Low damage rubber plug thickening agent used for hydraulic fracturing, rubber plug composition and application thereof

A technology of hydraulic fracturing and thickening agent, which is applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve the problem of silt/silty slug crack slippage effect is not obvious, control Low probability of success, relying on field experience and judgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1. On-site preparation of rubber plugs and static rubber plug treatment near wellbore multi-fracture process

[0071] 1. Preparation of rubber stopper thickener

[0072] The thickening agent in this embodiment is composed of surfactant, polyacrylamide, AMPS, methacryloxytrimethylammonium chloride, N-isopropylacrylamide, pimeloyl, and caustic soda in a mass ratio of 1:2 : 1:1:2:2:1 Mix in the reactor, stir evenly, control the temperature of the reactor at 180°C, the pressure at 10MPa, and the processing time for 2 hours, the obtained product is the thickener of this example, which is used for rubber stoppers thicken.

[0073] Rubber stopper base liquid formula:

[0074] Low-residue rubber stopper thickener + rubber stopper accelerator + clear water, rubber stopper cross-linking agent is a commercially available organic boron cross-linking agent, rubber stopper breaker (BL-PJ2 package from Dongfang Baolin Technology Development (Beijing) Co., Ltd. Ammonium pers...

Embodiment 2

[0092] Example 2, dynamic rubber plug to control crack slippage

[0093] Dynamic rubber plug control crack slip process:

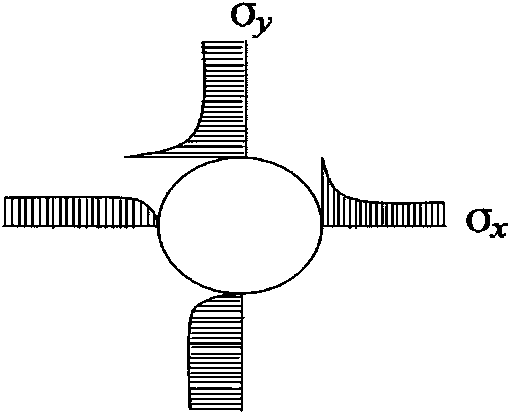

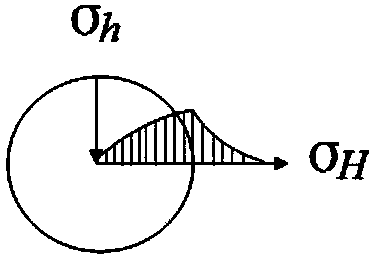

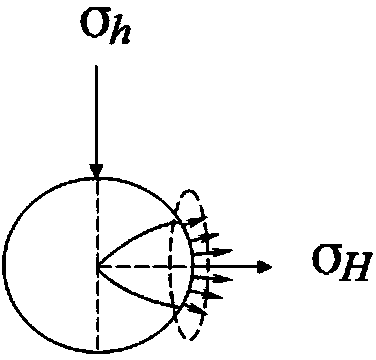

[0094] Before squeezing the rubber plug, a certain amount of fracturing fluid base fluid is used to create fractures, and then the rubber plug is pumped continuously at a low displacement, and the rubber plug is filled to the low stress position. After the rubber plugs have all entered the formation, continue to inject base fluid. At this time, since the low-stress area has been filled with high-viscosity rubber plugs, the fracture toughness of the low-stress area has been improved. The subsequent base fluid is directed from the blasthole along the direction of the fracture. The liquid advances, the rubber plug is pushed to both sides, when the front edge of the rubber plug is broken through ( Figure 9 ), the base fluid continues to create fractures forward and enters the normal fracturing operation.

Embodiment 3

[0107] Embodiment 3, dynamic rubber stopper controls crack height

[0108] Dynamic rubber plug control crack height process:

[0109] First use fracturing fluid-based hydraulic pressure to open the formation, and then inject the rubber plug with a low-displacement non-stop pump. Using the characteristics of high viscosity and poor fluidity of the rubber plug, it is filled in the highly extended part of the fracture to improve the fracture toughness of the extended part. The base fluid of the cracking fluid has low viscosity and good fluidity. It points in the fracture that has been opened, and forms a good fracture shape near the wellbore, so that the fracture can extend forward normally ( Figure 9 ).

[0110] Practical application example:

[0111] In layer 220III of Well XSH29, the fracture height is not easy to control. The fracturing section is 3550.6-3566.6m, the thickness is 16.0m, and the perforation section is 3557.0-3562.0m. It can be seen that the slippage of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com