Steeply inclined coal seam strike advancing false dipping fully-mechanized coal mining

A pseudo-pitch and steep inclination technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of low labor intensity, low production efficiency, poor air passage, etc., and achieve good safety and high production efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

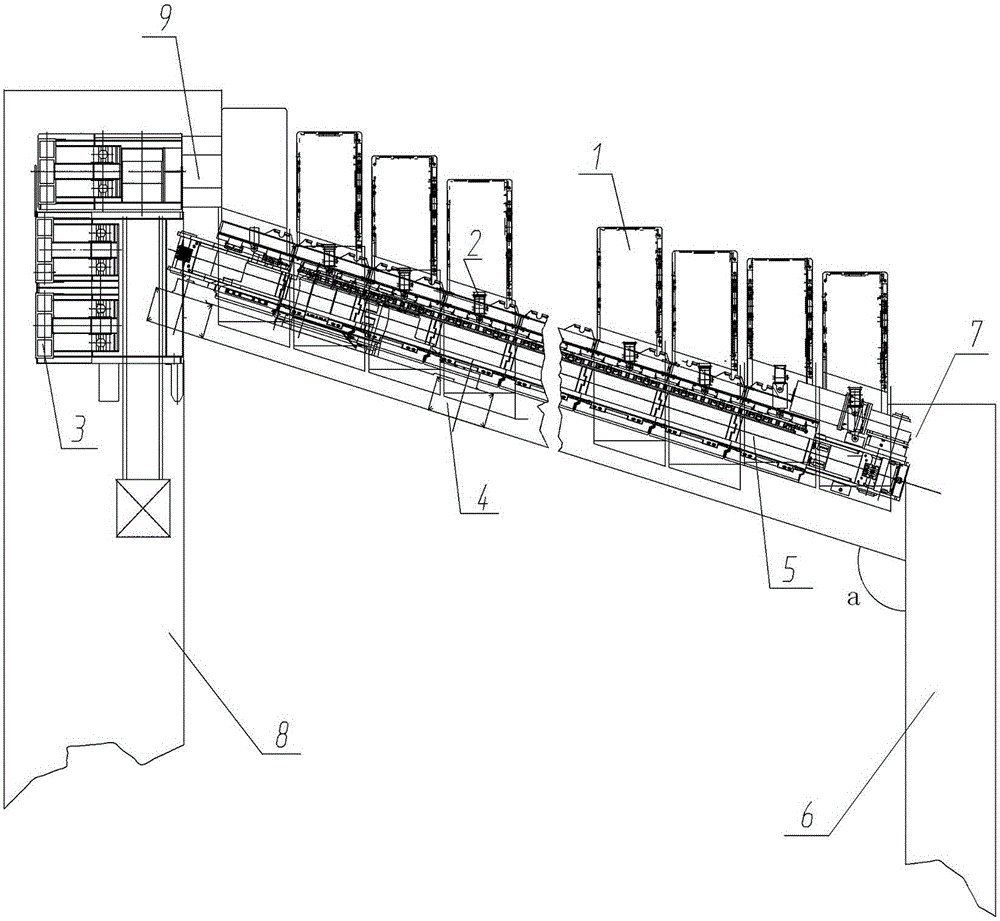

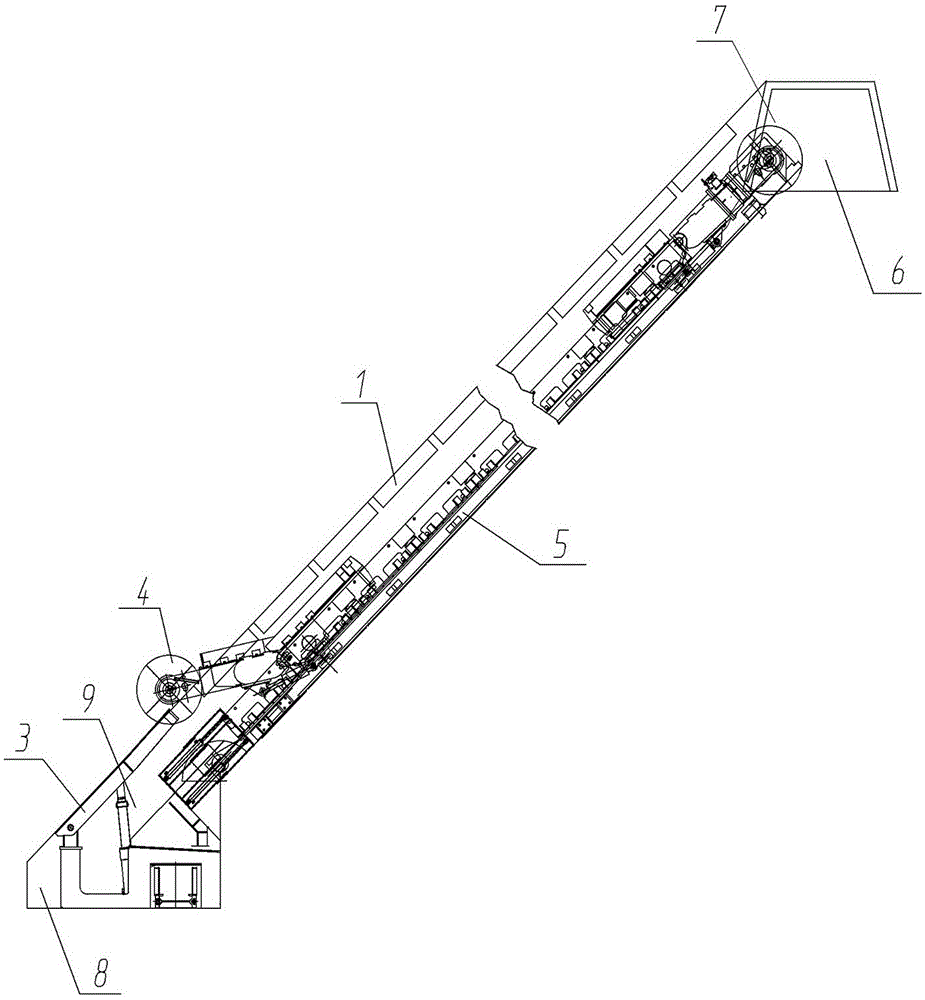

[0009] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 , figure 2 Shown: The trend of steeply inclined coal seam advances pseudo-inclined fully mechanized mining, mainly including hydraulic support 1, connecting head 2, end support 3, shearer 4, scraper conveyor 5, wind tunnel 6, upper exit 7, machine tunnel 8 , Next exit 9.

[0010] The trend of the steeply inclined coal seam advances the pseudo-inclination fully mechanized mining, such as figure 1 , figure 2 As shown, mining is carried out at the 5135 working face of Liziya South Coal Mine. The coal seam dip angle of this working face is 550-750°, the thickness of the coal seam is 1.3-3.8m, generally 1.9m, the strike length is 580m, and the inclination length is 47-60m. , machine lane 8, then use the cut eye to run through the ventilation lane 6 and the machine lane 8, the upper outlet 7 of the cut eye is ahead of the lower outlet 9, so that the coal minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com