Tensile test manufacturing method of synthetic crude fibers in concrete

A technology of tensile testing and production method, which is applied to the testing and production of synthetic crude fibers in concrete, and the tensile strength testing field of crude fibers. The effect of reducing the difficulty of test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Prepare the fixed plate for surface roughening:

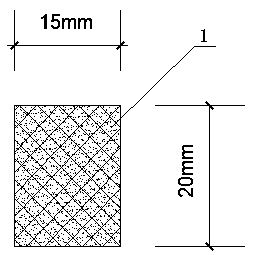

[0027] Such as figure 1 As shown, cut the bulky fixing plate material into a fixing plate 1 of 20 mm×15 mm, and ensure that the cut part is flat and smooth. Then, one side of the fixed plate 1 is polished with a file until the surface is rough, and the surface powder is removed to make the polished surface clean and tidy.

[0028] The above fixing plate material is a material suitable for bonding with synthetic thick fibers, and the thickness is 1.5-2 mm.

[0029] 2. Pretreatment of synthetic crude fiber:

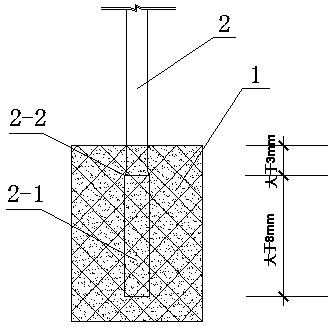

[0030] Squeeze both ends of the synthetic thick fiber 2 into a flat shape 2-1 with a vise, and the extruded length is not less than 8mm.

[0031] 3. Fixed synthetic crude fiber:

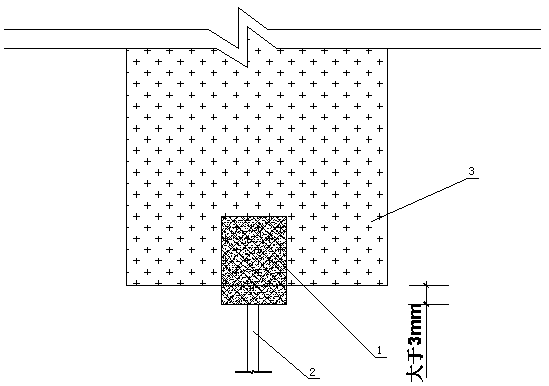

[0032] Such as figure 2 As shown, the two ends of the pretreated synthetic crude fiber 2 are respectively bonded between two polished fixing plates 1, wherein the inner end 2-2 of the processed crude fiber 2 should be stretched into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com