Automatic manual speed changer and speed change control mechanism thereof

A technology of manual transmission and operating mechanism, which is applied in the field of vehicle transmission and can solve problems such as complex structure and slow shifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

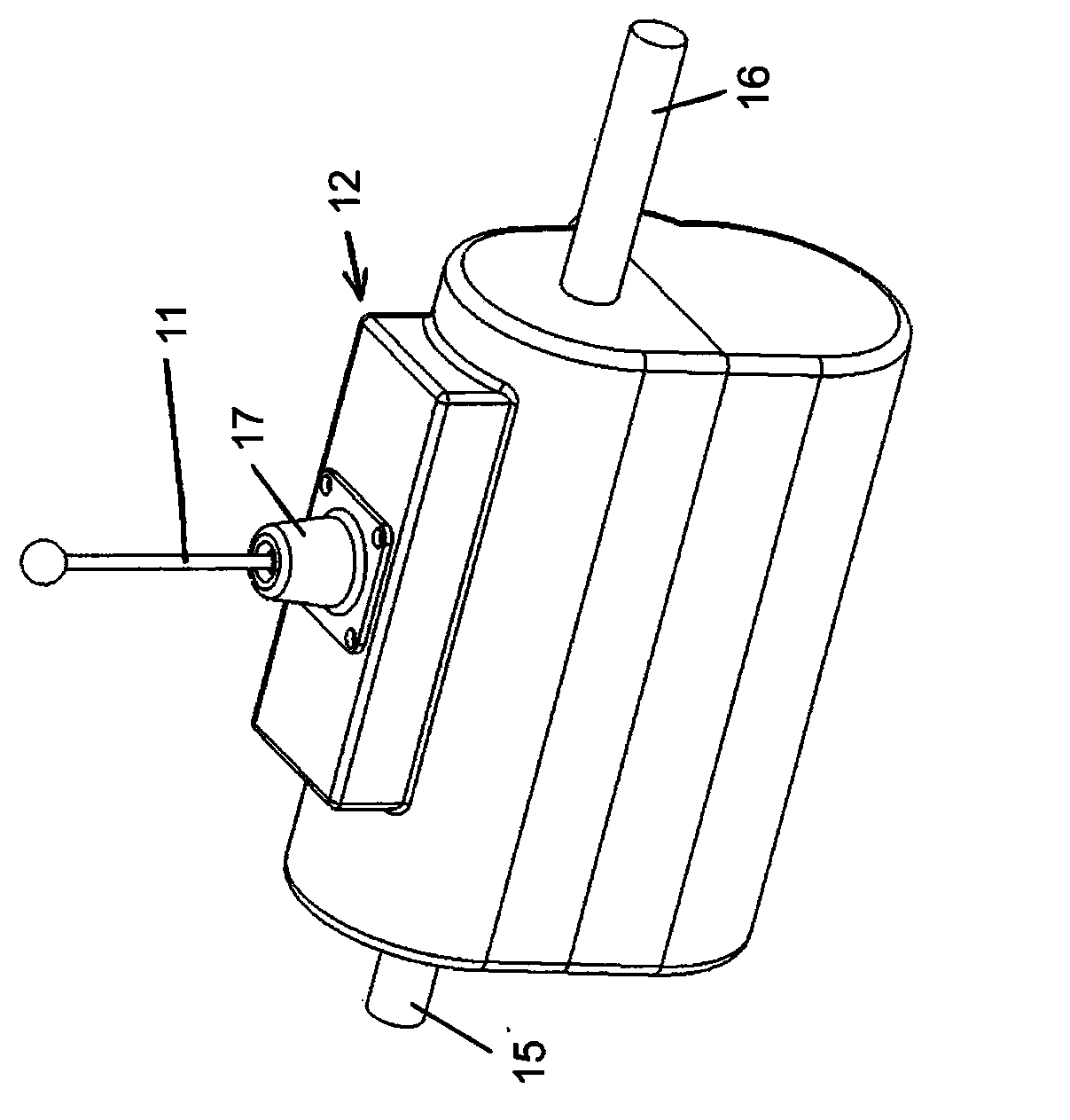

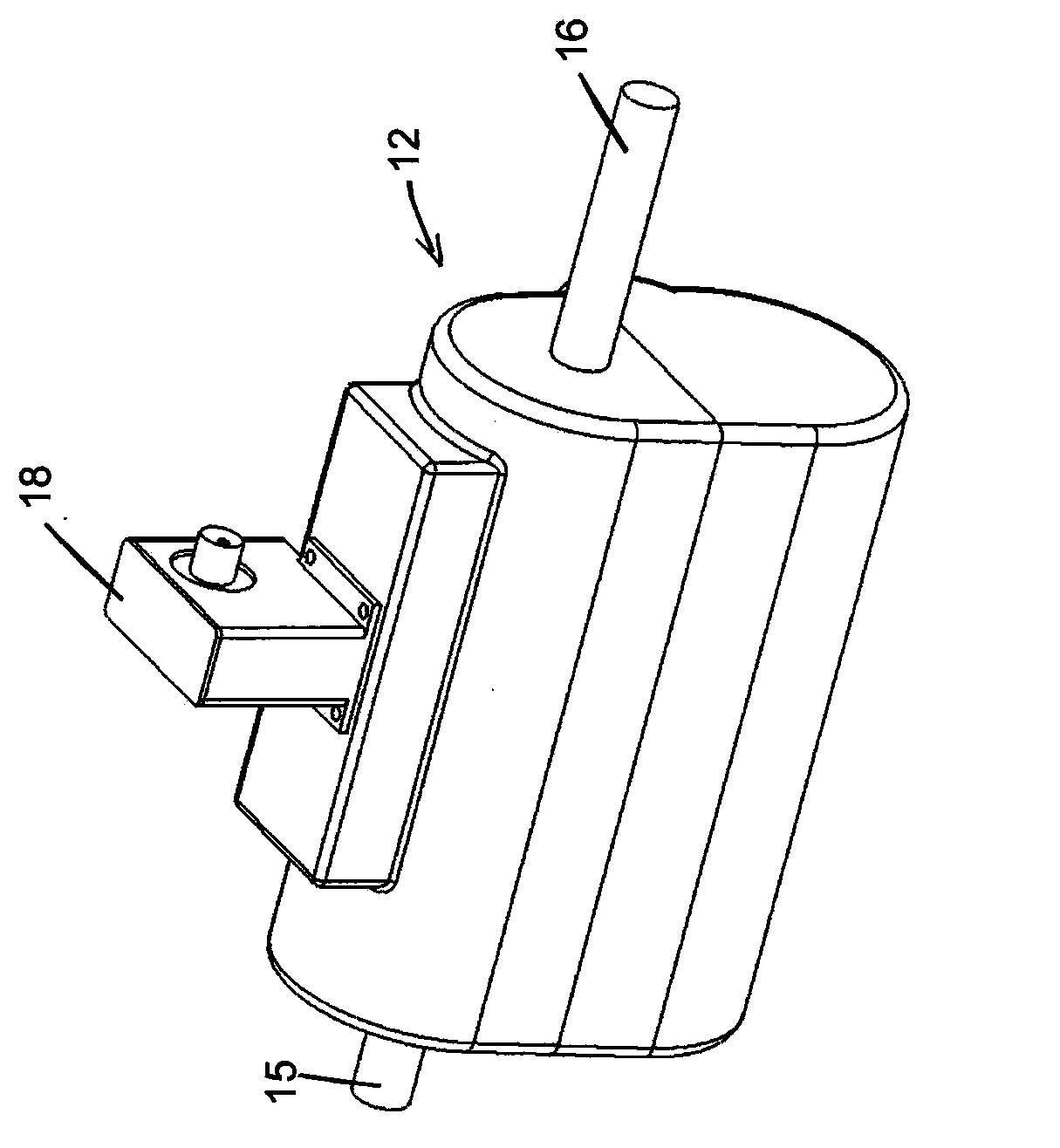

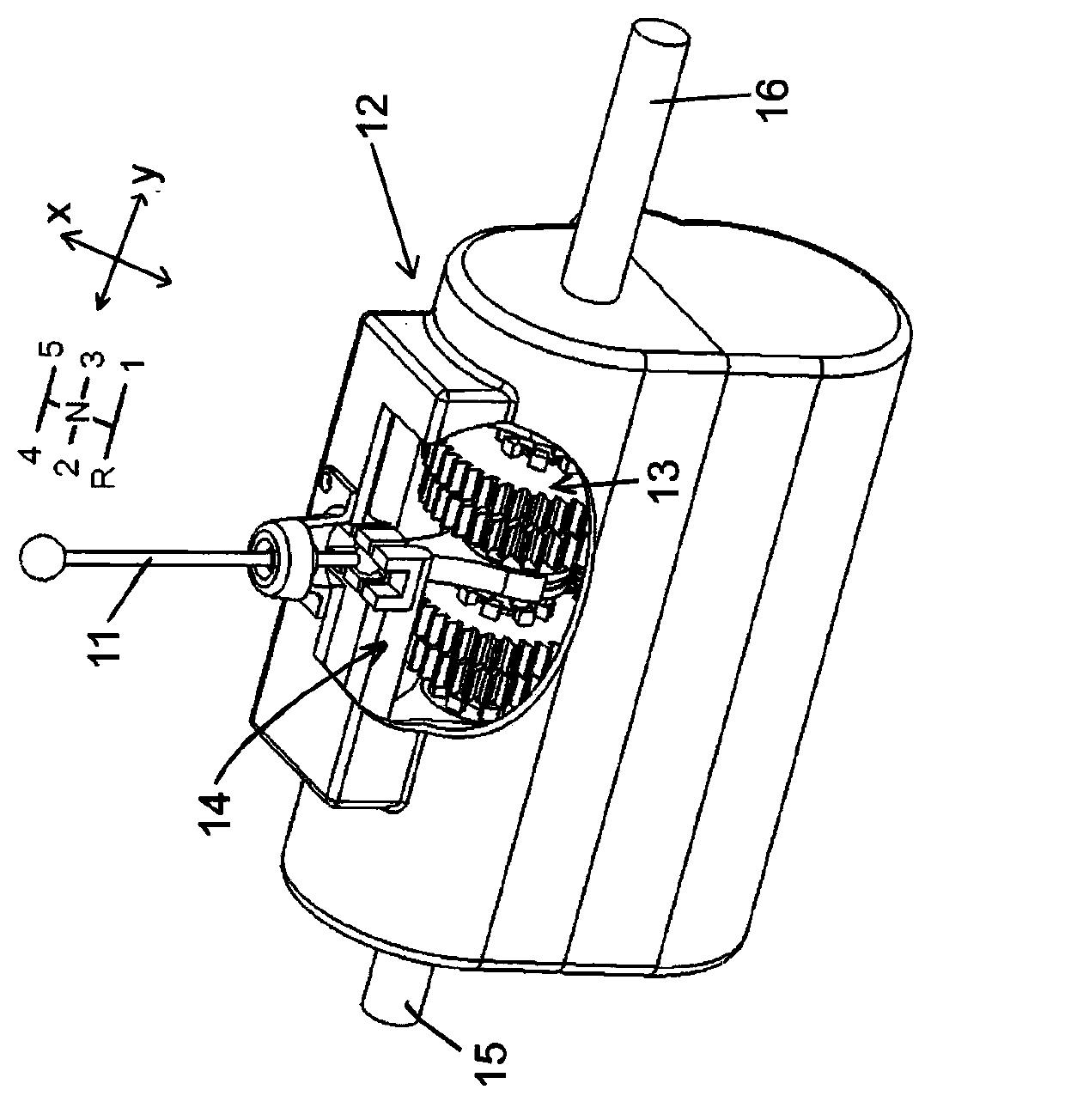

[0023] The automatic manual transmission and its transmission operating mechanism according to the present invention will be described below with reference to the accompanying drawings. The automatic manual transmission according to the present invention is also referred to as a manual transmission (for example, Figure 1A and 1B The typical traditional manual transmission shown in the figure) is based on the modification, and has the same gear-type transmission mechanism as the manual transmission, but the transmission operating mechanism of the manual transmission has been modified.

[0024] specifically, Figure 2A , 2B and 3A, 3B show an embodiment of the automatic manual transmission and its shift operating mechanism according to the present invention. Here, the embodiment is still described by taking a five-speed transmission with five forward gears 1-5 and one reverse gear R as an example. Such as Figure 2B and 3A As shown, the shift operating mechanism 14 accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com