Method for automatic resistance adjustment of foil resistance strain gauge and automatic resistance adjustment equipment

A resistance strain gage and strain gage technology, applied in non-electric variable control, control/regulation systems, instruments, etc., can solve the problem of inability to accurately measure the real resistance value of the strain gage in real time, the adjustment amount of the resistance value that cannot be controlled, and the strain gage. Sensitive quality has a great impact, achieving the effect of batching, ensuring positioning accuracy and repeatability, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

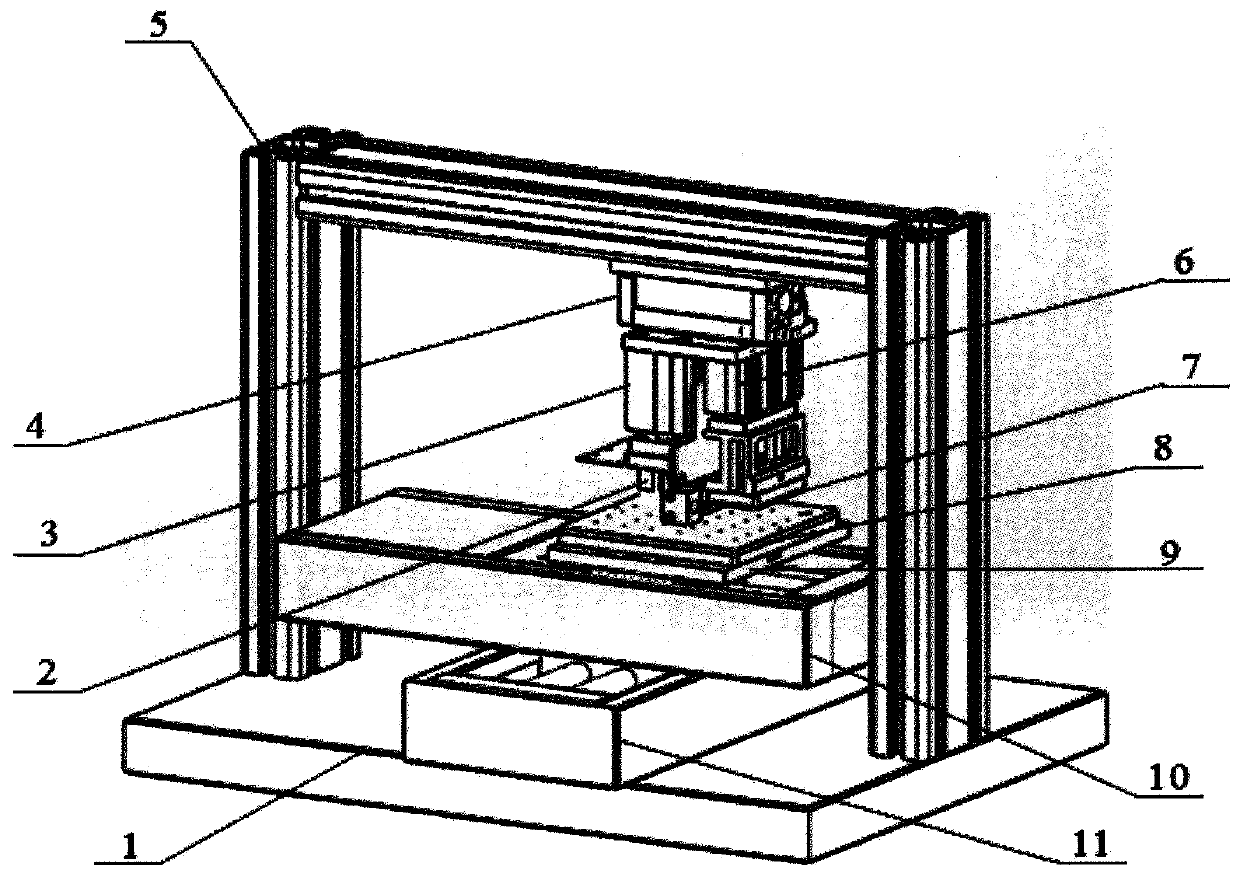

[0044] The present invention will be further described below with reference to the accompanying drawings.

