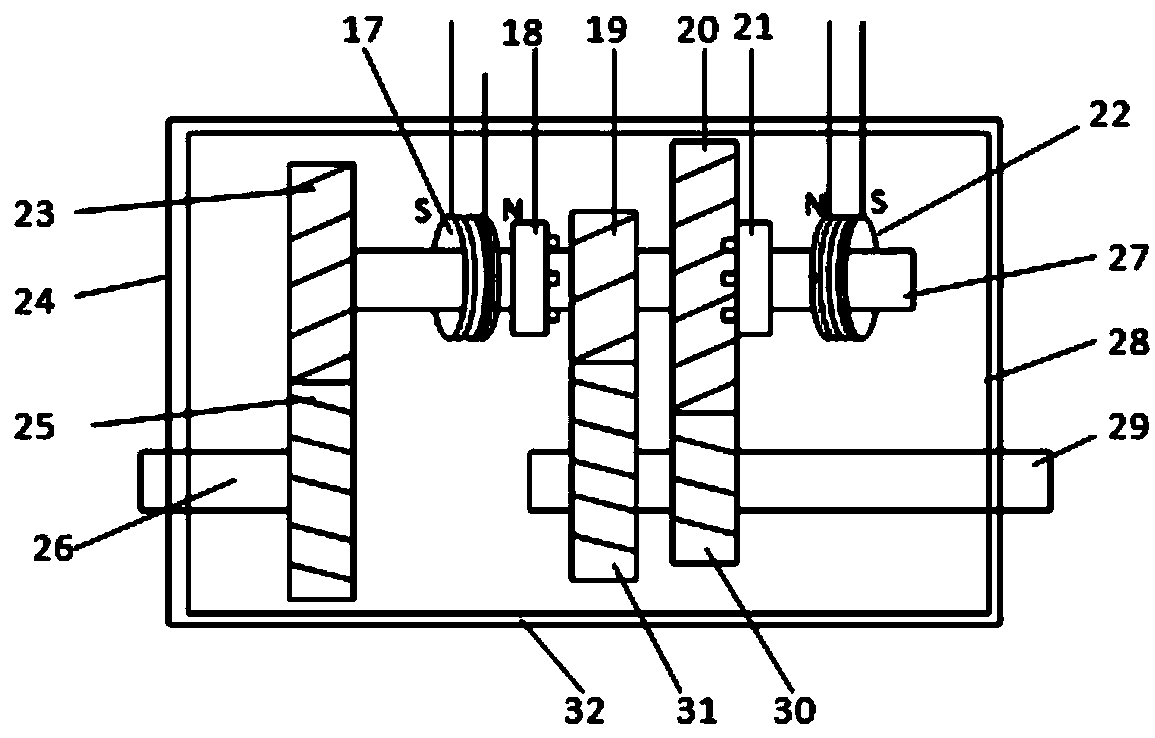

Embodiment 3

[0047] A gearbox, comprising a gearbox case 2, a power input shaft 5, an intermediate shaft 15 and a power output shaft 11 are pierced inside the gearbox case, and the gears on the intermediate shaft 15 are respectively connected to the gears of the power input shaft 5 and the power The high gear 3 of the output shaft 11 meshes with the low gear 12, the first solenoid 17 and the second solenoid 20 are arranged on the intermediate shaft 15, and the first solenoid 17 and the intermediate shaft pinion 18, between the second solenoid 20 and the intermediate shaft gear 16, a synchronizer is respectively arranged;

[0048] Described gearbox housing 2, power input shaft 5, intermediate shaft 15, power output shaft 11 and all gears are all made of non-ferromagnetic materials, and the synchronizer is made of permanent magnets, consisting of the first solenoid 17 and the second The two solenoids 20 control the synchronizer to move on the intermediate shaft 15 , and a switch circuit for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com