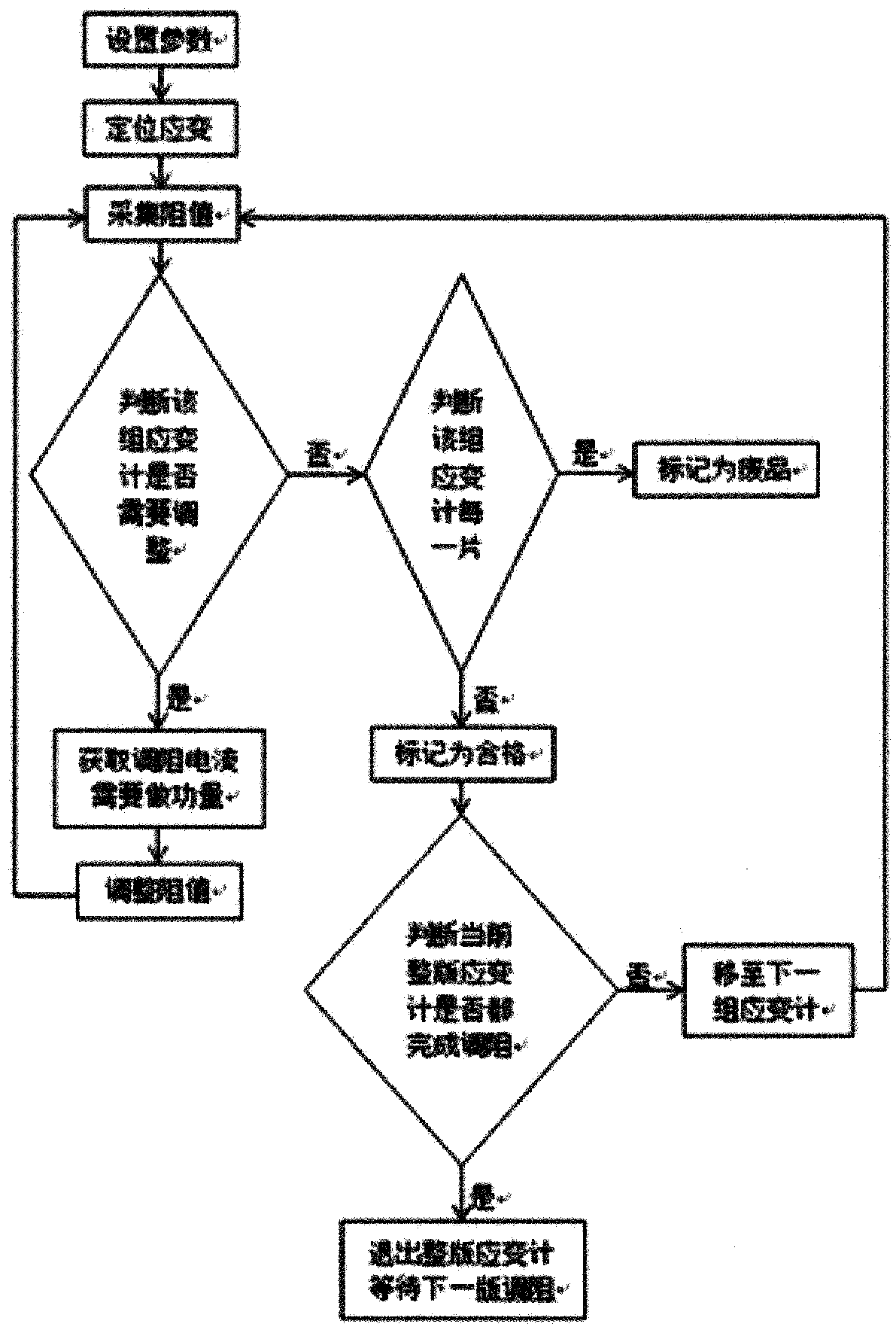

[0045] refer to figure 1 , 2 , 3, 4, the method for automatically adjusting the resistance of the foil resistance strain gauge provided by the present invention includes the following steps:

[0046] Parameter setting: Set the resistance adjustment parameters of the foil resistance strain gauge according to different types of foil resistance strain gauges and different requirements, calibrate according to the displacement deviation of the mechanical structure, set the calibration parameters of the mechanical structure, and set the calibration parameters according to the foil resistance strain gauge. Set the type parameters of the type resistance strain gauge;

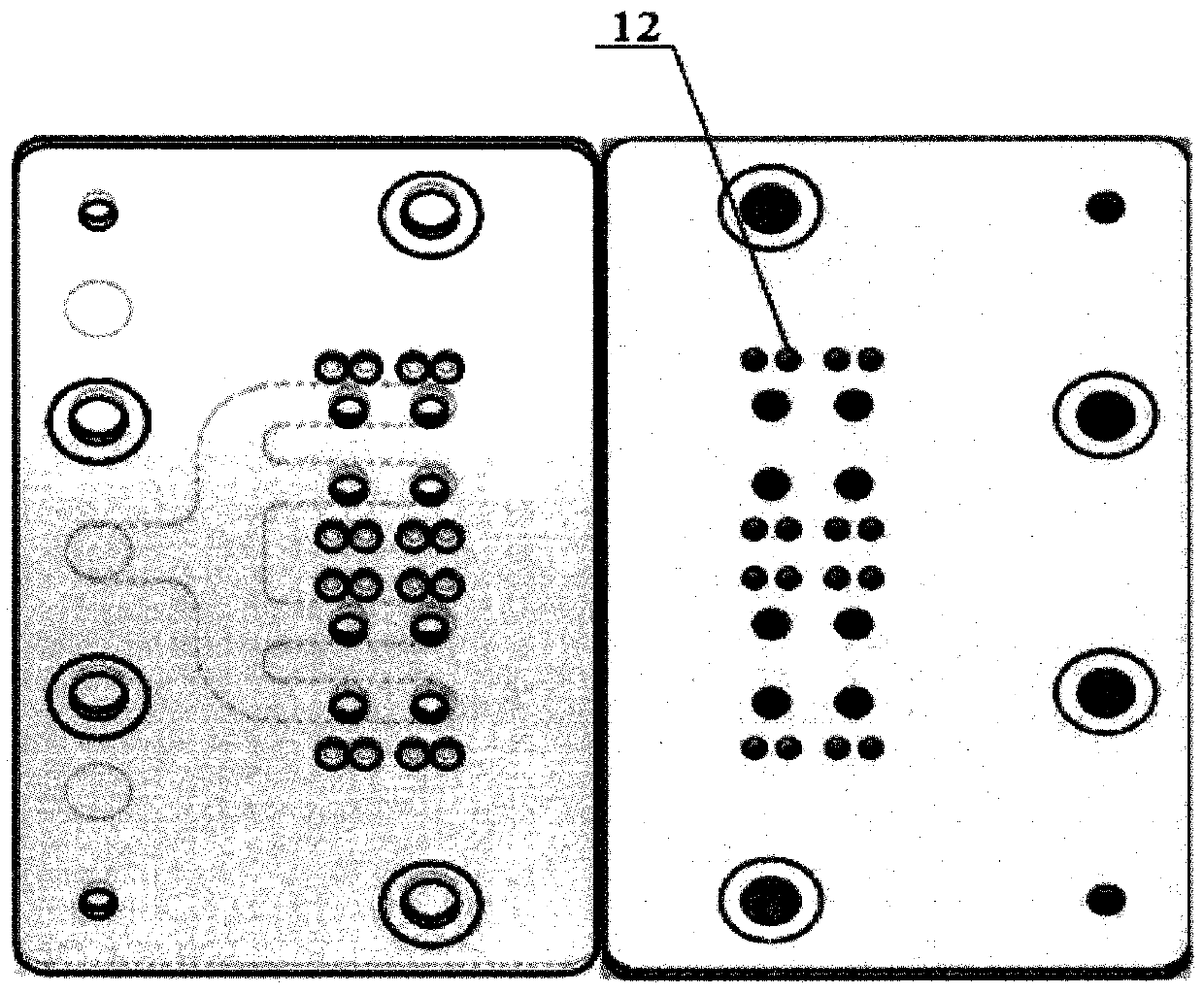

[0047] Automatic positioning: use a punching machine to automatically identify the positioning points reserved by the foil resistance strain gauge, make two positioning mark round holes on the two positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com